Manufacturing Overview — Multi‑Process Capability from Prototype to Volume

We combine multi‑process manufacturing expertise, NPI discipline and modern automation to deliver components and assemblies across metals, plastics and elastomers. Our capabilities cover CNC machining, injection molding, die casting, extrusion, stamping, casting, rubber molding, welding (laser/Friction Stir), surface finishing and full electromechanical assembly.

- Prototype → validation → pilot → mass production with PPAP/FAI and process windows

- Flexible capacity: low volume bespoke runs to high volume automated production

- Quality systems, traceability, digital manufacturing (MES/SPC) and global fulfillment

Precision CNC Machining

Multi‑axis machining for tight tolerances, complex features and advanced fixturing—ideal for prototypes and production parts requiring repeatable accuracy.

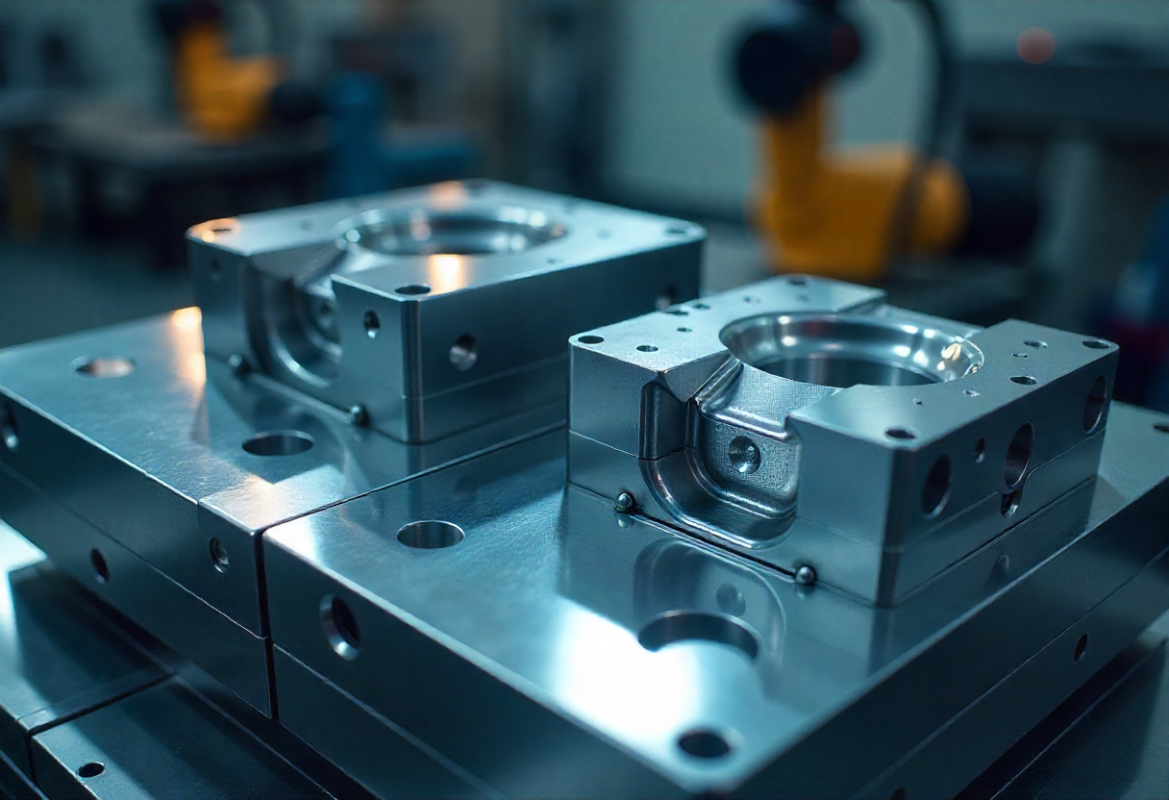

Injection Molding & Tooling

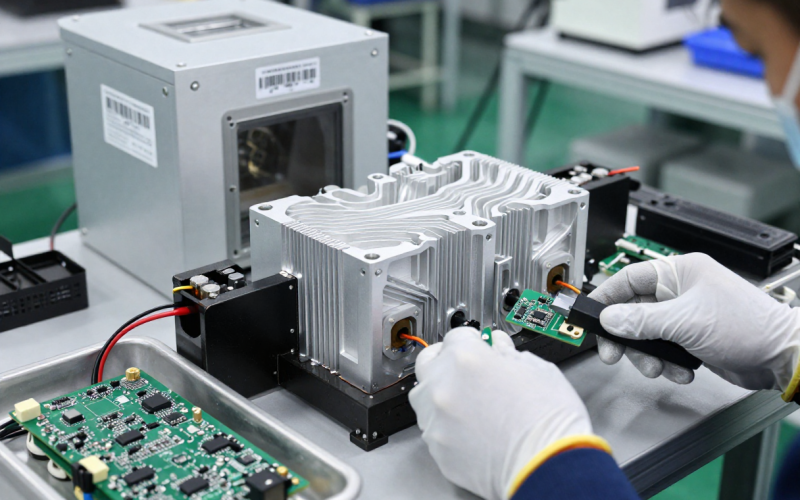

Assembly, Test & Final Inspection

Core Manufacturing Processes

CNC Machining

Injection Molding

Prototype aluminum tools, high‑cavity hot runner steel molds, overmold & insert molding for multi‑material assemblies.

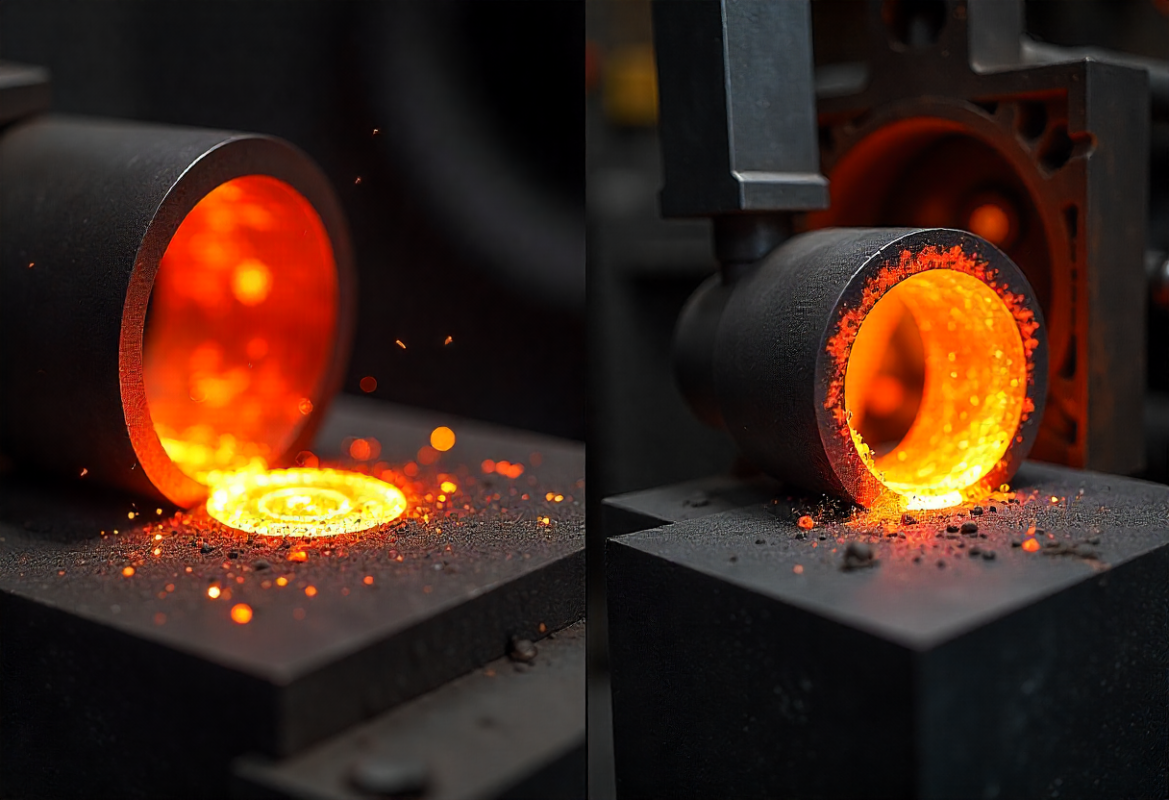

Die Casting & Forging

Cold‑chamber aluminum and hot‑chamber zinc die casting, closed‑die forging for high strength components.

Extrusion & Profiles

Aluminum extrusions, rubber/silicone extrusion dies, co‑extrusion and post‑processing (cut, machine, anodize).

Sheet Metal & Stamping

Progressive dies, transfer tooling, deep draw and spinning for housings and structural sheet parts.

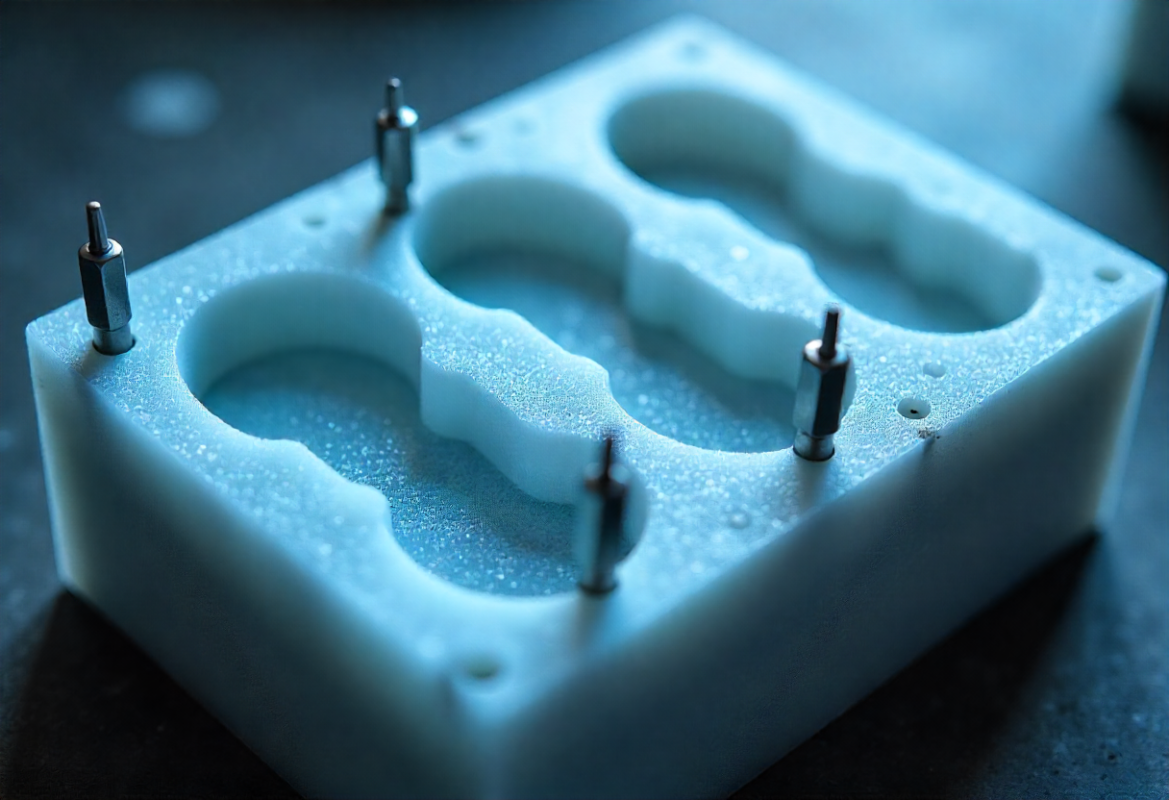

Rubber & Silicone Molding

LSR injection, compression, transfer molding with post‑cure and trim automation; cleanroom options for medical parts.

Casting (Sand/Investment/Gravity)

Pattern making, gating/riser optimization, CNC finishing and NDT for cast components.

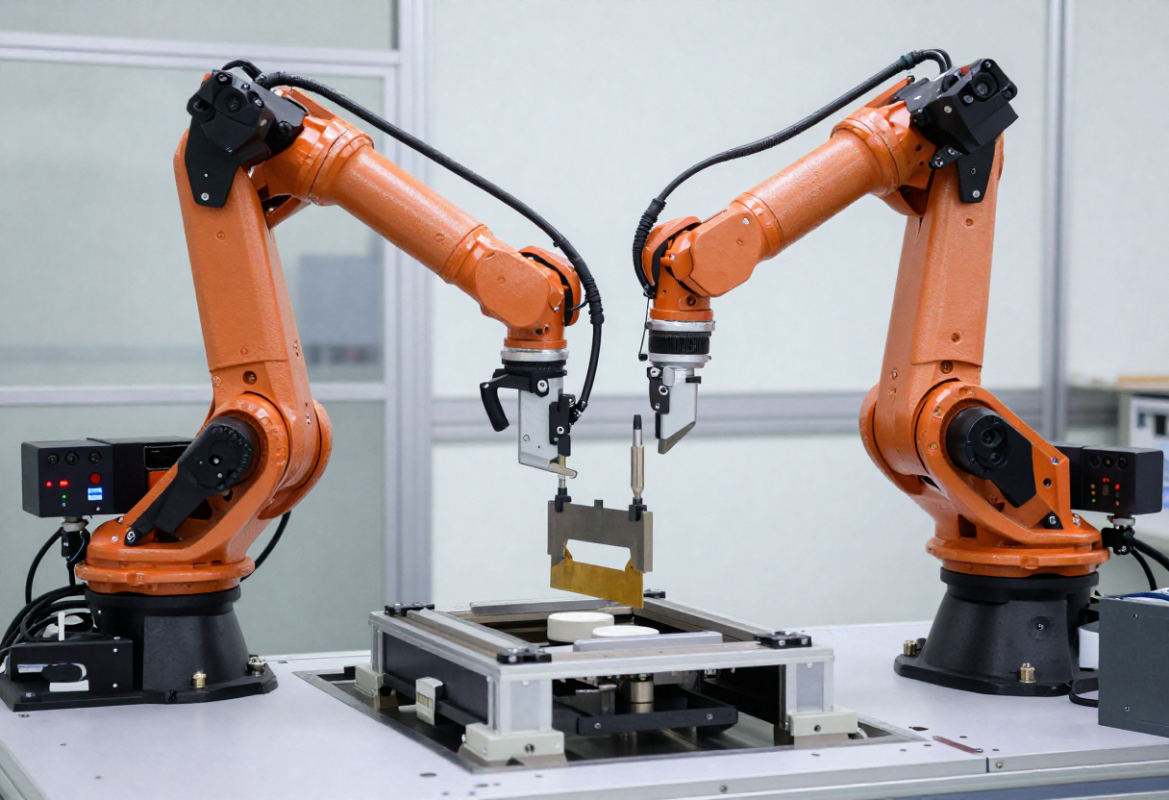

Welding & Joining

Laser, TIG/MIG, FSW, braze and automated robotic welding fixtures for thermal & structural integrity.

Prototype → Validation → Production (NPI & Ramp)

Our NPI framework moves designs from concept to production with structured gates: DFM review, prototype validation, EVT/DVT/PVT testing, PPAP/FAI generation and controlled production ramp. We minimize launch risk through DFMEA/PFMEA collaboration, pilot runs, capability studies and early quality gates.

Typical NPI steps

- DFM/DFMA review and process selection

- Prototype parts (3D print, CNC soft‑tool, urethane cast)

- Tooling build & tryout (molds/dies), trial runs and FAI

- Pilot production with SPC/Cpk studies and process window definition

- Controlled ramp to volume with supply chain synchronization

Automation, Robotics & Digital Manufacturing

We design automation into production solutions: robotic load/unload, vision alignment, automated inspection, palletized quick‑change systems and MES integration. Digital manufacturing tools (MES, SPC, OEE dashboards) provide traceability, per‑unit records and predictive maintenance triggers for tooling and equipment.

Typical integrations

- Robot cells with vision guided part placement and torque/force feedback

- Automated test fixtures for ICT/FCT and burn‑in racks

- MES connectivity for serialized traceability and lot reporting

Quality Systems & Test Capabilities

Manufacturing operates to ISO 9001 standards with SPC, incoming inspection, IPC acceptance (electronics), AQL sampling, CMM and 3D scanning for dimensional control. We support FAI/PPAP, Cpk studies, PFMEA and DOE as part of robust NPI and production controls.

Inspection & metrology

- CMM, optical 3D scanning and inline gauging

- Hardness, tensile, microsectioning and metallography

- CT/X‑ray and ultrasonic NDT for castings and welded assemblies

Environmental & functional testing

- Thermal chambers, vibration, shock, salt spray and IP/IK testing

- Thermal performance testing for cold plates & heat sinks

- EMC/EMI testing coordination for electronic modules

Supply Chain, Packaging & Global Fulfillment

We integrate supplier qualification, long‑lead procurement, dual sourcing and inventory models (VMI, consignment) to mitigate risk. Packaging engineering ensures shock and vibration protection for transit; global fulfillment and US Dallas hub options support DDP and fast aftermarket delivery.

Logistics services

- Custom kitting, serialized packing lists and barcoding

- DDP, EXW, FOB and other trade terms with customs support

- Warehousing, VMI, JIT replenishment and repair/refurb workflows

Sustainability & Continuous Improvement

We pursue energy and waste reduction, recyclable design, optimized packaging and material substitution where appropriate. Continuous improvement via Kaizen, root cause analysis and SPC reduces scrap and improves yield while lowering carbon and cost per part.

Practical initiatives

- Optimize nesting/strip layouts to reduce scrap

- Favor recyclable materials and simplified assemblies

- Monitor energy consumption and reclaim process heat where possible

Capacity, Lead Times & Scalability

Lead times vary by process, complexity and tooling. Rapid prototypes can be delivered in days; prototype tooling 1–4 weeks; production tooling 6–20+ weeks. We scale using automated lines, multi‑shift operations and partner networks to meet high volume demands while maintaining quality.

| Process | Typical Lead Time | Notes |

|---|---|---|

| Prototypes (3D / CNC) | Days – 2 weeks | Quick form/fit validation |

| Prototype tooling (aluminum) | 1–4 weeks | Low shot life for validation |

| Production tooling (molds/dies) | 6–20+ weeks | Depends on complexity & heat treat |

| Electronics build & test | 4–12 weeks (NPI) | PCB lead time critical path |

Representative Manufacturing Projects

EV Inverter — Cold Plate & Module Production

Full supply: CNC machined cold plates, FSW sealing, die cast housings, populated PCBs, harnesses and final box‑build with environmental testing and serialized traceability for automotive release.

High‑Volume Consumer Fixture

Transitioned from CNC prototypes to injection molded parts with multi‑cavity tooling, automated assembly and vision inspection — reduced unit cost by 60% and scaled to 100k+ units/year.

Frequently Asked Questions

How quickly can you evaluate my design for manufacturability?

Upload CAD and nominal volumes; our engineering team typically returns DFM feedback and recommended processes within 24 business hours.

Do you support small pilot runs before full volume?

Yes — pilot builds with controlled yields, capability studies and documented process windows are standard before volume ramp.

How is quality data reported during production?

We provide per‑lot and per‑unit test records, SPC dashboards, FAI/PPAP packages and serialized traceability as required by program needs.

Plan Your Manufacturing Path

Upload part CAD, target volumes and performance requirements. We’ll respond with a recommended manufacturing route, NPI plan, tooling options and estimated lead times — typically within 24 business hours.