PPAP · FAI · Cpk · Process Window Setup

📑 FAI / PPAP 🧾 Material Traceability

📊 Cpk Targets + SPC Dashboards ⚙️ Control Plan / PFMEA

Verified Capability • Traceable First Articles • SOP Handover

Production Readiness & Process Qualification

What This Service Covers

We prepare and manage FAI/PPAP deliverables, perform capability (Cpk) studies on CTQs, run SPC implementations, and set process windows and control plans required for SOP. Work includes supplier coordination, metrology correlation and documentation for audits.

When You Need It

Before SOP, after process changes, when onboarding new suppliers, or when capability metrics need improvement to meet customer or regulatory requirements.

Qualification Flow (high level)

Pre‑FAI Planning

Agree sample sizes, measurement plan, CTQs, material traceability and acceptance criteria before first article builds.

First Article Builds

Run first article/sample builds under controlled process, capture dimensional, material and functional data.

Measurement & Metrology

CMM, 3D scan and inspection against drawings; GR&R and fixture verification to ensure measurement validity.

Capability Analysis

Calculate Cp, Cpk and process performance for CTQs; identify gaps and root cause if below targets.

Control Plan & Handover

Finalize control plan, PFMEA updates, SPC charts and supplier instructions, then approve PPAP/FAI for SOP release.

From Prototype to Mass Production

First Article Inspection (FAI)

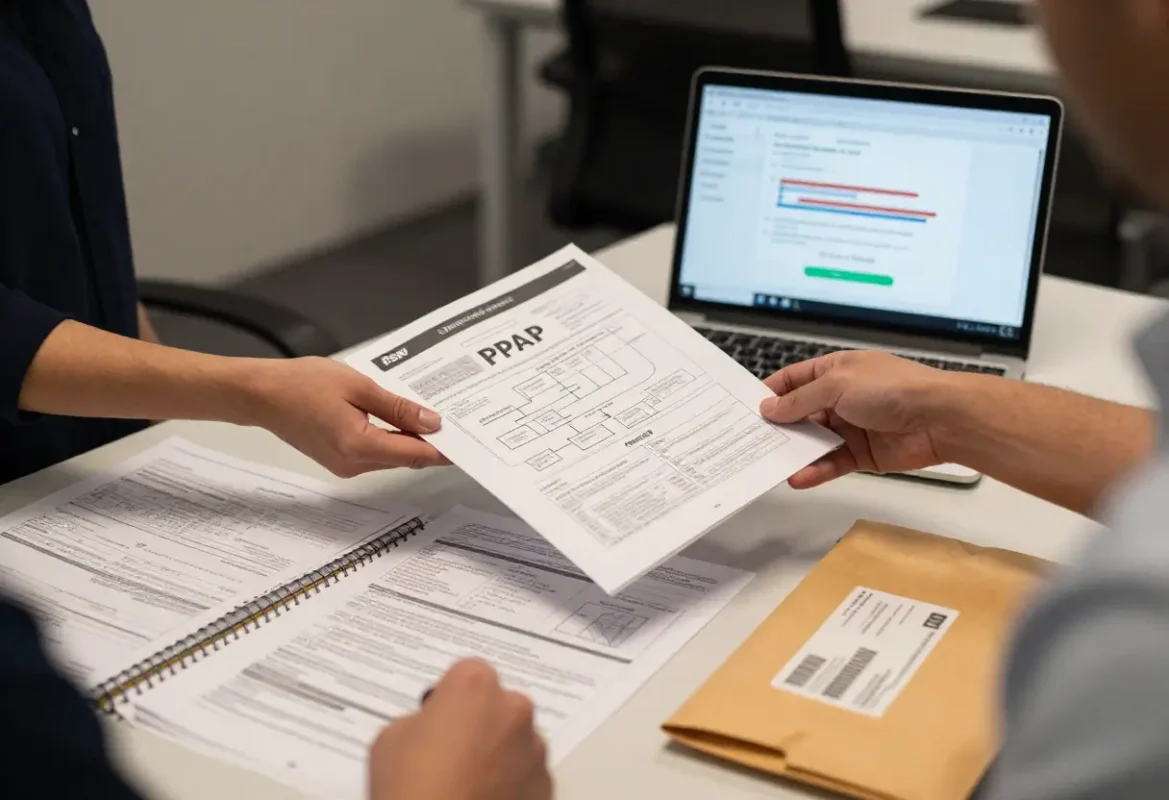

PPAP & Customer Submission

Cpk & Statistical Capability

Capability studies on critical dimensions and process outputs. We report Cp/Cpk, Ppk, short‑term and long‑term capability, and advise on corrective actions or tolerance adjustments to meet requirements.

SPC Implementation & Process Windows

| Item | Purpose | Typical Output |

|---|---|---|

| Control Chart Setup | Monitor stability | Real-time control charts, alerts |

| Process Window | Specify acceptable parameter ranges | Operator sheets, SOP |

| GR&R | Validate measurement system | GR&R report, measurement corrections |

Deliverables & Artifacts

FAI / PPAP Package

Drawing, dimensional report, material certificates, PSW and photographic evidence.

Capability Report

Cp/Cpk/Pp/Ppk calculations with charts and interpretation for CTQs.

Control Plan & PFMEA

Process flow, control methods, inspection plans and risk mitigation log.

SPC Templates & Dashboards

Sampling plans, control chart templates and recommended monitoring cadence.

Roles & Typical Sample Plans

Who Leads

Your program leader sets acceptance criteria; our process & quality engineers run builds, metrology and capability studies and compile the submission packages.

Typical Sample Sizes

FAI often uses 5–30 samples depending on complexity; capability studies use 30+ samples per CTQ for reliable Cpk estimation; Ppk/long‑term studies use larger samples over production runs.

Supplier Interaction

We coordinate directly with suppliers to collect evidence, witness runs and support corrective actions and revalidation if needed.

Typical Timeline Examples

| Activity | Representative SLA |

|---|---|

| Pre‑FAI planning | 1–3 business days |

| First article build & inspection | 3–14 days |

| Capability study (Cpk) | 2–4 weeks (depends on sample collection) |

| PPAP package compilation | 3–10 business days after data collection |

Case Snippet

A medical enclosure program required Cpk > 1.67 for a sealing face. Initial supplier runs showed Cpk = 1.1. We adjusted machining fixturing, optimized cutter strategy and tightened process windows. Requalification produced Cpk = 1.8 and PPAP approval within two pilot runs.

Tools & Reports

We deliver CMM reports, SPC exports (CSV/Excel), capability charts, control plans (PDF/Excel), and PPAP/FAI submission packages ready for customer review.