Thermal Solutions for High‑Power, High‑Reliability Systems

📐 10+ Years Thermal Engineering ♨️ Liquid & Two‑Phase Cooling Expertise

🔁 EVT / DVT / PVT → MP (PPAP & Cpk) 🏭 Global Manufacturing + Dallas Warehouse

EV Inverter & SiC Module Cooling

High‑Power Rectifier Cold Plates

Compact Vapor Chamber Solutions

Why Leading Innovators Trust Our Thermal Solutions

We combine deep thermal engineering, multi‑process manufacturing, and global logistics to deliver cooling systems that work in the real world—at scale.

Deep Thermal Engineering Expertise

A dedicated team focused on liquid cooling, heat pipes, and vapor chambers for demanding electronics, EV, and industrial applications.

- System‑level thermal architecture and trade‑off studies

- CFD simulation of temperature, flow, and pressure drop

- Optimization for performance, reliability, and cost

Design‑for‑Manufacturing from Day One

We design cooling hardware for real manufacturing processes and long‑term production stability—not one‑off prototypes.

- DFM / DFMA on plates, manifolds, modules, and enclosures

- EVT / DVT / PVT support with rapid iteration loops

- PPAP / FAI / Cpk and process windows for volume builds

Integrated Manufacturing & Global Fulfillment

Thermal components and assemblies are built where they are engineered, then deployed globally with local support.

- CNC, die casting, extrusion, brazing, welding, and assembly

- Packaging engineering, ISTA/drop testing, and DDP options

- U.S. Dallas warehouse for VMI / JIT and after‑sales support

From Requirements to a Validated Thermal System

We guide you from initial power and temperature targets through simulation, prototyping, qualification, and stable mass production—so you can launch with confidence.Requirements & Constraints

Heat load, ambient conditions, duty cycle, space envelope, mounting interfaces, cost targets, and lifetime expectations.

Concept & Architecture

Selection of liquid vs. air vs. two‑phase; cold plate, heat pipe, or vapor chamber configuration and integration with mechanics and PCBs.

Simulation & Optimization

3D thermal and CFD analysis, flow distribution and pressure drop studies, and DOEs on channels, fins, and materials.

Prototyping & Testing

Rapid cold plate, heat sink, and module builds with bench testing, sensor instrumentation, and data‑driven refinement.

Qualification & Production

EVT / DVT / PVT builds, reliability and environmental testing, and PPAP / FAI / Cpk with defined process windows for mass production.

Download Thermal Design & Validation Flow

Thermal Technologies We Specialize In

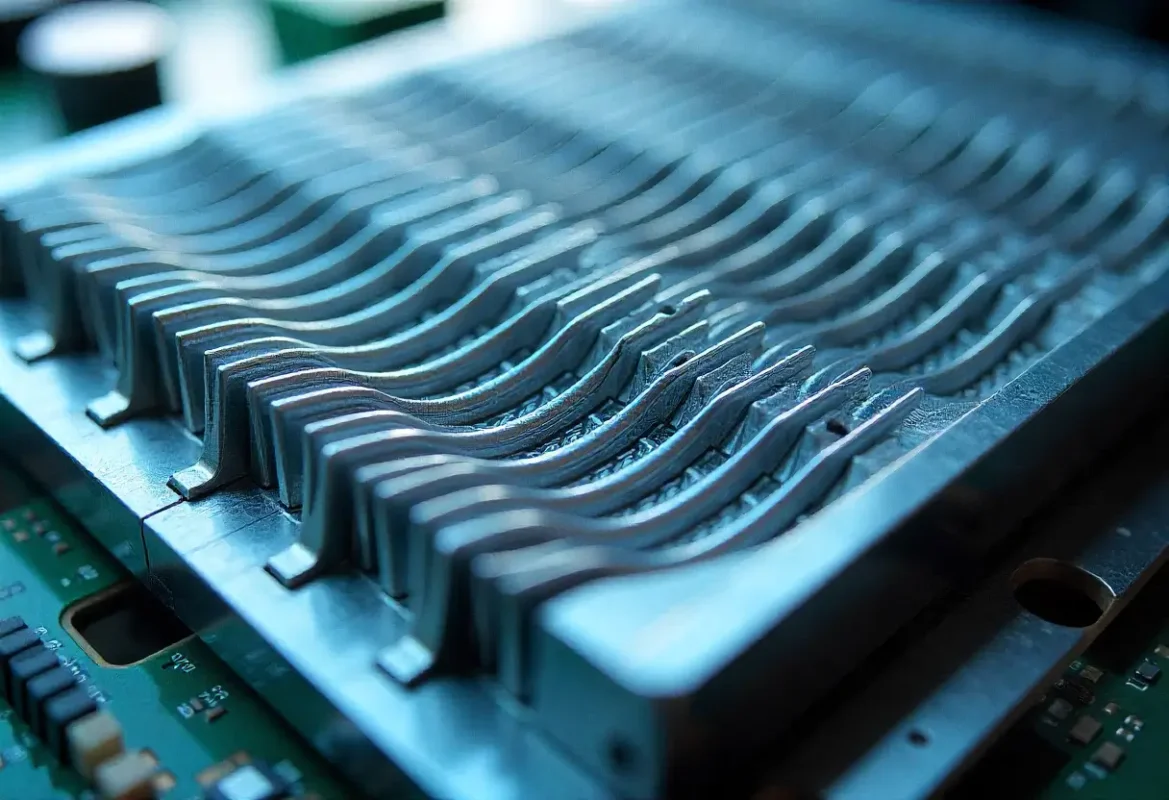

Liquid Cooling & Cold Plates

Custom aluminum and copper cold plates using FSW, laser welding, and brazing with microchannel, serpentine, and pin‑fin designs.

- EV inverter & SiC / IGBT module cooling

- On‑board & off‑board charger cold plates

- High‑power rectifiers & industrial drives

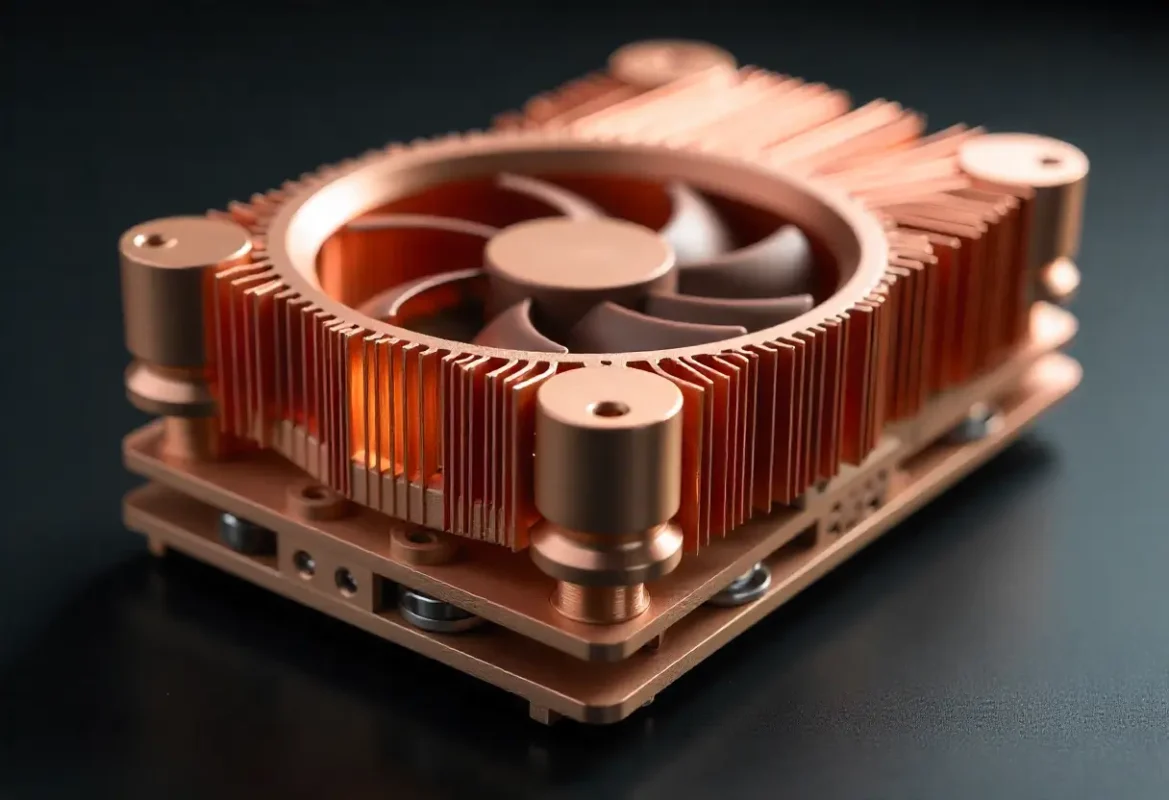

Heat Pipes & Vapor Chambers

Two‑phase cooling in compact geometries with flat and round heat pipes, ultra‑thin vapor chambers, and custom shapes.

- Gaming and high‑performance consumer devices

- LED and professional lighting systems

- UAV / aerospace electronics and optics

High‑Performance Heat Sinks

Skived, extruded, bonded‑fin, and machined heat sinks tuned for natural or forced convection with robust surface finishes.

- Aluminum and copper skived solutions

- Ducted and open‑air configurations

- Fan, blower, and shroud integration

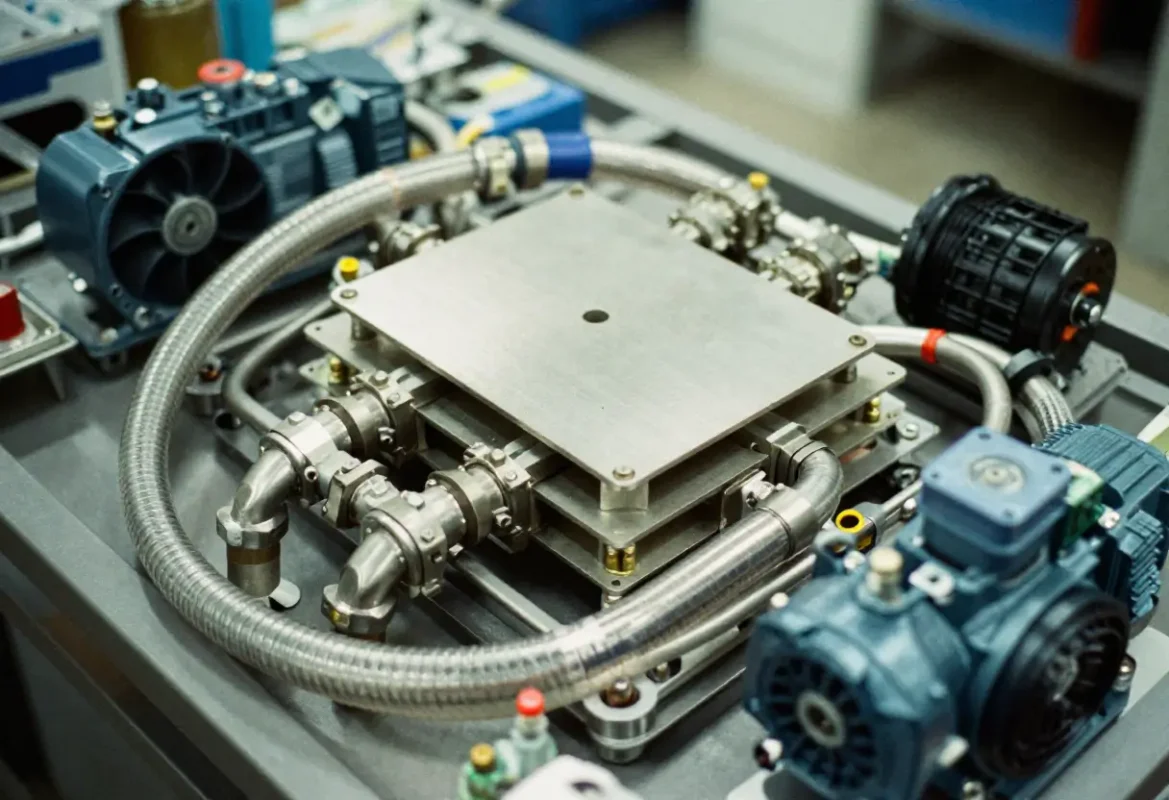

Integrated Thermal Modules

Complete thermal sub‑systems including cold plates, manifolds, hoses, fans/pumps, housings, and sensors, fully assembled and tested.

- Liquid loops & manifolds

- Fan sink and blower modules

- Thermal modules within enclosures

Where Our Thermal Solutions Are Deployed

We combine deep thermal engineering, multi‑process manufacturing, and global logistics to deliver cooling systems that work in the real world—at scale.

Automotive & EV / Motorsport

Inverter and power module cooling (IGBT / SiC) On‑board & off‑board EV charger cold plates Battery sub‑system and DC busbar cooling

Robotics, Automation & UAV

Servo drive and motion controller cooling Motor and actuator thermal management UAV payload and avionics cooling

Consumer & Specialty Devices

Gaming and high‑performance computing Professional lighting & photography equipment Specialty devices such as lightsabers & tactical gear

Power Electronics & Energy

High‑power rectifiers and power supplies Industrial drives and motion control Renewable and grid‑tied power modules

Medical & Laboratory Systems

Imaging and diagnostic equipment Analytical instruments and laser systems Temperature‑critical subsystems and optics

Custom OEM Projects (NDA)

Confidential program support under NDA Joint development with your engineering teams Long‑term production and lifecycle management

How We Validate Your Thermal Solution

Thermal Performance Testing

Steady‑state and transient thermal characterization Temperature rise, ΔT, and thermal resistance (°C/W) Flow rate and pressure drop measurement for liquid systems

Mechanical & Environmental Testing

Vibration and shock for automotive and industrial standards Thermal cycling, humidity, and salt spray (when required) Long‑term aging and reliability stress testing

Documentation & Quality

FAI / PPAP / Cpk on critical dimensions and features PFMEA, control plans, and traceability for key components Compliance with relevant AQL / IPC / MIL / ASTM standards

Why Choose Us for Thermal, Not Just Any Parts Supplier

We combine deep thermal engineering, multi‑process manufacturing, and global logistics to deliver cooling systems that work in the real world—at scale.

Thermal‑First, Not Price‑First

We begin with performance, reliability, and safety margins, then optimize for cost through design and process, avoiding downstream redesigns.

Aligned Thermal, Mechanical & Manufacturing

Thermal engineers and manufacturing engineers collaborate from day one to ensure your design runs robustly in serial production.

Proven in Demanding Applications

Solutions deployed in EV, power electronics, robotics, UAV, and medical systems—with many programs executed under NDA.

Speed with Engineering Discipline

24‑hour engineering feedback, rapid prototypes, and structured EVT / DVT / PVT builds supported by clear documentation.

Global Manufacturing, Local Support

China‑based production with Dallas warehouse, VMI / JIT programs, and responsive after‑sales for U.S. and global customers.

Integrated Supply Chain Perspective

Packaging, logistics, and inventory strategy are built into the engineering process to simplify your overall program.

Ready to Optimize Your Thermal Design?

Share your thermal challenge and our engineering team will review your requirements, suggest architecture options, and outline a clear path from prototype to mass production.