Durable powder coating for corrosion resistance and long-lasting color on metal parts. Service availability depends on part size, geometry, and finish requirements.

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

LK Tools offers powder coating as a value-added finishing service for parts produced through our supported manufacturing workflows (such as CNC machining, sheet cutting/fabrication, casting, and other processes). If you have parts supplied from a third party, share details—capability may be limited depending on material condition, surface prep needs, and schedule.

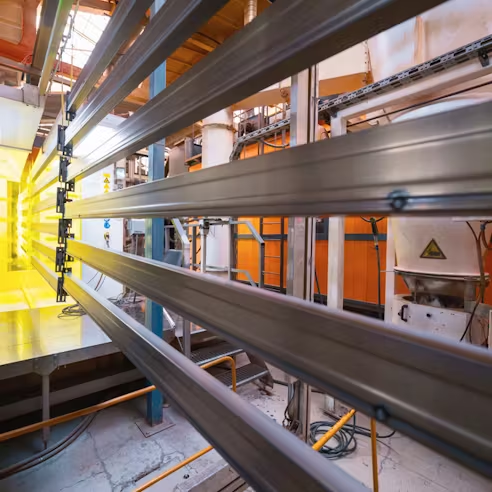

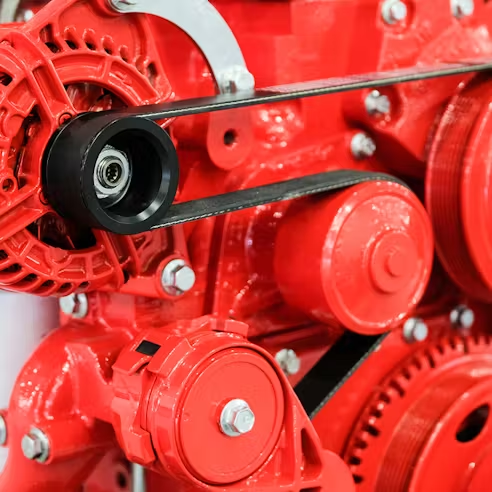

Powder coating provides a continuous protective color finish using evenly applied, heat-cured powder. It’s commonly used to improve corrosion resistance, durability, and appearance on metals such as aluminum and steel. Powder coating is widely used for consumer products, automotive components, outdoor equipment, architectural parts, and industrial hardware.

Powder coating applies a dry, electrostatically charged polymer powder (typically thermoset or thermoplastic) onto a grounded surface using a spray gun. After application, the part is cured—usually in an oven—so the powder melts and flows into a durable, uniform coating.

Compared with many liquid coatings, powder coating can provide strong wear resistance, consistent coverage, and a wide range of colors and textures (project-dependent).

Powder coat application, as opposed to traditional liquid coating, is achieved through a multi-step process. The steps of the powder coating process typically include:

Powder is manufactured by blending resin, hardeners, pigments, and additives, then processing into a fine, uniform powder.

Parts are cleaned to remove oils, dirt, and contaminants. Surface prep may include degreasing, blasting, or chemical pretreatment to improve adhesion.

Powder is sprayed using an electrostatic gun so particles adhere evenly to the grounded part. Complex shapes may require technique adjustments for edges, recesses, and hidden surfaces.

Parts are heated (commonly around 350–400°F, powder-dependent) to fuse the coating into a durable finish. Some specialized systems can use UV curing for heat-sensitive applications (project-dependent).

Coated parts are inspected for coverage, consistency, and visible defects. Touch-ups or rework may be performed when required.

Powder coating can achieve a wide range of appearances from matte to full gloss, including textures. Unless you specify otherwise, a standard finish may be used based on your project requirements.

If you need a specific gloss level, texture, or color match, include that in your quote notes so we can confirm feasibility and provide the correct specification.

Powder coating is most commonly applied to metals. Below are examples of materials often powder coated (availability depends on geometry and condition):

5052 aluminum in the H32 temper is a high strength, corrosion resistant aluminum alloy commonly used for general purpose applications like sheet metal and for applications like marine and transportation products, fuel tanks, architectural products, gutters, window frames, and many other uses.

6061 aluminum in the T6 temper is a high strength, lightweight, and easily machined aluminum alloy commonly used in the production of structural components for a variety of applications including aerospace components, automotive parts, recreational equipment, and construction uses.

7075 aluminum in the T6 temper is an exceptionally high strength and fatigue resistant aluminum alloy commonly used in the production of high stress structural components such as aerospace gears, shafts, aircraft fittings, and other components in extreme environments.

MIC6 aluminumis a trademarked cast aluminum alloy plate by manufacturer Alcoa that is commonly used for tooling and base plates for automotive and aerospace components, as well as for jigs and fixtures.

Abrasion-resistant (AR) 400 and 500 steel are high hardness steels specifically designed to withstand high levels of wear and tear, where they are commonly used in the production of body armor, ballistic plates, and shooting targets as well as in construciton and mining applications.

4140 and 4130 chrome-moly (or chromoly) steel are types of low-alloy steel, where the “40” and “30” designate a 0.40% and 0.30% carbon by weight composition respectively. Both have a high strength-to-weight ratio, excellent tensile and fatigue strength, and good machinability, making them ideal for producing structural components and mechanical parts for automobile and bicycle parts, and tubular products for the oil and gas industry.

304 stainless steel is a type of corrosion-resistant stainless steel thanks to its high chromium and nickel content, making it suitable for a wide range of applications including food processing equipment, kitchen utensils, medical instruments, as well as construction and automotive parts, architectural features, window frames, and more.

316 stainless steel is a type of corrosion-resistant stainless stel with a high level of molybdenum and a lower carbon content than 304 stainless stel, making it exceptionally corrosion resistant and ideal for marine environments, medical implants, chemical processing equipment, as well as high wear construction and architectural applications.

A36 steel is a low-carbon steel with good formability and weldability, making it suitable for use in a wide range of applications, including structural components, tanks, and welded bridges, as well as in the construction of buildings, automotive parts, and other fabricated products like pipes, rods, and beams.

Hot rolled steel is a type of steel formed by rolling at high temperatures (> 1700 °F), resulting in a stronger and more malleable material useful for structural steel bars, sheet metal, and other stock for piping, beams, and automobile parts.

Tool steel is a high-carbon, high-alloy steel that is specifically designed for tool manufacturing. Its ability to be heat-treated and withstand high levels of wear and abrasion make it ideal for punches, dies, cutting edges, hand tools, power tool bits, and automotive parts.

Some benefits of powder coating include:

Powder coating forms a tough protective layer that can resist wear, abrasion, and corrosion better than many liquid coatings (application-dependent).

Provides uniform coverage and consistent color with options for matte, gloss, and textured finishes.

Powder coating is a low‑VOC process compared with many liquid paints because it typically does not rely on solvent carriers.

Efficient material usage and reduced overspray can make powder coating economical for many production programs (project-dependent).

Powder coating is used across many product types, including:

Powder coating is generally best suited to metal substrates that can handle the curing process. In many cases, these categories are not suitable:

Some exceptions may be possible with specialized powders and processes—share details if you have a non-standard material.

When designing for powder coating, consider:

Powder coating adds thickness. A common guideline is ~0.006″–0.012″ total thickness (varies by powder and process). This can affect tight fits, hole diameters, threads, and mating surfaces. Masking may be required for critical interfaces.

Surface condition matters. Porosity, heavy oxidation, or contamination can reduce adhesion. Good cleaning/prep is key.

Color consistency depends on powder type, batch, substrate, and process. For color matching, define an acceptable standard and tolerance.

Complex geometry can increase labor due to masking, racking, and achieving uniform coverage in recesses. In some cases, plating or other finishes may be more practical depending on the requirement.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential