High-quality, cost-effective custom plastic extrusions for production programs and repeat supply.

STEP | STP | SLDPRT | IPT | PRT | SAT

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

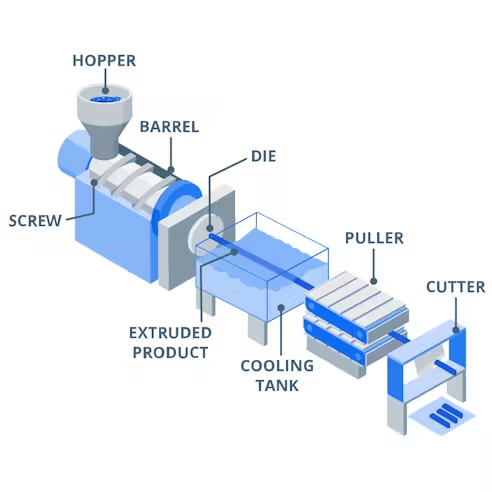

Plastic extrusion converts thermoplastic pellets into a continuous length of material with a consistent cross-section. During the process, pellets are fed into a heated barrel and driven forward by a rotating screw until the material becomes molten. The melt is then pushed through a screen/filter and forced through a shaped die that defines the final profile.

After exiting the die, the profile is pulled at a controlled speed, cooled (often with water or air), and then cut to length or wound—depending on the product type. Because the cross-section remains constant, extrusion is ideal for tubing, channels, trim, protective strips, seals, and other long profiles.

Some extrusions include internal cavities (lumens). Multi-lumen tubing is used to separate flow paths or create lightweight structures while keeping uniform wall thickness (feasibility depends on profile design and material).

Plastic extrusion supports many industries including construction, utilities, telecommunications, industrial equipment, and consumer products—anywhere a stable, repeatable profile is needed.

Creating custom plastic extrusions allows designers to build a profile that fits their application exactly—often reducing part count and simplifying assembly. Profiles can also be produced in specific colors, hardness ranges (for elastomers), and lengths depending on material and process.

Upload your CAD (or a drawing of the cross-section) and requirements so we can review feasibility and quote your program. For extrusion projects, the most important inputs are the cross-section geometry, material, tolerance targets, lengths, and annual volume.

If you only have a 2D profile or sketch, include key dimensions and functional requirements and we can help translate it into an extrusion-ready specification.

Lead time depends on die complexity, material sourcing, color requirements, and the amount of sampling needed before full production. For many programs, we can support an efficient path from die build → first articles → repeat production once the profile is validated.

If you have a deadline, include your target date and quantity so we can recommend the most practical plan.

Extrusion is often cost-effective for production volumes because it runs continuously and uses relatively simple tooling compared with many other processes. A well-designed profile can replace multi-part assemblies, reduce labor, and lower total program cost.

Tooling cost is typically lower than hard tooling required for injection molding or die casting, making extrusion attractive for long-length profiles and high-volume applications (project-dependent).

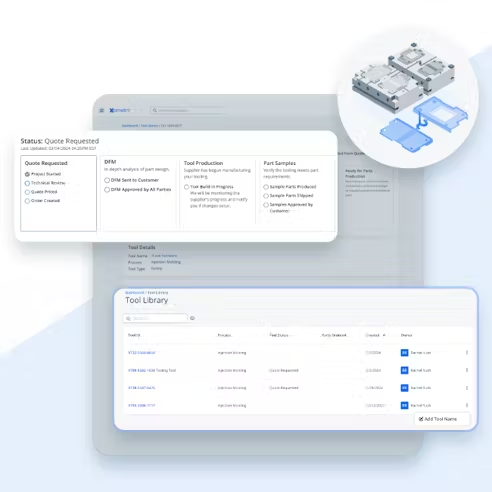

Upload your files and requirements (profile, material, color, length, quantity/forecast). We review feasibility and provide DFM feedback for the cross-section and tolerance strategy before tooling begins.

We build an extrusion die and produce initial samples for dimensional and functional approval. Adjustments can be made based on measurement results and fit testing.

After approval, we move into repeat production and deliver parts based on your schedule. We can also support packaging and cut-to-length requirements depending on the program.

For ongoing extrusion programs, tool management and revision control help keep production consistent. If you anticipate future profile revisions, multiple lengths, or recurring releases, we can help define a simple management workflow for tooling details, sample approvals, and reorder scheduling.

Benefits (bullets):

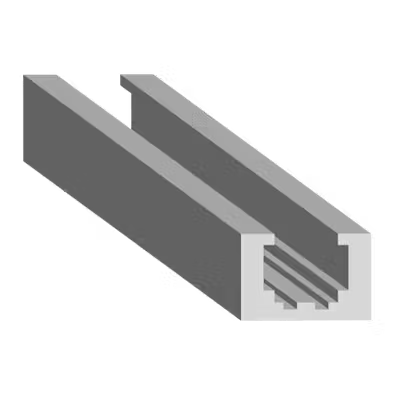

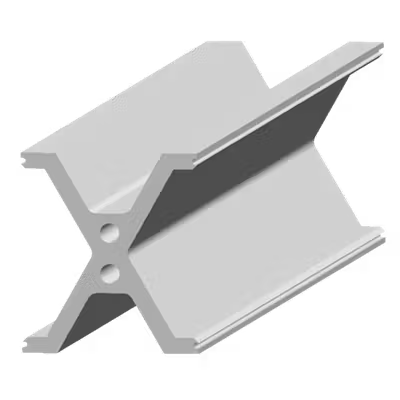

Extrusion profiles can be open or closed depending on the application. Closed shapes include round and square tubing, multi-lumen tubing, and enclosed profiles designed for standards or fittings. Open shapes include U-channels, J-channels, L-profiles, trim, and custom geometries for specific assemblies.

Plastic extrusions are used across many industries. Common examples include:

Extruded conduit and channels protect wiring and help reduce damage in residential, commercial, and industrial installations.

Plastic pipe and tubing is widely used for water, waste, and fluid routing because it resists corrosion and many chemicals.

Extruded trim protects sharp edges, improves fit/finish, and can provide sealing and vibration control for consumer and industrial products.

If you don’t see your target material, include it in your request availability can depend on profile complexity and supplier capabilities.

Economical and flexible with good chemical resistance; common for tubing and protective profiles.

Often used for plumbing-related applications due to improved temperature and chemical resistance.

Rubber-like flexibility with thermoplastic processability; useful for seals, grips, and soft-touch profiles.

Widely used for general-purpose tubing and construction profiles; multiple formulations exist for different environments.

Good strength and appearance; often used for trim, housings, and structural profiles.

Used for insulation and lightweight foam profiles in appropriate grades.

Durable and fatigue resistant; often used for tubing and consumer/industrial profiles.

Impact resistant and dimensionally stable; selected for tougher profiles and protective components.

Modern extrusion processes can produce consistent profiles with stable dimensions when design and process controls are aligned.

Continuous production and efficient material usage can make extrusion economical at volume.

Extrusion tooling is often simpler and less expensive than many hard-tooling processes.

Extrusion can support complex cross-sections including grooves, channels, and internal features that remain constant along the length.

Tooling, line setup, minimums, and sampling iterations can add upfront cost before production.

The cross-section must remain constant. Features like pockets, bosses, and countersinks typically require secondary operations.

Die build and sampling can take weeks depending on complexity, material, and revision cycles. Initial deliveries are commonly longer than repeat reorders.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get started with our easy-to-use platform and let our experts manage the project, from locating the right manufacturing Supplier to delivery logistics.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become suppliers make it through our qualification process.

All uploads are secure and confidential