All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

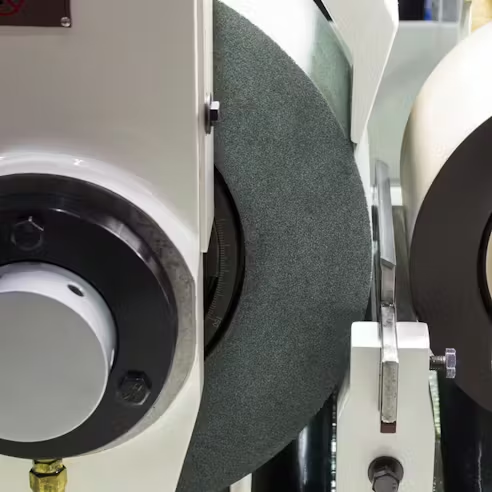

Precision grinding is a finishing process that uses abrasives to remove very small amounts of material to achieve accurate dimensions and smooth surface finishes. It’s often selected when machining alone can’t reliably meet flatness, roundness, or surface finish requirements, or when parts are hardened and difficult to cut efficiently with standard tools.

LK Tools supports multiple precision grinding methods depending on your geometry and functional requirements.

Precision grinding removes material using a rotating abrasive wheel or belt. Because it can remove extremely small amounts of stock in a controlled way, it’s commonly used as a final step to meet demanding tolerances and finish requirements.

Grinding can be used as:

Abrasive selection depends on the workpiece material. Common abrasive families include aluminum oxide, silicon carbide, and diamond (application-dependent). CNC-controlled grinding typically provides the most consistent results for production parts.

LK Tools can support several common precision grinding methods:

A high-throughput method for OD grinding where the part is supported between a grinding wheel and a regulating wheel—without holding the part between centers. Often selected for shafts, pins, and high-volume round parts.

Used to grind internal bores/IDs. The grinding tool is sized for the bore and removes stock to achieve accurate internal diameters, roundness, and surface finish.

Often used for flat parts and planar surfaces. Depending on setup (vertical or horizontal spindle), it can grind flat faces, angles, tapers, and slots (project-dependent).

Precision grinding benefits are listed and described below:

Precision grinding is a cost-effective process because of its ability to achieve precise dimensions in large volumes of parts. Not only is the process fast, but it’s also versatile and highly reliable. Precision grinding can be used on a wide array of materials, including hardened steel and non-ferrous metals, and seldom produces non-conforming parts.

A high degree of accuracy is a huge advantage of precision grinding. In manufacturing, machining processes like milling and turning are used to achieve dimensions close to what is required. While required dimensions can often be achieved with these machining processes, grinding enables manufacturers to remove tiny amounts of material to create extremely accurate parts.

Precision grinding is a highly reliable process. Defects seldom occur during grinding processes, since the process is easy to set up, highly efficient, and applies less pressure to the workpiece than other processes used to obtain precise dimensions like machining.

Tight tolerances are another advantage of precision grinding. With precision grinding, We can achieve tolerances as tight as +0.00025”. Tolerances this low are great for parts commonly manufactured for the automotive, aerospace, and medical industries. Especially in the medical industry where parts are fitted to or implanted into a person’s body, precise parts are absolutely essential.

Precision grinding produces very smooth surface finishes. This is important not just for functionality, such as in medical parts like surgical instruments, but also for the aesthetic qualities of the finished product.

Precision grinding is not without its disadvantages. Some disadvantages of the process are listed below:

Grinding can add cycle time and cost—especially when extremely tight tolerances or cosmetic finishes are required.

Grinding equipment and setup can be expensive, which is why it’s typically used where the value of precision justifies the process.

Grinding can leave fine debris from abrasives or removed material. For high-cleanliness applications, cleaning and handling requirements should be specified.

Precision grinding is common wherever accurate fits and smooth surfaces are required. Examples include:

Used for shafts, gears, bearing surfaces, and drivetrain components where fit and finish affect performance.

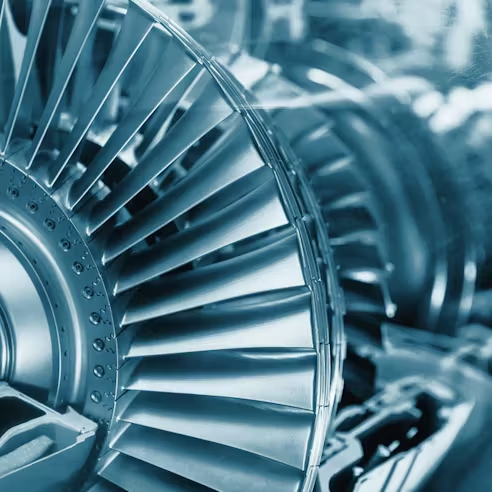

Used for landing gear components, bearing surfaces, and turbine-related parts where precision matters.

Bearings require tight fits and surface finish control. Grinding is frequently used for races and mating components.

Used for motor components, heat sinks, and parts that must fit precisely into compact assemblies.

Used for instruments and components where surface finish and dimensional control are important; requirements vary widely by program.

If grinding isn’t the best fit, alternatives may include:

Used to size and finish internal holes/bores accurately (limited to internal features).

Uses abrasives to improve bore geometry and finish; often selected for roundness/straightness control in holes.

Uses abrasive slurry to achieve very fine finishes and extremely small stock removal; excellent for high-precision flatness or fit requirements (project-dependent).

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become suppliers make it through our qualification process.

All uploads are secure and confidential