STEP | STP | SLDPRT | STL | DXF | IPT | 3MF | 3DXML | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

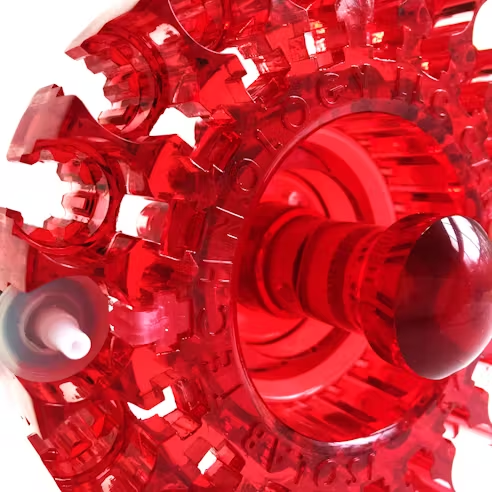

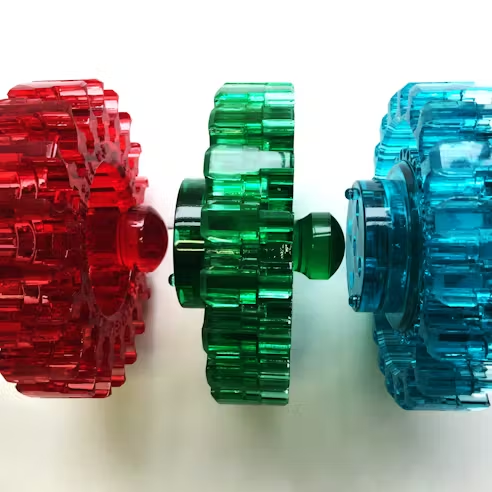

Urethane casting produces rigid, flexible, and rubber-like parts with excellent surface quality—making it a strong choice for low-volume production and high-fidelity prototypes. The process uses a master pattern (commonly made via high-resolution 3D printing) to create an RTV silicone mold, which is then used to cast multiple parts.

Because the tooling is “soft” silicone rather than machined metal, urethane casting offers a practical balance of quality, cost, and speed for short runs. It’s commonly used for parts up to large sizes (project-dependent), and it can support cosmetic requirements such as smooth surfaces, color matching, clear parts, and painted finishes.

Final dimensions depend on master pattern accuracy, geometry, and chosen casting material. As a general guideline, small dimensional change due to shrinkage can occur, and should be considered for critical features (we can advise during review).

Urethane and silicone casting are often used as a bridge between a 3D printed prototype and injection molding, or as an alternative for low volumes when hard tooling is not yet justified. Inserts and secondary finishing may be supported depending on design requirements.

Polyurethane is a versatile thermoset family known for strength, abrasion resistance, and the ability to mimic common thermoplastics. Different urethane systems can be selected to approximate “PC-like,” “PP-like,” or elastomeric behaviors depending on the use case.

We group urethane options into performance categories to help you choose quickly based on stiffness, impact resistance, clarity, and cosmetic goals.

(If you want a specific material list table here, tell me which urethane systems you actually offer and I’ll format it.)

Note: Equivalent materials may be used depending on availability and production location.

(Add your material menu here, or keep this section short and link to a materials page.)

Silicone is a durable, flexible material option for parts that need softness, tear resistance, easy cleaning, and temperature stability. Silicone casting can achieve very soft durometers for grips and seals, as well as medium hardness for protective housings and functional elastomer components (project-dependent).

Common durometer ranges (examples):

(Exact material grades depend on availability; we can recommend options during quoting.)

Diffused appearance to reduce glare and hide handling marks.

Balanced cosmetic finish for consumer and industrial parts.

Light texture to improve grip or hide surface variation (project-dependent).

Urethanes can be pigmented to achieve a variety of colors. Natural urethane can range from amber to milky-white depending on the system. Clear casting options may be available for eligible designs and cosmetic requirements.

Color options (examples):

Urethane cast parts are perfect for low-quantity production—when volumes do not justify investment in injection mold tooling—as well as for first run production parts, which can be completed weeks before production tooling is ready.

The urethane casting process and relatively inexpensive tooling involved makes it easy and economical to make any necessary design changes. Additionally, different materials can be used with the same mold, making it possible to test designs with a variety of materials.

End-user functionality and a high-quality finish makes urethane cast parts ideal for consumer testing, user evaluation and concept models. Using the cast urethane process means that changes can be incorporated quickly for either further testing or market launch.

Urethane casting is a soft-tooling process used to produce high-quality plastic or elastomer-like parts in low volumes. A silicone mold is created from a master pattern, then filled with liquid urethane or silicone that cures into the final part.

Urethane casting is similar in concept to molding processes that use a cavity tool, but it uses silicone tooling rather than machined metal tooling. Silicone molds wear out faster than hard tooling, but they’re much more economical for short runs and pilot builds.

A typical workflow includes:

Master pattern creation

A master pattern is produced—often with high-resolution 3D printing (e.g., SLA-like processes) and hand-finished for best surface quality.

Silicone mold creation

The master is encapsulated in silicone. Once cured, the mold is split and the master is removed, leaving a precise cavity.

Casting and curing

Liquid urethane or silicone is poured into the mold. Vacuum/pressure steps may be used to reduce bubbles and improve surface quality. After curing, the part is removed and the cycle repeats until the target quantity is met.

Urethane casting is a strong choice when you need production-like surface quality without investing in hard tooling. It can produce rigid, flexible, clear, colored, and rubber-like parts with minimal post-processing compared with many additive methods.

Typical tolerances depend on master accuracy, part size, geometry, and material. Designs should include adequate draft, radii, and coring where appropriate. For critical dimensions, include a 2D drawing with explicit tolerances so we can plan measurement and process controls.

Casting can provide smoother cosmetic surfaces and production-like appearance, especially for short-run parts where post-processing 3D prints would be time-consuming.

For low volumes, casting avoids the cost and lead time of hard tooling while still providing high-quality parts for validation and market testing.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential