Liquid Cooling Technology for High‑Power Electronics & EV Systems

We design and manufacture custom liquid cooling solutions—from cold plates and manifolds to complete liquid loops—engineered to manage high heat flux, tight space envelopes, and demanding reliability requirements.

📐 10+ Years Liquid Cooling Projects ♨️ FSW / Laser / Brazed Cold Plates

🏭 EVT → MP with PPAP & Cpk 🌎 Global Mfg + Dallas VMI / JIT Stock

EV Inverter & SiC Module Cooling

On‑Board & Off‑Board Chargers

Industrial Drives & Rectifiers

Why Partner with Us for Liquid Cooling

End‑to‑End Liquid Cooling Expertise

We work across the entire loop: cold plates, manifolds, hoses, fittings, pumps, and integration into your mechanical and electrical design.

- Single‑ and multi‑cold‑plate systems

- Series, parallel, and hybrid loop architectures

- Close collaboration with your mechanical & thermal teams

Optimized for High Heat Flux & Reliability

From IGBT / SiC modules to compact chargers, our designs are built to handle high power density and long‑term field conditions.

- Microchannel and pin‑fin geometries for high heat flux

- Low pressure drop designs for pump efficiency

- Corrosion‑resistant materials and coolant guidance

Designed for Production, Not Just Prototype

We align thermal performance with realistic manufacturing processes, tolerances, and quality controls suitable for automotive and industrial use.

- FSW, laser welding, brazing, and machining in‑house

- DFM / DFMA reviews and tolerance optimization

- PPAP / FAI / Cpk for critical flow and sealing features

How We Develop Your Liquid Cooling Solution

Our workflow takes you from requirements and architecture choices through CFD simulation, cold‑plate prototyping, loop validation, and stable mass production.

Requirements & Interfaces

Heat load, ambient conditions, duty cycle, space envelope, mounting interfaces, cost targets, and lifetime expectations.

Architecture & Layout

Single vs. multi‑plate loops, series or parallel branches, manifold strategy, inlet/outlet locations, and integration with pumps & fans.

Simulation & Optimization

3D CFD analysis of temperature, flow distribution, and pressure drop, plus DOEs on channel geometry, fin structures, and materials.

Prototyping & Validation

Rapid cold‑plate prototypes, loop builds, test rigs, and correlation of simulation to measured data before EVT / DVT / PVT and PPAP.

Download Liquid Cooling Design Checklist

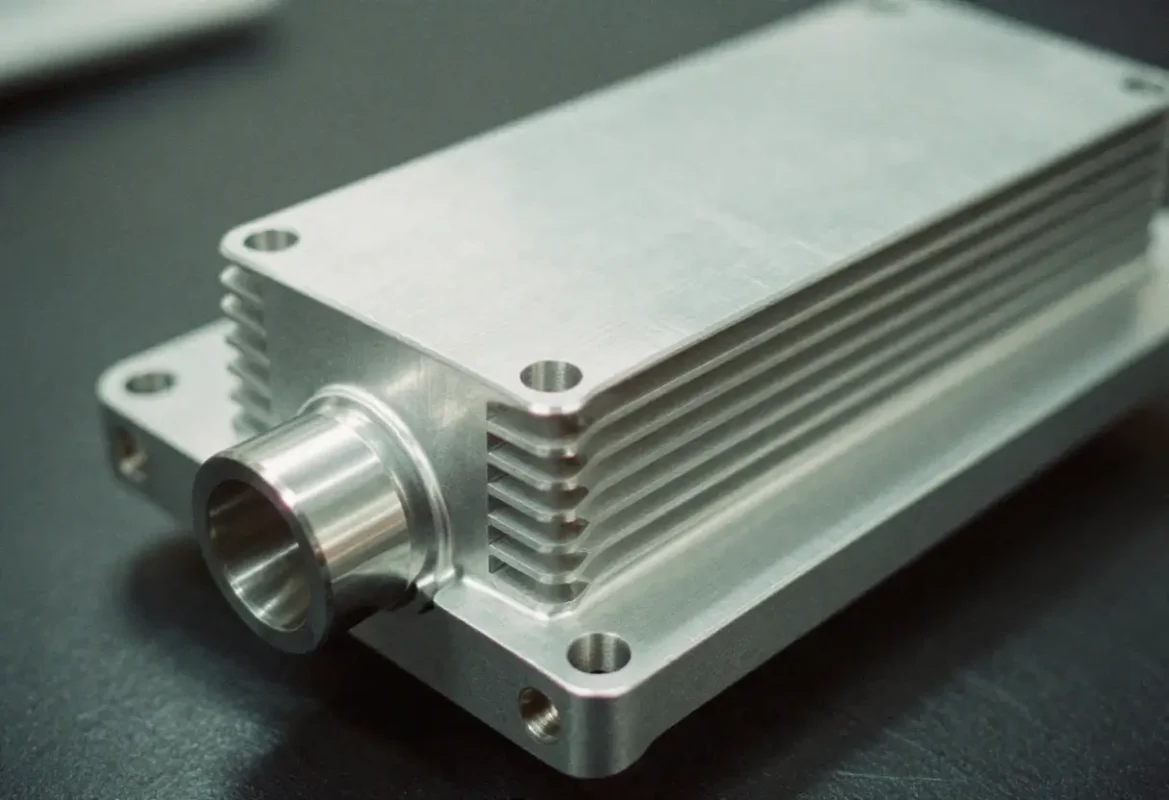

Cold Plate Technologies & Constructions

FSW (Friction Stir Welded) Cold Plates

Ideal for high reliability and automotive‑grade applications with strong, defect‑free joints and robust internal channels.

- High mechanical strength and leak resistance

- Suitable for long, continuous channels and manifolds

- Common in EV inverters and industrial drives

Laser‑Welded Cold Plates

Excellent for precise, localized joining with minimal distortion and flexible channel geometries in aluminum or stainless steel.

- High cleanliness and low‑distortion seams

- Compact, intricate channel layouts

- Well suited for chargers and compact power modules

Brazed & Bonded Cold Plates

Plate or fin cores joined by brazing or bonding to offer high surface area and strong thermal performance at scale.

- High surface area via internal fins or pin structures

- Good for high‑volume production runs

- Aluminum and copper configurations available

Internal Channel & Fin Options

| Geometry Type | Key Benefits | Typical Use Cases |

|---|---|---|

| Serpentine Channels | Simple, robust paths that are easy to manufacture and well‑suited for moderate heat flux. | General‑purpose electronics, industrial drives, and power modules where cost and robustness matter. |

| Microchannels | Very high heat transfer capability and tight temperature control, at the cost of higher pressure drop. | High power density IGBT / SiC modules, compact EV inverters, and space‑constrained systems. |

| Pin‑Fin / Turbulent Features | Increased turbulence and surface area for strong heat transfer with manageable pressure drop. | On‑board / off‑board chargers, rectifiers, and dense liquid‑cooled power electronics. |

Where Our Liquid Cooling Is Used

Automotive & EV

- Traction inverters and on‑board chargers

- DC/DC converters and auxiliary power modules

- Battery sub‑systems and power distribution units

Industrial & Power Electronics

- High‑power rectifiers and UPS systems

- Industrial drives and motion controllers

- Renewable and grid‑tied inverters

High‑Performance & Specialty Systems

- Test equipment and laboratory power supplies

- High‑performance computing and servers

- Custom OEM devices with extreme heat density

Beyond the Cold Plate: Complete Liquid Loops

Manifolds, Fittings & Hoses

Design and supply of manifolds, quick connects, hose assemblies, and mounting brackets tailored to your packaging and installation needs.

- Rigid and flexible manifold solutions

- Quick connectors, barbs, and threaded fittings

- Automotive‑grade hoses and clamps as required

Pumps, Fans & Reservoirs

Interface with your pump and fan strategy, or assist in selecting components to meet flow, noise, and lifetime targets.

- Support for single and multi‑pump architectures

- Optimization for pump head and NPSH margins

- Integration with reservoirs and degassing features

Assembly, Testing & Leak Control

Production processes and fixtures are designed to ensure leak‑free performance and repeatable assembly at scale.

- Helium, air‑under‑water, or pressure‑decay leak tests

- Dedicated jigs and fixtures for repeatable assembly

- Documentation and traceability for critical joints

Ready to Discuss Your Liquid Cooling Project?

Share your requirements, mechanical envelope, and power targets. Our team will review your design, suggest architecture options, and outline a clear path from prototype to mass production.

Upload Drawings for Liquid Cooling Review

Attach STEP/IGES/PDF files along with estimated heat load, coolant type, and desired temperature rise. Receive engineering feedback within 24 hours.

Schedule a Thermal Engineering Call

Book a 30–45 minute session with our engineers to review your constraints, simulate options, and discuss manufacturability and validation.

Request Sample Cold Plates

Evaluate our manufacturing quality and surface finishes with sample cold plates or coupon parts tailored to your program.