Heat Pipes & Vapor Chambers — Spreading, Routing & Compact Thermal Solutions

We develop planar vapor chambers and flattened heat pipes that reduce hotspot temperatures and enable low‑profile, high‑density electronics. From wick selection and chamber fabrication to hermetic sealing and CFD correlation, we deliver spreaders and routing elements engineered for prototyping and high‑volume manufacture.

- Thin vapor plates for two‑dimensional spreading and hotspot mitigation

- Flattened/embedded heat pipes for thermal routing and hybrid assemblies

- Validated by CFD, hermetic testing and production process controls

Vapor Chambers

Ultra‑thin spreaders for compact electronics and optics cooling.

Hybrid Cold Plate Assemblies

Combine vapor plates with cold plates for highest heat flux management.

Server Vapor Plate

Validated rack‑level performance with CFD and thermal cycling.

What is a Heat Pipe or Vapor Chamber?

A vapor chamber is a sealed, planar device that spreads heat across its surface using phase change and a capillary wick; it turns localized high‑flux heat into a more uniform temperature field. A heat pipe is a sealed tube (or flattened form) that transports heat efficiently along a path. Both technologies use working fluids and wicks to move heat with very low temperature drop compared with solid conduction alone.

Typical uses: hotspot mitigation, low‑profile spreaders for optics and small electronics, and routed thermal paths in constrained mechanical layouts.

Flatten Hotspots — Improve Reliability

Vapor chambers flatten temperature gradients across a surface, reducing peak junction temperatures and improving component lifetime.

Enable Low Profile Designs

Thin vapor plates (often < 2 mm) allow designs with minimal z‑height while still achieving excellent thermal spreading.

Route Heat Around Constraints

Flattened heat pipes are ideal where a thermal path must be routed around connectors or structural features while maintaining low thermal resistance.

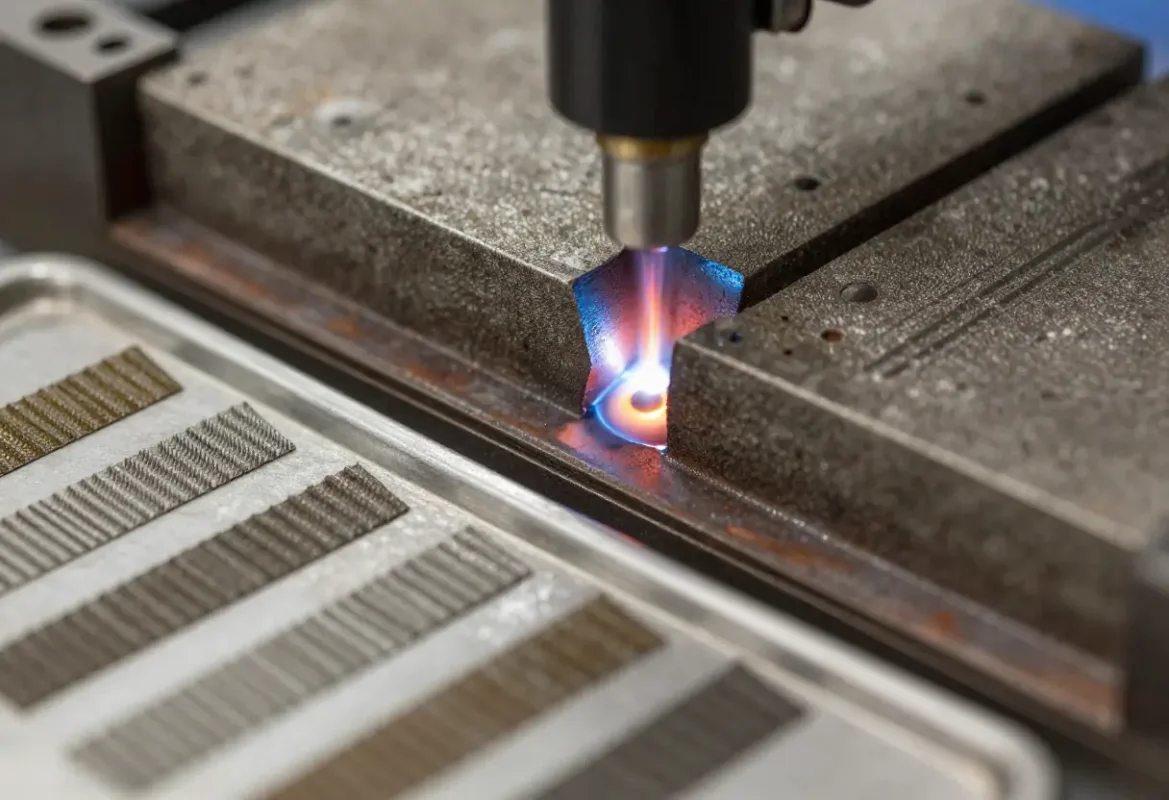

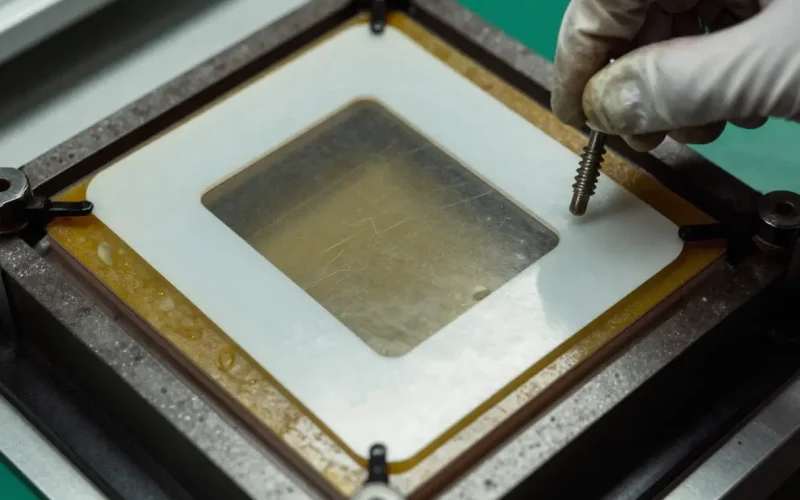

Manufacturing & Fabrication

We fabricate chambers using stamping, rolling, or CNC formed envelopes and produce wicks via sintering, grooving, or composite methods. The working fluid is filled under controlled vacuum and charged to the specified mass and pressure, then sealed via laser welding or brazing. Post‑seal verification includes leak testing and batch thermal sampling.

Process controls

Vacuum bake profiles, fill mass control, seam inspection, helium/vacuum leak testing and batch Rθ sampling to ensure repeatable performance in production.

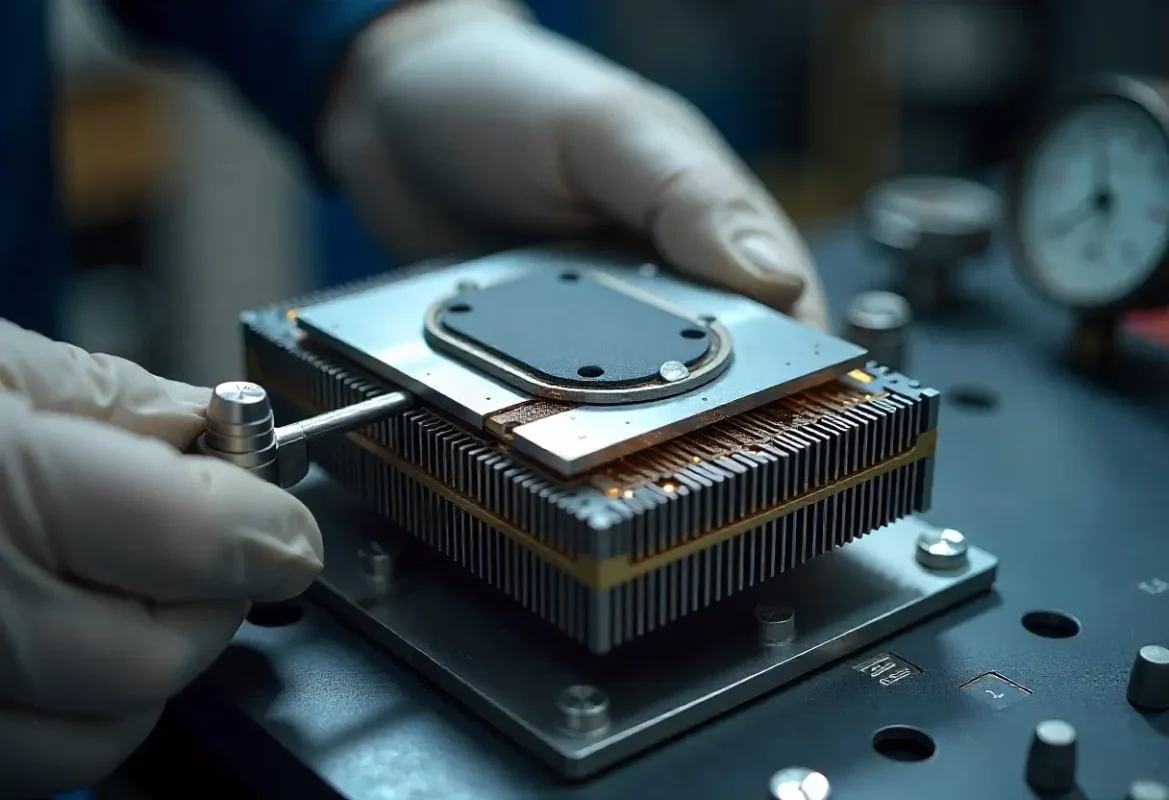

Integration & Hybrid Assemblies

Vapor chambers and heat pipes are often combined with cold plates, skived heatsinks or housings. We provide brazing, soldering, adhesive bonding, and mechanical mounting strategies to maintain low interface thermal resistance and reliable mechanical fixation.

Assembly options

Brazed interfaces, selective soldering, adhesive bonds with thermally conductive adhesives, and mechanical clamps for serviceable designs.

Materials, Wicks & Surface Treatments

Standard construction uses high‑conductivity copper for chambers and wicks. We offer copper alloys for increased strength or better braze compatibility. Wick choices (sintered powder, grooved, composite) are selected by orientation, heat flux and lifecycle requirements. Plating options (nickel, tin) improve corrosion resistance and solderability.

Environmental considerations

We evaluate galvanic interactions, ambient exposure and coolant environment to recommend barrier coatings or isolation strategies for long‑term reliability.

Representative Geometry & Performance Ranges

Below are typical ranges used as starting points for design. Final values are tuned to your power map, envelope and reliability targets.

Thickness

0.8 — 6.0 mm (vapor chambers); flattened pipes 1.0 — 6.0 mm

Effective Lateral Conductivity

~1,000 — 30,000 W/m·K depending on geometry and wick

Local Heat Flux Capability

>200 W/cm² with tailored wick and vapor paths

Typical Sizes

20×20 mm up to 300×300 mm or custom shapes

| Parameter | Typical Range | Notes |

|---|---|---|

| Chamber thickness | 0.8 — 6.0 mm | Thin for low profile; thicker for rigidity |

| Lateral conductivity | 1,000 — 30,000 W/m·K | Chamber geometry & wick dependent |

| Max local heat flux | > 200 W/cm² | Requires optimized wick and vapor return |

| Operating temp | -40 °C to +150 °C | Working fluid selected to match range |

| Material | Copper / alloys | Nickel/tin plating available |

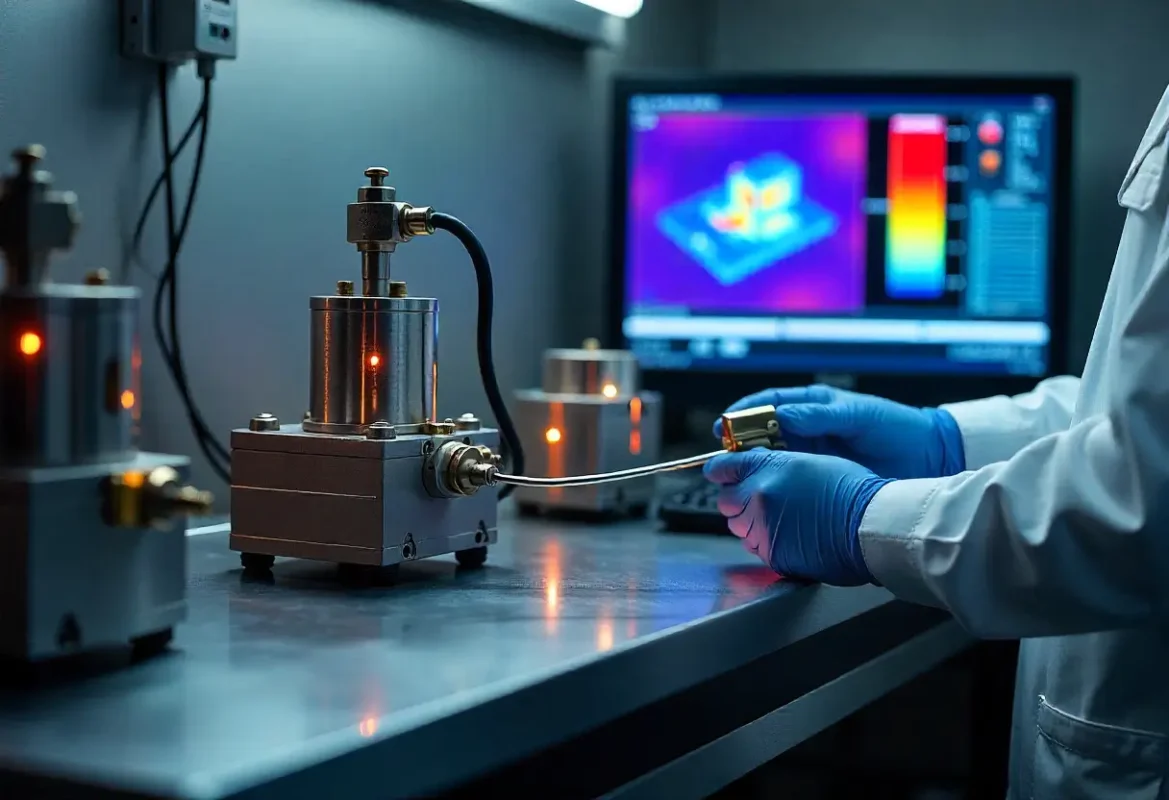

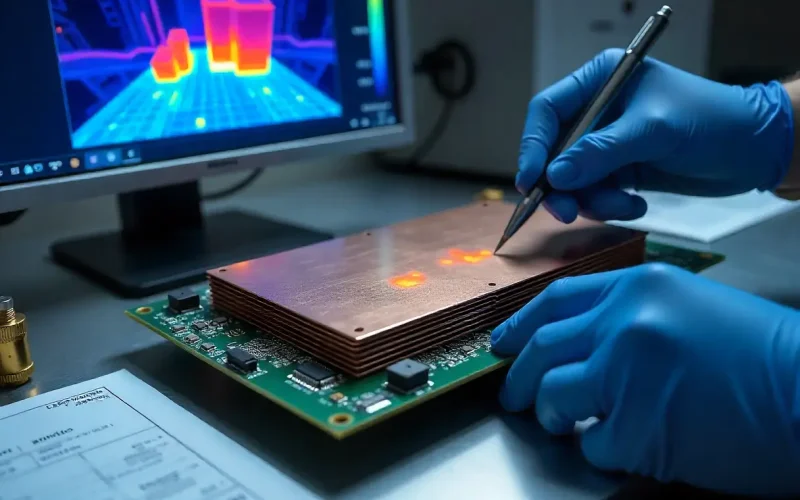

CFD Correlation & Thermal Characterization

We couple CAD‑linked CFD and conjugate heat transfer simulations with prototype testing to quantify thermal resistance, temperature distribution and transient response. Correlated models shorten iteration cycles and reduce prototype count while giving confidence in production performance.

Deliverables

CFD reports (steady & transient), prototype thermal maps, Rθ measurements and design recommendations for wick and interface selection.

Qualification & Reliability Testing

Typical tests

Leak tests, IR/TC thermal mapping, transient response, thermal cycle and vibration summaries.

Applications

Power Electronics & EV Inverters

Reduce junction temperatures in SiC/IGBT stacks with thin spreaders to meet compact inverter constraints.

Telecom & Datacom

Even temperature distribution across line cards and network modules to lower fan power and improve reliability.

Compute & Accelerators

Vapor plates paired with cold plates for dense rack solutions and accelerator modules.

Representative Projects

EV Inverter Vapor Chamber Integration

22% junction ΔT reduction vs conventional spreader; met 6 mm stack height and passed leak and thermal validation — EVT→DVT→MP in 18 weeks.

Blade Server Vapor Plate

Custom 220×120 mm vapor plate for an accelerator module validated with rack‑level thermal testing and CFD correlation.

Frequently Asked Questions

How thin can a vapor chamber be?

We produce vapor chambers under 2.0 mm for many applications. Achievable thinness depends on required spread performance and handling/assembly constraints.

Do vapor chambers depend on orientation?

Vapor chambers are generally less gravity sensitive than long heat pipes due to the wick providing planar return. For gravity-critical applications we design and test specific wick structures to ensure orientation robustness.

Can vapor chambers be integrated with cold plates?

Yes — we provide brazing, soldering and mechanical mounting options, and validate interface thermal resistance during prototype testing.

Ready to Specify a Vapor Chamber or Heat Pipe?

Upload your power map, geometry and target ΔT. Our thermal engineers will return feasibility notes, wick recommendations and a prototype plan — typically within 24 business hours.