Heat Pipe & Vapor Chamber Integration for Compact, High‑Power Systems

📐 10+ Years Two‑Phase Cooling Design ⤴ Ultra‑Thin Vapor Chambers < 1 mm

🔁 3D Bends Custom Heat Pipe Geometries 🏭 EVT → MP With Reliability Validation

Compact Consumer & Gaming Devices

Vapor chambers and heat pipes integrated into slim chassis and heat spreaders for laptops, handhelds, and gaming devices.

LED & Professional Lighting

UAV / Optics & Specialized Systems

Custom‑shaped heat pipes and vapor chambers for UAV avionics, sensors, imaging, and other mission‑critical payloads.

Why Work with Us for Heat Pipes & Vapor Chambers

System‑Level Two‑Phase Architecture

We look at the entire thermal path—from die and package to spreaders, heat pipes, vapor chambers, and final sinks or housings.

- Hot‑spot and spreading resistance analysis

- Comparison of single vs. multi‑pipe and VC options

- Integration with structural parts and enclosures

Custom Geometry & Assembly Integration

Bend, flatten, and form heat pipes, or shape vapor chambers to match your mechanical envelope and mounting scheme.

- Flat, round, and custom cross‑sections

- 3D bending within defined radius limits

- Brazing, soldering, and mechanical fixation options

Built for Reliability & Volume Production

Two‑phase solutions are validated and documented so they can be produced consistently over long lifecycles.

- Material and working fluid compatibility selection

- Leak, burst, and cycling tests for critical programs

- Process control, Cpk, and visual/aesthetic standards

How We Design Your Heat Pipe & Vapor Chamber Solution

Our workflow connects application requirements, thermal modeling, mechanical integration, and reliability testing into a single, repeatable process.Application & Constraints

Define power map, hot‑spot locations, allowable temperatures, gravity orientation, envelope, mounting, and shock/vibration conditions.

Architecture & Geometry

Select between heat pipes, vapor chambers, or hybrids. Define dimensions, thickness, routing, and interface surfaces to sinks and housings.

Simulation & Design Refinement

Thermal modeling of spreading resistance, evaporator and condenser performance, and transient response, followed by geometric tuning and interface optimization.

Prototyping, Testing

Build prototypes, validate cooling performance and mechanical robustness, then lock specifications, fixtures, and QC plans for volume production.

Heat Pipe & Vapor Chamber Technologies

We offer a range of heat pipe and vapor chamber constructions, wick structures, and working fluids, matched to your orientation, thermal load, and lifecycle needs.

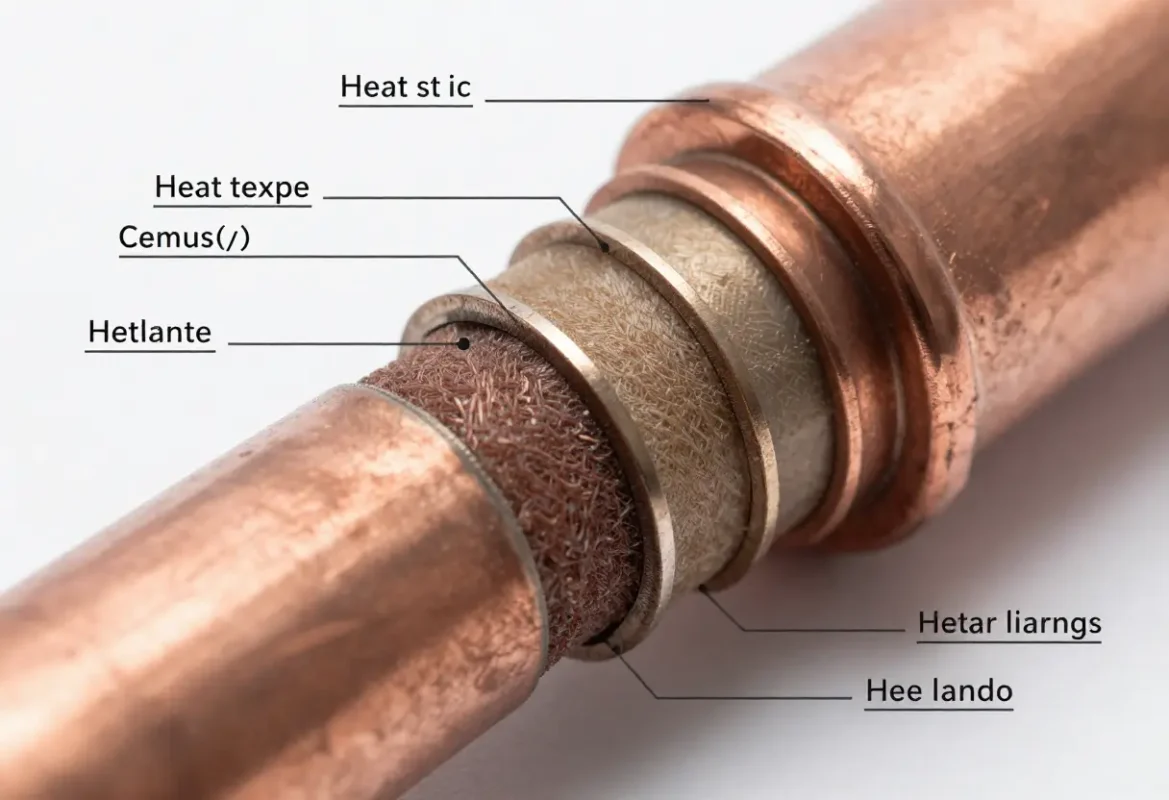

Heat Pipes

Copper or aluminum heat pipes in round or flattened formats, routed in 2D or 3D to move heat from hot spots to remote sinks or fins.

- Standard diameters with custom lengths and bends

- Flattened sections for low z‑height interfaces

- Single‑ended or multi‑contact evaporator/condenser zones

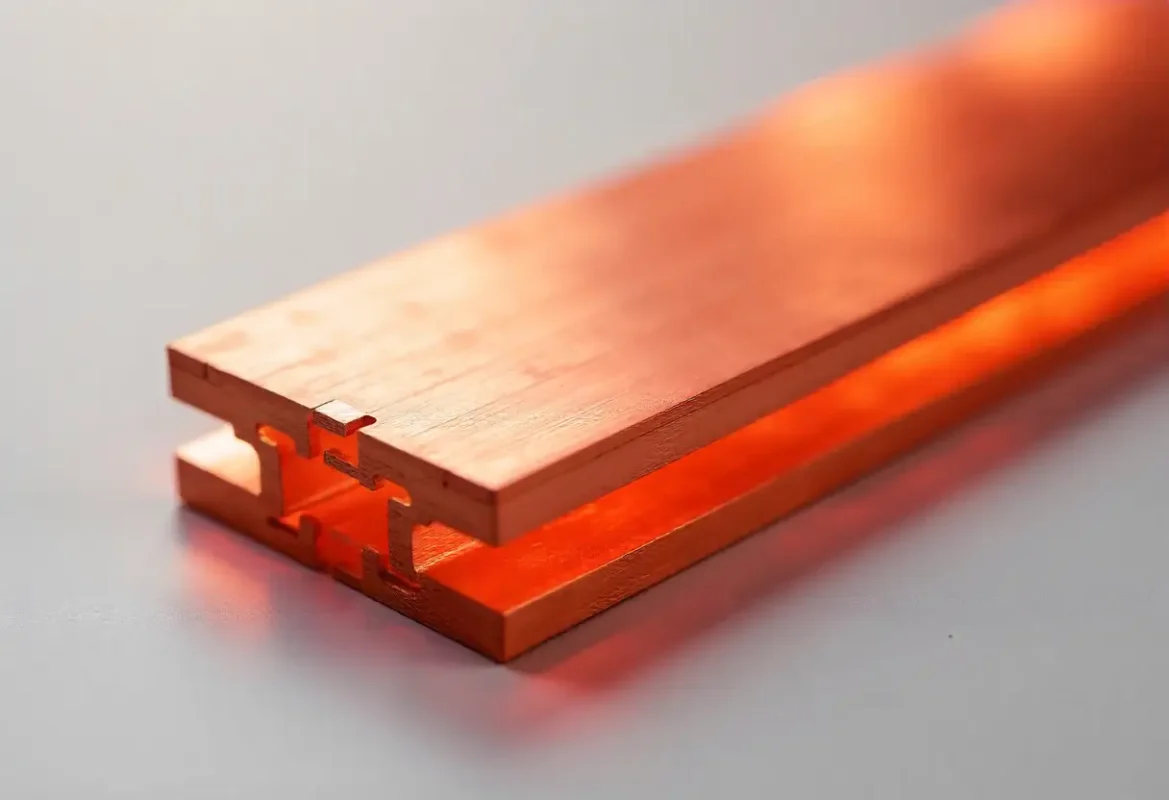

Vapor Chambers

Planar two‑phase devices that spread heat in X‑Y while maintaining minimal thickness, ideal for slim, high‑power assemblies.

- Ultra‑thin designs down to sub‑millimeter levels

- Single‑layer or multi‑cavity constructions

- Support for cut‑outs, holes, and formed edges

Wick Structures & Working Fluids

We select wick and fluid combinations that deliver reliable performance across your orientation and operating temperature range.

- Grooved, sintered, mesh, and composite wicks

- Orientation‑tolerant designs for mobile and UAV systems

- Fluid choices matched to temperature and material set

Typical Design Parameters We Optimize

| Parameter | Example Considerations | Impact on Design |

|---|---|---|

| Heat Load & Hot‑Spot Size | Peak vs. steady‑state power, hot‑spot footprint, and allowable temperature rise (ΔT). | Defines evaporator area, wick structure, and overall device dimensions. |

| Orientation & Gravity | Upright, inverted, rotating, or random orientation during service and transport. | Influences wick selection, fluid charge, and allowable tilt angles for reliable return flow. |

| Envelope & Interfaces | Maximum thickness, required bends, mounting points, keep‑out zones, and contact surfaces. | Drives choice of heat pipe vs. vapor chamber, routing strategy, and geometric layout. |

| Environment & Reliability | Shock, vibration, humidity, contamination risk, and thermal cycling profile in the field. | Impacts material pairings, mechanical reinforcement, and validation / test strategy. |

Validating Two‑Phase Solutions for the Real World

Every thermal design is backed by structured testing and documentation so you can qualify us as a long‑term partner for safety‑ and mission‑critical applications.

Thermal Performance Testing

Characterization of thermal resistance and spreading performance Transient response and warm‑up / cool‑down profiling Performance across different orientations and loads

Mechanical & Environmental Testing

Vibration and shock testing for automotive / industrial profiles Thermal cycling and humidity exposure where applicable Drop and handling tests for portable devices

Quality & Documentation

Specification sheets and drawings with controlled tolerances Process documentation, control plans, and inspection criteria Traceability and change control over the product lifecycle

Applications for Heat Pipe & Vapor Chamber Integration

Consumer Electronics & Gaming

- Laptops, tablets, and handheld gaming devices

- Game consoles and high‑performance compute modules

- Thermal modules for custom gaming and lightsaber projects

LED, Optics & Imaging

- High‑power LED light engines and fixtures

- Optical blocks and camera systems requiring stable temperature

- Gimbals, sensors, and vision systems on UAVs and robots

Industrial & Specialized Systems

- Space‑constrained industrial controllers

- Ruggedized computing and edge devices

- Custom OEM equipment with challenging form factors