Custom Mechanical Manufacturing Solutions for High‑Performance Products

🛠️ Multi‑Process CNC, Molding 📈 Prototype → MP (EVT / DVT / PVT)

📊 DFM / DFMA Cost Optimization 🏭 Global Mfg + Dallas VMI / JIT Stock

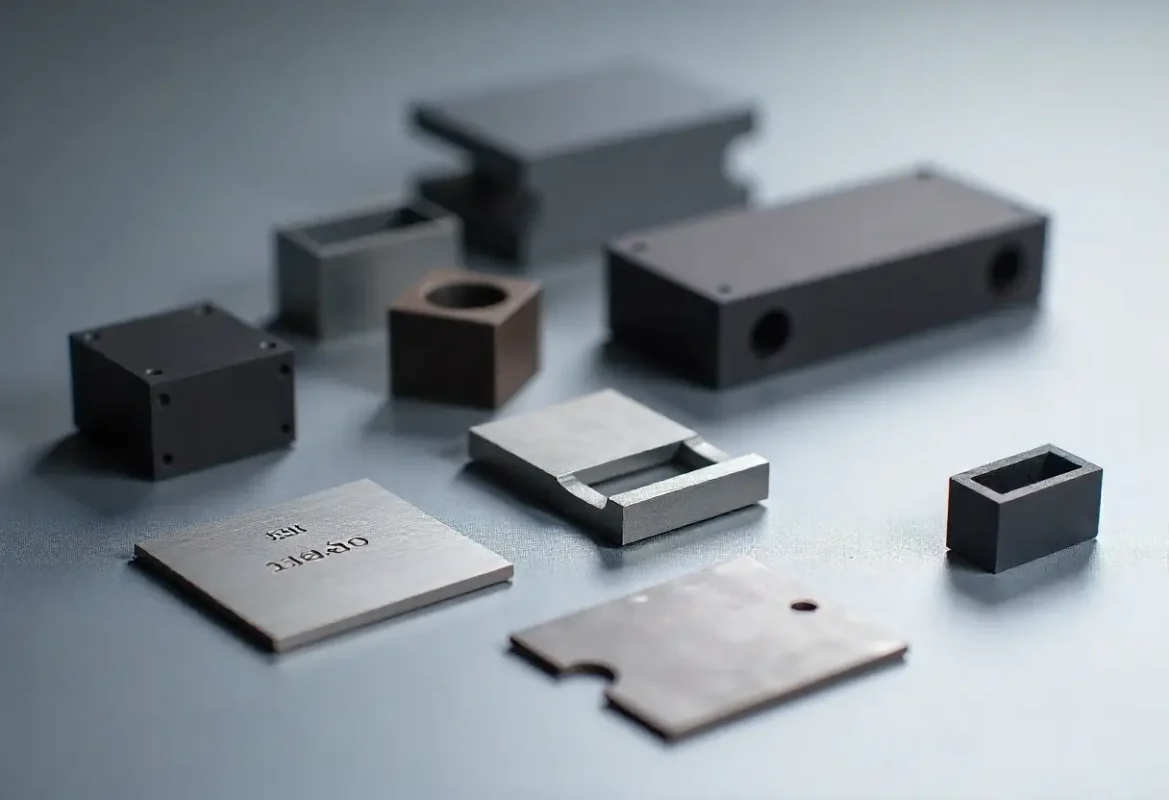

Precision CNC & Enclosures

Molded & Cast Mechanical Components

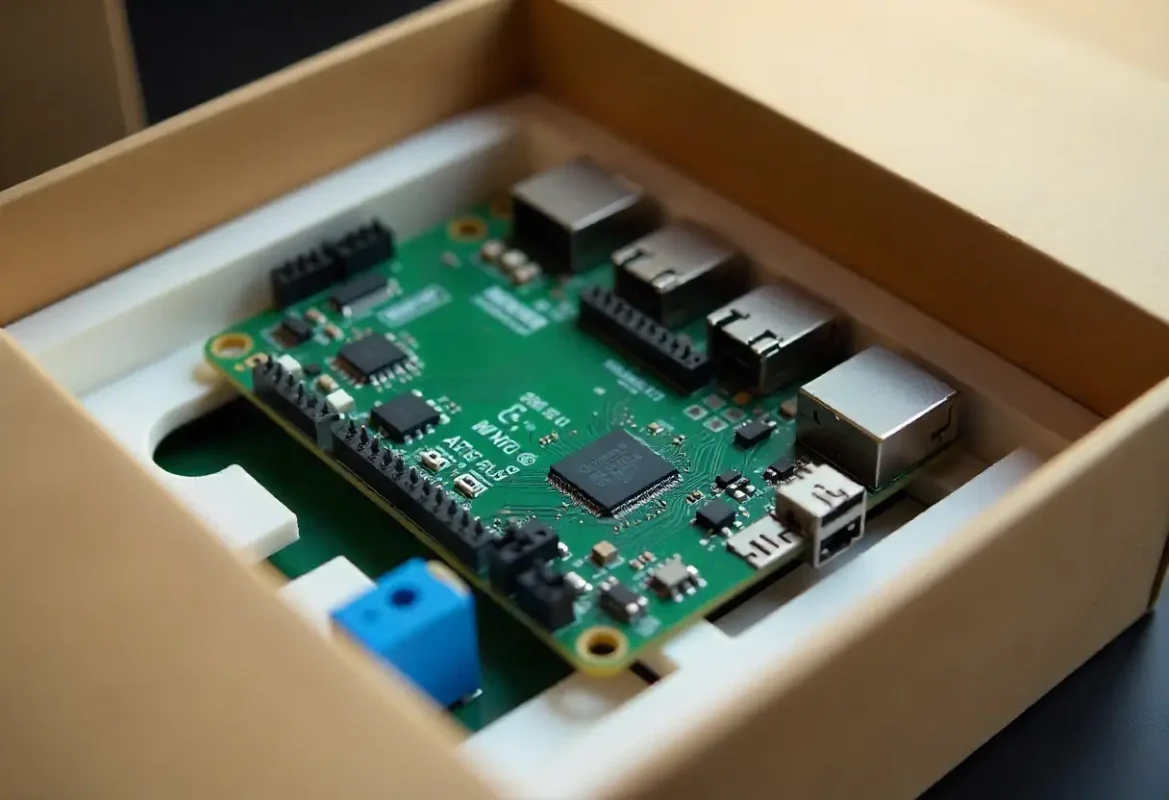

Assemblies & Integrated Modules

Why Choose Our Custom Mechanical Manufacturing Solutions

Multi‑Process Capability Under One Roof

We cover the core processes you need for modern mechanical systems, reducing interfaces and hand‑offs between different vendors.

- CNC machining (metal & plastic) for precision features

- Injection molding, die casting, and extrusion for volume parts

- Sheet metal, stamping, deep draw, and welding for structures

Engineering‑Driven, Not Just Part‑Driven

Our engineers work directly with your designers to align requirements, tolerances, finishes, and cost targets before parts hit the shop floor.

- DFM / DFMA reviews and cost‑down proposals

- Material and process trade‑off studies

- Support for GD&T, stack‑up, and tolerance optimization

Built for Programs, Not One‑Off Jobs

We support you from early prototypes through ramp‑up and long‑term mass production, with documentation and quality systems to match.

- Prototype & EVT support with fast-turn builds

- DVT / PVT builds with process tuning and Cpk

- PPAP, control plans, and ongoing quality monitoring

From Concept to Stable Mass Production

Our workflow takes your mechanical design from CAD to qualified, repeatable production, with clear hand‑offs at each stage.Requirements & DFM Review

- Review drawings, 3D models, and functional requirements

- Identify risk areas, tolerance traps, and cost drivers

- Propose design & process changes where beneficial

Prototyping & EVT Builds

- Rapid parts via CNC, soft tooling, or bridge tooling

- Assembly trials and functional fit checks

- Initial measurement reports and feedback to design

Prototyping & EVT Builds

- Tooling tuning and process parameter optimization

- FAI, capability studies, and initial Cpk data

- Refinement of assembly jigs and work instructions

Mass Production & Lifecycle Support

- Stable production with defined control plans

- Continuous improvement and cost‑down opportunities

- Dallas warehouse, VMI / JIT and after‑sales support

Core Mechanical Manufacturing Capabilities

CNC Machining (Metal & Plastic)

- 3‑, 4‑, and 5‑axis milling and turning

- High‑tolerance features and tight GD&T requirements

- Complex housings, brackets, and precision components

Molding, Casting & Extrusion

- Injection molding for engineering plastics

- Die casting for aluminum and zinc components

- Aluminum, rubber, and silicone extrusion profiles

Sheet Metal & Fabrication

- Stamping, deep draw, and progressive dies

- Laser cutting, bending, and forming

- Welding (TIG, MIG, laser) and mechanical assembly

Rubber & Silicone Components

- Compression, transfer, and LSR molding

- Seals, gaskets, overmolds, and vibration isolators

- Material selection for temperature and chemical resistance

Surface Finishing & Coatings

- Anodizing, hard anodizing, and color anodizing

- Powder coating, painting, and plating

- Brushing, blasting, polishing, and laser marking

Assembly & Integrated Modules

- Mechanical and electromechanical assemblies

- Fastener, seal, and insert installation

- Functional tests and packaging for shipment

Typical Design Parameters We Optimize

| Requirement Area | What We Review | How We Add Value |

|---|---|---|

| Geometry & Tolerances | Critical dimensions, GD&T, and stack‑ups across parts and assemblies. | Identify over‑tight tolerances and propose cost‑effective alternatives while maintaining function. |

| Material & Process Choice | Selected alloys, plastics, rubbers, and intended manufacturing routes. | Recommend alternate materials or processes to improve cost, lead time, manufacturability, or performance. |

| Surface & Cosmetic Requirements | Ra, color, gloss, texture, branding, and visible‑surface expectations. | Align cosmetic standards with realistic finishing options and inspection criteria to avoid rejects. |

| Assembly & Service | Fastening, sealing approaches, access clearances, and assembly sequence. | Design for easier assembly, fewer tools, and better field serviceability and reliability. |

Quality, Documentation & Supply Chain Integration

Quality & Documentation

ISO 9001 quality management framework FAI, PPAP, Cpk studies, and control plans for key features Inspection reports, CoCs, and material traceability

Supply Chain & Logistics

EXW, FOB, CIF, and DDP shipping options Dallas warehouse with VMI / JIT programs Packaging engineering for safe and efficient transport

Where Our Custom Mechanical Solutions Are Used

Automotive, EV & Mobility

- Structural brackets, housings, and covers

- Custom enclosures for inverters, chargers, and controllers

- Aftermarket and motorsport upgrade components

Robotics, UAV & Industrial

- Robot frames, joints, and mounting hardware

- Precision machined parts for motion systems

- Lightweight structures for UAVs and automated equipment

Medical, Outdoor & Specialty Devices

- Medical and laboratory equipment components

- Outdoor, sporting, fishing, and tactical products

- Consumer and audio/photography hardware housings

Ready to Build Your Next Mechanical System?

Upload Drawings for Manufacturing Review

Attach STEP/IGES/PDF files and basic requirements. Receive engineering feedback and a quote outline within 24 hours.