Thermal Performance Testing for Real‑World Reliability

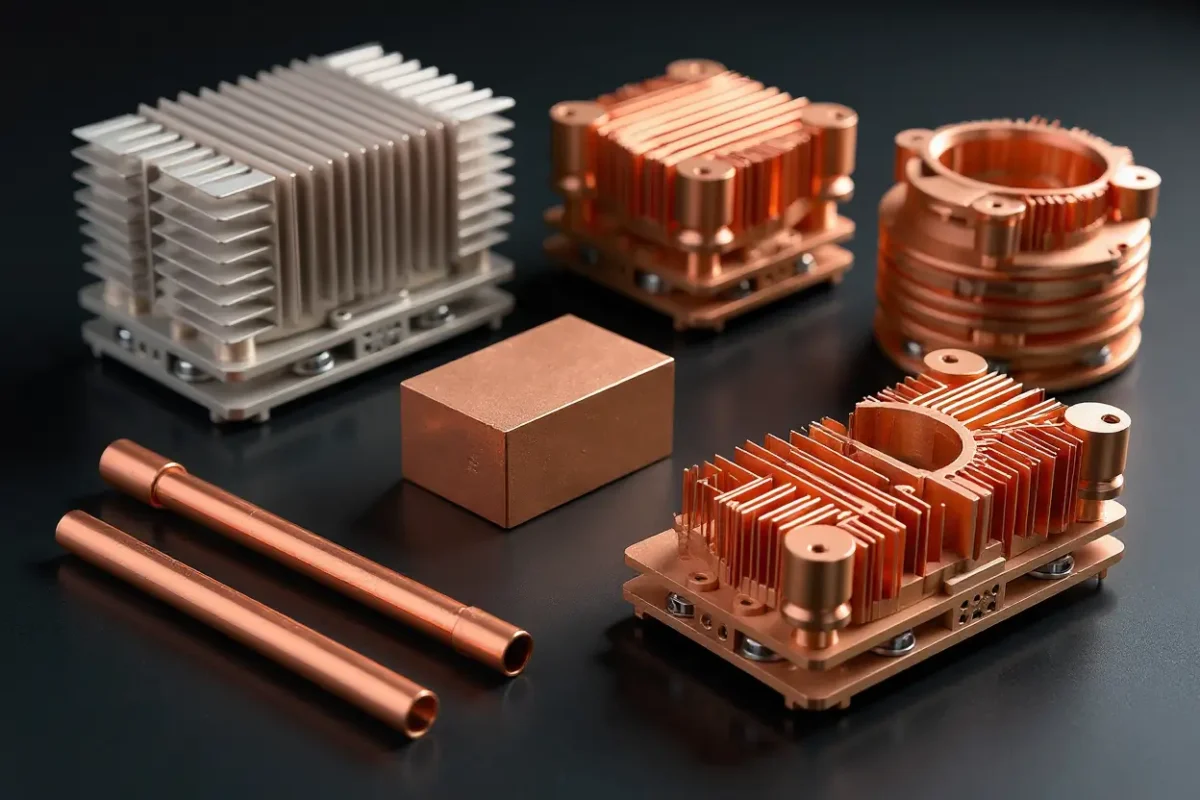

We validate the performance of your cold plates, heat sinks, heat pipes, and vapor chambers under realistic power, flow, and environmental conditions—so your thermal design works not only in simulation, but in the field.

📊 Steady‑State Thermal Characterization 🌡️ ΔT & θ Thermal Resistance (°C/W)

💧 Flow / ΔP Liquid System Curves 🔁 EVT → PPAP Data‑Driven Validation

Cold Plate Bench Testing

Heat Sink & Module Characterization

Correlation to Simulation & Specs

Why Thermal Performance Testing Matters

Close the Loop with Design & Simulation

Our thermal testing is built to validate assumptions from your CFD models and design targets—not just generate numbers.

- Test setups aligned with your boundary conditions

- Correlation back to simulation and datasheets

- Iteration support for design and process changes

Reduce Risk Before EVT / DVT / PVT

Identify thermal risks before you commit to tooling, costly redesigns, or large qualification lots.

- Pre‑EVT functional and stress tests

- Thermal margin assessment and derating

- Support for PPAP and customer qualification plans

Documented, Repeatable, Scalable

Standardized procedures and fixtures allow results to be repeated across builds and over the life of the program.

- Standardized test instructions and checklists

- Calibrated sensors and controlled environments

- Traceable records for audits and future builds

What We Test

Cold Plates & Liquid Loops

- Aluminum and copper cold plates (FSW, laser, brazed)

- Microchannel, serpentine, and pin‑fin internal geometries

- Complete loops with pumps, hoses, manifolds, and reservoirs

Heat Sinks, Pipes & Vapor Chambers

- Skived, extruded, and bonded‑fin heat sinks

- Heat pipe and vapor chamber modules

- Hybrid air/liquid systems and integrated thermal modules

System‑Level Assemblies

- Power electronics inverters, rectifiers, and chargers

- Robotics, UAV, and industrial controllers

- Consumer, gaming, and LED lighting systems

How We Test Thermal Performance

From steady‑state and transient tests to flow and pressure mapping, we build test plans that match how your product will actually be used.

Steady‑State & Transient Thermal Tests

- Controlled power input to emulate real load profiles

- Measurement of temperature rise and thermal resistance (°C/W)

- Step response and transient behavior under changing loads

- Testing at different ambient temperatures and airflow rates

Flow & Pressure Characterization

- Flow vs. pressure (ΔP) curves for liquid cooling systems

- Verification of minimum and maximum flow limits

- Assessment of pump head, NPSH margins, and cavitation risk

- Support for sizing and selection of pumps and valves

Interface & Contact Resistance Evaluation

- Impact of TIM selection, thickness, and installation method

- Clamp force and flatness influences on junction‑to‑plate resistance

- Comparisons of interface stacks (e.g., bare metal vs. pad vs. grease)

Environmental & Use‑Case Testing

- Operation across specified temperature and humidity ranges

- Thermal performance with varying airflow, orientation, or blockage

- Combined tests with mechanical vibration or power cycling

Typical Applications for Our Liquid Cooling

Our liquid cooling solutions are deployed across automotive & EV, power electronics, industrial automation, and high‑performance systems.

Automotive & EV

- Traction inverters and on‑board chargers

- DC/DC converters and auxiliary power modules

- Battery sub‑systems and power distribution units

Industrial & Power Electronics

- High‑power rectifiers and UPS systems

- Industrial drives and motion controllers

- Renewable energy and grid‑tied inverters

High‑Performance & Specialty Systems

- Test equipment and laboratory power supplies

- High‑performance computing and servers

- Custom OEM devices with extreme heat density

Ready to Optimize Your Thermal Design?

Share your thermal challenge and our engineering team will review your requirements, suggest architecture options, and outline a clear path from prototype to mass production.

Upload Drawings for Liquid Cooling Review

Attach STEP/IGES/PDF files along with estimated heat load, coolant type, and desired temperature rise. Receive engineering feedback within 24 hours.