Request a quote for metal binder jet parts—an efficient option for complex geometry, prototypes, and cost-sensitive production runs. Availability depends on material system, geometry, and finishing requirements.

STEP | STP | SLDPRT | STL | DXF | IPT | 3MF | 3DXML | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

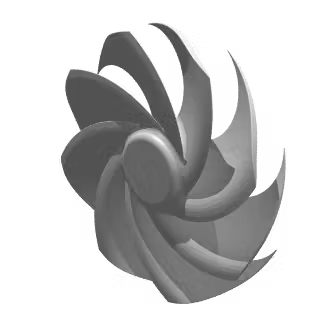

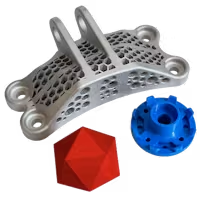

Metal binder jetting is a metal 3D printing process used to produce complex parts without laser-melting each layer. It’s often selected for programs that need a cost-effective path to metal parts, especially when geometry is complex and production volumes are moderate.

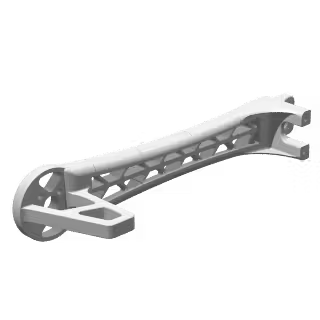

Binder jetting machines can offer high throughput and large build areas (machine-dependent), making the process attractive for low-to-medium batch production, fixtures, and prototypes. Final properties and dimensional results depend on the material system and the sintering/infiltration route used.

General tolerances depend on geometry, support strategy (powder support), sintering behavior, and wall thickness. Parts with thicker sections, large flat faces, or uneven wall thickness can be more prone to distortion or dimensional shift. Improved tolerances may be possible with post-processing (such as machining) or after a successful prototype build and measurement review (case-by-case).

For critical dimensions, include a 2D drawing with explicit tolerances and identify critical datums and mating surfaces.

Our quick reference guides let you quickly compare different 3D printing processes!

Metal binder jetting builds parts from a CAD file using a multi-step additive process:

Printing (“green” part creation)

A binder is selectively deposited into a metal powder bed layer by layer, creating a bound powder shape.

Curing

The printed “green” part is cured to stabilize the shape for handling.

Densification (sinter and/or infiltration)

The part is densified in a furnace. Depending on the material system, the part may sinter and/or be infiltrated (for example, with bronze) to improve density and strength.

Because parts are supported by surrounding powder during printing, support structures may be reduced or eliminated. However, dimensional change during furnace processing is expected. Engineers should design with binder jet shrinkage and feature survivability in mind, especially for thin walls, small holes, and tight fits.

Material availability depends on the supplier route and program requirements. If you need a specific alloy or specification, include it in your RFQ notes so we can review feasibility.

(If you want this page to match your current wording, tell me whether you truly offer “420i/316i-style” systems; otherwise I’ll generalize this section safely.)

Binder jet parts can have a distinctive surface appearance and may show color variation depending on the material system and finishing route. Finishing can enhance brightness, smoothness, or the overall visual tone.

Standard finish (example):

A bead-blast style finish that creates a matte metallic appearance.

Additional finish options (project-dependent):

Media blasting, vibratory finishing, polishing, patina-like finishes, or other cosmetic treatments.

A bright, matte metallic finish created by bead blasting (finish route dependent).

Smoother appearance with reduced texture on exposed surfaces (geometry dependent).

A darker, aged metallic aesthetic.

Patterned aesthetic finish option (appearance depends on part geometry and finishing route).

Warm bronze-toned aesthetic.

Copper-like tone and appearance.

Binder jetting requires design-for-manufacturing considerations due to shrink and sintering behavior.

General guidelines (high level):

Link text: View the Binder Jetting Design Guide

Strong metal parts for fixtures, jigs, and tooling where cost and speed matter.

Functional prototypes that benefit from metal strength and complex geometry.

A practical option for repeat runs when the design is stable and the process route meets mechanical and dimensional needs (project-dependent).

Free shipping available for domestic 3D printing orders ; learn more!

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential