Upload your CAD files to request a quote for metal prototypes and production parts using DMLS/SLM (laser powder bed fusion). DMLS is a strong choice when you need complex geometry, high density, and durable metal performance without hard tooling.

STEP | STP | SLDPRT | STL | DXF | IPT | 3MF | 3DXML | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

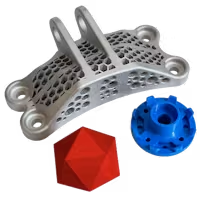

Direct metal laser sintering (DMLS)—often grouped with selective laser melting (SLM)—is a metal 3D printing technology used to produce metal parts with strong mechanical performance and detailed geometry. Because the process builds parts from powder without dedicated mold tooling, it’s well suited for prototypes, low-to-mid volume production, and parts that benefit from additive-only features like internal channels, lattice structures, and topology-optimized shapes.

DMLS can also reduce assembly complexity by consolidating multiple components into a single printed part, which can improve reliability and reduce weight by eliminating fasteners and joints (application-dependent).

LK Tools supports DMLS projects by reviewing geometry, material requirements, and post-processing needs during quoting so the printed part matches functional expectations.

General capability and tolerances depend on build stresses, support strategy, orientation, and geometry. Flat, broad surfaces, uneven wall thickness, and thicker sections may be more prone to deviation or warp. Tighter or more controlled tolerances may be possible with post-processing (such as machining) or after a successful prototype build and review (case-by-case).

For critical features, include a 2D drawing with explicit tolerances, datums, and inspection requirements.

Our quick reference guides let you quickly compare different 3D printing processes!

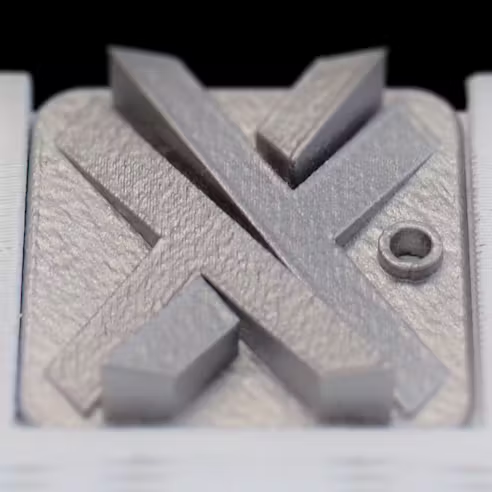

DMLS builds parts directly from a CAD file by selectively fusing thin layers of metal powder using a laser. Each new layer of powder is spread across the build area, and the laser fuses the cross-section for that layer. This repeats layer-by-layer until the part is complete.

Because DMLS builds parts additively, it can produce:

After printing, parts typically require depowdering and support removal, and may also require heat treatment, surface finishing, and machining depending on application needs.

DMLS supports multiple metal alloys. Availability depends on machine configuration, geometry, and program requirements. If you need a specific alloy or specification, include it in your RFQ notes.

(If you provide your exact alloy list—e.g., AlSi10Mg, 17-4PH, 316L, Ti64, Inconel, tool steels—I’ll format this section into a clean list like the other pages.)

Standard

Support removal plus media blasting (or similar standard post-processing) to provide a uniform surface appearance.

Custom

Additional post-processing options—such as CNC machining of critical features, polishing, or specialty finishing—may be available upon request (case-by-case).

Strong metal prints for jigs, fixtures, and tooling components—especially where complex geometry or weight reduction helps.

Functional metal prototypes for fit, performance testing, and design validation without hard tooling.

Durable end-use parts for programs that benefit from additive geometry or don’t justify casting/forging tooling (project-dependent).

Free shipping available for domestic 3D printing orders ; learn more!

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential