Mass Production Scaling Framework

🛠️ Tooling NRE 🤝 Supplier Qual

📊 SPC / Cpk 📦 VMI / JIT

🚚 DDP Logistics ✅ Warranty Cut

Reliable Volume • Controlled Cost • Low Warranty Risk

Strategic & Foundational

Clear Tooling & NRE Strategy

Assess tooling options—pilot fixtures, bridge tooling, production tooling—and amortize NRE to balance risk and unit cost at expected volumes.

Supplier & Process Qualification

Supplier audits, capability studies, PPAP/FAI coordination and build plans to ensure suppliers meet throughput and quality targets.

Supply Chain & Logistics

Packaging engineering, DDP fulfillment, VMI/JIT programs and customs/duty optimization to reduce lead times and inventory cost.

Five Stages of a Successful Ramp

Pilot & Proof

Low-volume pilot to validate process and assembly flows before heavy NRE.Tooling & Jigs

Plan and build production tooling and fixtures aligned to target cycle times and tolerances.Process Qualification

Confirm supplier readiness through PPAP/FAI audits and SPC/Cpk studies, establishing rigorous process windows for all critical-to-quality (CTQ) parameters.Scale Operations

Volume ramp with VMI/JIT, line balancing, and takt-time optimization to meet demand consistent with capacity.Continuous Improvement

Ongoing yield optimization, change control, warranty root cause closure, and lifecycle cost reduction.Capability-Focused

Tooling & NRE

Supplier Qualification & Capacity

Process Capability & SPC

Supply Chain, Packaging & Logistics

VMI / JIT & Inventory Strategies

Key Metrics We Track

Yield %

First pass and overall yield trends during ramp

Cpk (CTQs)

Process capability on critical dimensions and outputs

Throughput

Parts per hour and takt adherence

On-time Delivery

Supplier fill rate and DDP arrival performance

| Metric | Target | Action if off-target |

|---|---|---|

| First Pass Yield | > 95% | Root cause & containment, immediate process correction |

| Cpk (CTQ) | > 1.33 (1.67 preferred) | Process stabilization, tooling correction, tolerance evaluation |

| On-time Delivery | > 98% DDP | Supply rebalancing, expedite lanes, alternate sourcing |

Continuous Improvement & Post‑SOP Support

Warranty & Field Reliability

We run warranty analytics and closed-loop failure analysis to reduce root causes, track returns by SKU and supplier, and implement corrective actions with verification in production.

Lifecycle Cost Management

Review total landed cost periodically: duty, freight, packaging, warranty, rework and obsolescence to seek additional cost reduction opportunities.

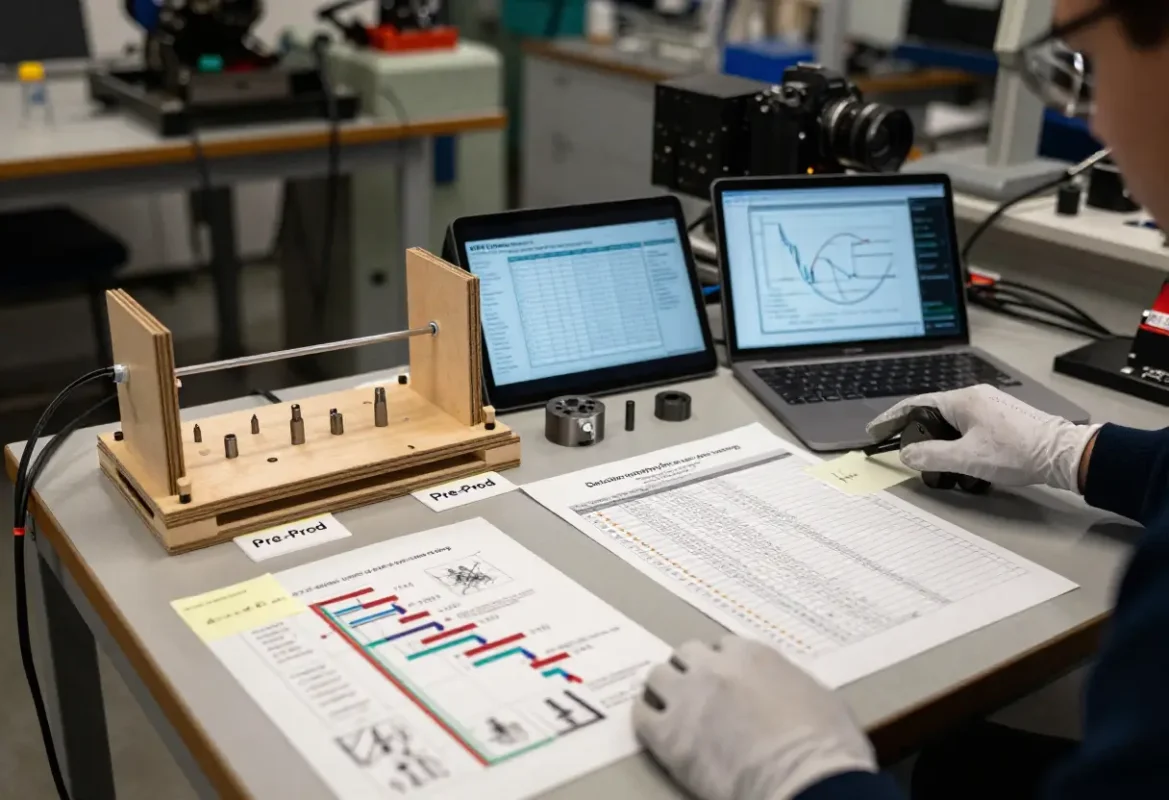

Case Study — Scaling a Power Module Program

We supported a power module program through a six-month ramp from pilot to 50k units/year. Activities included tooling consolidation, supplier second-sourcing, establishing SPC dashboards, packaging redesign (reduced damage 67%), and a VMI program with Dallas warehouse stocking. Outcome: achieved target output with Cpk > 1.67 on CTQs and reduced time-to-ship by 40%.

Starter Ramp Checklist

| Item | Why it matters |

|---|---|

| Tooling roadmap | Defines NRE timing and cost amortization |

| CTQ list & measurement plan | Focuses capability studies and SPC |

| Supplier audit checklist | Confirms capacity & quality systems |

| Packaging & DDP plan | Reduces transit damage and duty surprises |

| VMI/JIT parameters | Reduces inventory and improves assembly flow |