STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

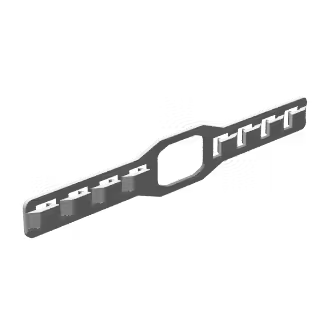

Metal stamping forms coil or sheet material into finished shapes using a press and a set of dies. Depending on part geometry and production needs, stamping may include operations such as blanking, punching, embossing, bending, and progressive-die forming.

Stamping is widely used to produce repeatable parts at scale—from brackets, clips, and connectors to larger panels and formed housings. Once tooling is built and validated, stamping can deliver excellent throughput and consistent part-to-part quality. For tighter critical features, secondary operations (such as machining, deburring, or finishing) may be added as needed.

LK Tools supports stamped parts across a range of materials and stamping methods. During quoting, we review your design and drawings to recommend an appropriate stamping approach based on complexity, thickness, tolerance needs, and target quantities.

Stamping is often chosen when you need repeat production of formed sheet metal parts with predictable unit cost at volume.

Common advantages include:

Stamping is powerful, but it has tradeoffs—especially early in the program.

Common disadvantages include:

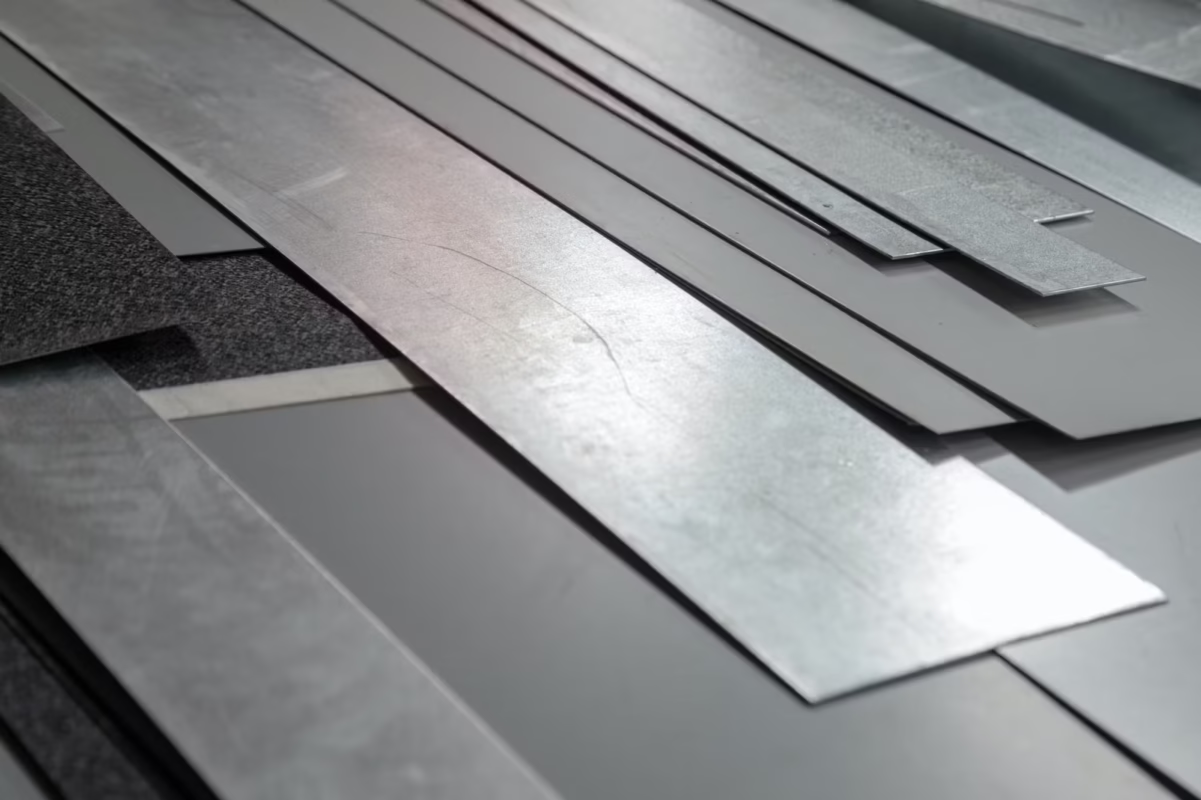

LK Tools supports stamping across common sheet metals. Availability depends on thickness, temper, and sourcing.

Common stamping materials include:

Other sheet metals may be possible upon request. If you have a specific grade/temper or certification requirement, include it in your RFQ.

Finishing note (keep as a short line):

Stamped parts can be post-processed with finishes such as bead blasting, powder coating, chemical films, anodizing (material-dependent), or plating (project-dependent).

Different stamping methods are used depending on geometry, thickness, and volume. LK Tools can help match your design to the most practical process.

Stamping volume expectations strongly influence the best tooling approach and overall economics.

Low Volume Production

Often used for bridge production, pilot runs, or controlled demand—typically most cost-effective once minimum tooling economics are met (program-dependent).

Medium Volume Production

Balances per-part cost and flexibility while taking advantage of stable stamping throughput.

High Volume Production

Best when demand is stable and high. Unit cost typically decreases as volume increases once tooling is amortized.

Short Run Stamping

Limited production with fewer process changes—often used for stable designs and limited quantities.

Long Run Stamping

Optimized for sustained production where the line may be tuned over time for quality, throughput, and cost.

Stamped part tolerances depend on material, thickness, geometry, tool design, and the selected stamping method. For tight or critical-to-function features, suppliers often validate and refine the die design to hit the required output. Secondary operations (reaming, machining, deburring) may be used for features that require tighter control.

For best results:

Metal stamping supports many industries and part types. Common sectors include:

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

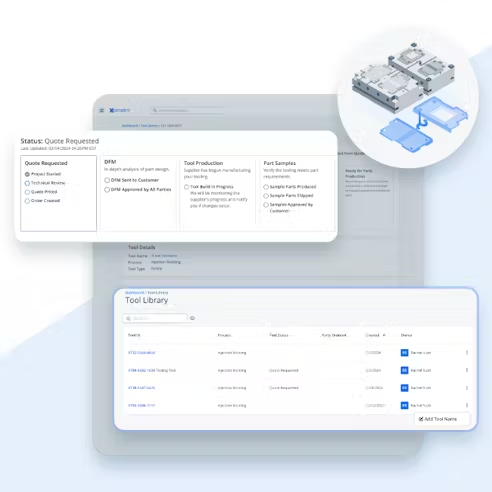

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become suppliers make it through our qualification process.

For tooling-based programs, revision control and clear status updates help maintain consistent production. If you need structured management for die revisions, approvals, and repeat releases, tell us during quoting so we can align the workflow.

Benefits (bullets):

All uploads are secure and confidential