GD&T & Tolerance Optimization

📐 CMM‑Ready Drawings + Datum Strategy

📊 SPC / Cpk for CTQs 📑 PPAP / FAI Deliverables

Datum & Feature Control

Tolerance Stack-ups

Inspection & SPC Planning

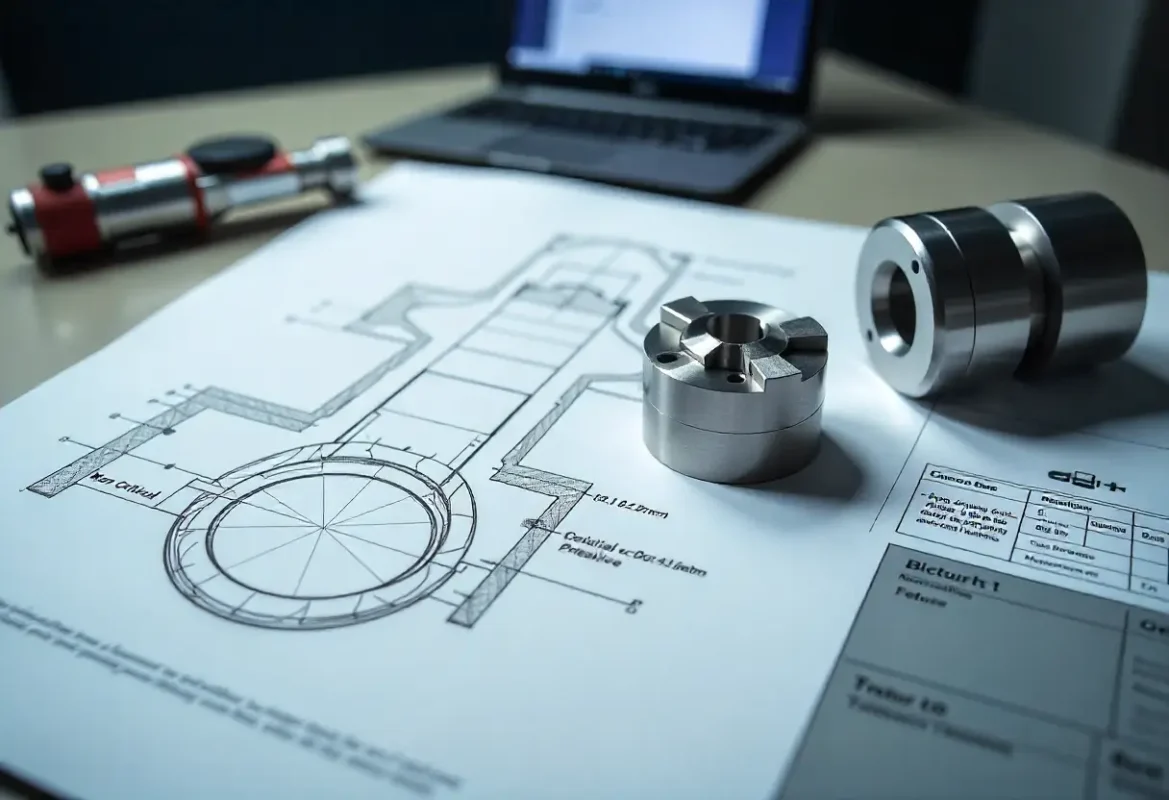

Why GD&T Matters

Datum Strategy & Feature Control

Define functional datums, primary/secondary/tertiary schemes and datum targets that reflect assembly methods and tooling references.

Tolerance Stack‑Ups & Gap Analysis

Statistical and worst‑case stack‑ups for mating features; identification of CTQs and sensitivity analysis for cost vs risk tradeoffs.

Inspection Planning & CMM Ready Outputs

CMM callouts, fixture gauges, sampling plans, GR&R considerations and SPC charting for critical characteristics.

From Tolerance Review To Production

Intake & Context

We capture assembly intent, mating features, tolerance drivers and functional requirements from drawings and CAD, including target volumes and allowable rework cost.

Datum & Stack‑Up Proposal

We propose a datum scheme and tolerance stack‑up aligned to assembly, tooling references and measurement strategy for the mating features.

Statistical Analysis

Run statistical and worst‑case analyses to determine feasible tolerances, sensitivity to CTQs and the cost impacts of tightening.

Inspection Plan

Create CMM plans, gauging concepts and sampling strategy; propose SPC/Cpk targets for CTQs to support production control.

Handover & Monitoring

Deliver drawings, inspection plan and SPC templates; support first article builds, GR&R and initial production monitoring to refine control limits.

Deliverables You Receive

GD&T Drawing Release

Datum scheme, feature controls, callouts and revision notes ready for supplier release

Tolerance Stack‑Up Report

Functional stack calculations, sensitivity analysis and recommended tolerance relaxations where possible

Inspection & SPC Pack

CMM callouts, sampling plan, SPC/Cpk targets and GR&R recommendations

How We Reduce Cost Without Risk

We identify non‑functional features that can be relaxed, propose consolidated datums to reduce measurement time, and balance tolerance tightening only where function requires it saving machining, inspection and scrap cost.

Typical Impact

Reduced inspection time, fewer ECO cycles, lower scrap and improved supplier throughput once control plans are established.

Tolerance Guidelines (Quick Reference)

General Dimension Tolerance

Flatness & Surface Controls

Geometric Tolerances

Supported File Types & Examples

| Item | Examples |

|---|---|

| CAD | SolidWorks, Creo, Inventor; STEP/IGES translations verified |

| Metrology | CMM routines, 3D scan exports, custom gauge drawings |

| SPC | Excel/CSV templates, Minitab-ready outputs |