Custom Components & Full Assemblies CNC, Injection, Casting & More

From precision CNC machined parts to injection molded housings, die cast components, rubber & silicone parts, extrusions and full electromechanical assemblies — we design for manufacturability and deliver prototype → NPI → volume production with robust quality systems.

- Multi‑process capability: CNC, injection molding, die casting, extrusion and sheet metal

- End‑to‑end: design for manufacturing, tooling, testing & assembly

- Global fulfillment: DDP, VMI and warehousing support including USA Dallas hub

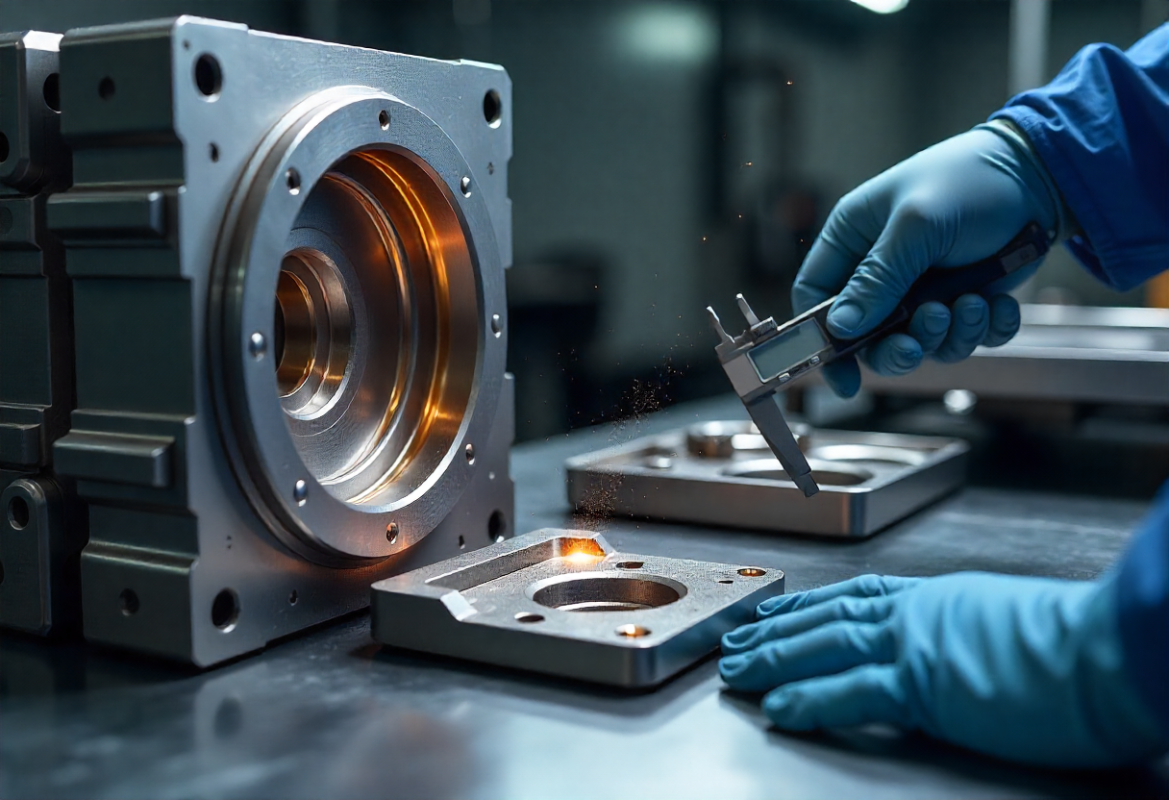

CNC Machining

Injection Molding

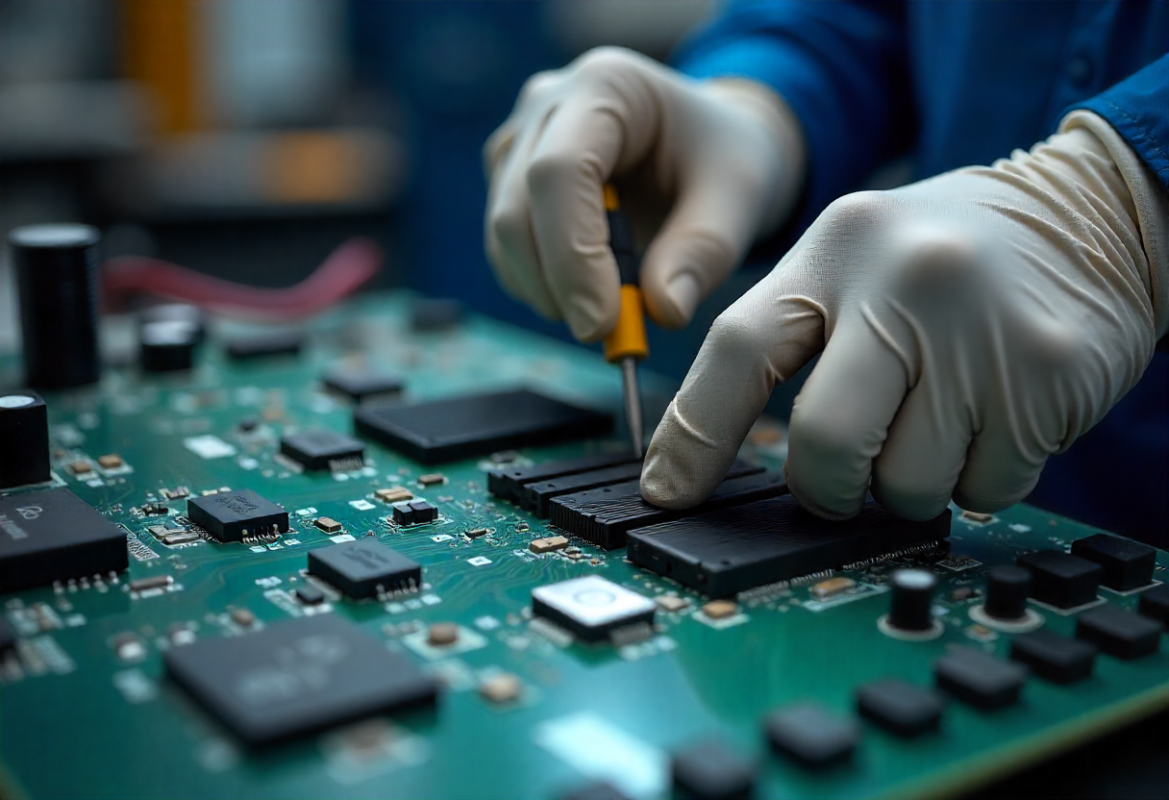

Assemblies

Full box build, wiring, testing and finished goods.

What We Make

CNC Machined Parts (Metal & Plastic)

Injection Molded Components

Die Casting & Extrusion

Sheet Metal, Stamping & Forming

Rubber & Silicone Molding

Casting, Forging & Welding

Manufacturing Capabilities

CNC Machining

High‑precision 3/4/5‑axis milling, Swiss turning and multi‑axis CNC for complex parts. Typical tolerances down to ±0.01 mm with advanced fixturing and in‑process probing.

Prototype and production molds, multi‑shot molding, LSR and insert molding. DFM reviews to balance cycle time, warpage and mechanical properties.

Die Casting & Secondary Machining

Rubber & Silicone Molding

Sheet Metal & Stamping

Assembly & System Integration

Materials & Finishing

We work with a broad material set to meet mechanical, thermal and regulatory requirements — including Aluminum 6061/7075, ADC12, A380; stainless steels (304/316/420); copper & alloys; zinc (Zamak); engineering plastics (PA, POM, PEEK, PC/ABS); and LSR/silicones.

Surface treatments

Anodizing (standard & hard), powder coat, wet paint, passivation, nickel/chrome/zinc plating, black oxide, polishing, sandblasting, laser marking, silk screen and pad printing.

Performance coatings

Thermal coatings, corrosion resistant coatings, anti‑fingerprint and UV stabilizers tailored to end‑use environments.

Tooling & Mold Engineering

In‑house mold design, EDM, CNC tool machining and tool trial capability. We design injection molds, die casting dies, extrusion tooling and progressive stamping tools with lifecycle planning and maintenance programs.

Mold life & maintenance

Planned maintenance, spare components, and mold refurbishment programs to reduce downtime and protect NPI schedules.

Prototype → NPI → Mass Production

Our development path guides you from quick-turn prototypes (CNC, 3D print, soft tooling) through EVT/DVT/PVT validation to PPAP/FAI and scaled production. We provide Cpk studies, process window definition and supply chain readiness reviews.

Validation & documentation

FAI reports, PPAP submissions, Cpk capability studies, PFMEA, process documentation and full traceability for regulated industries.

Quality, Testing & Certifications

ISO 9001 aligned processes, AQL inspection, CMM and 3D scanning, SPC and material certifications (RoHS, REACH, UL, FDA where applicable). We perform mechanical testing, environmental testing and lifecycle validation per customer specs.

Inspection & metrology

CMM, optical comparators, in‑line gauges, and custom inspection fixtures to ensure tolerance compliance and repeatable assembly quality.

Industries We Serve

Automotive & EV

Powertrain parts, thermal enclosures, brackets and EV upgrade components with automotive grade processes.

Power Electronics & Energy

Housings, busbars, cold plate brackets and assemblies for converters and inverters.

Medical & Lab

Biocompatible plastics, precision machined components and clean assembly workflows.

Telecom & Datacom

Racks, modules, and injected parts for high-density networking equipment.

Industrial & Robotics

Robust castings, machined parts and assemblies for automation systems.

Consumer & Audio

Aesthetic finishing, mass automation, speaker and audio structural components.

Case Studies & Examples

Die Cast Housing for EV Charger