Make strong, functional prototypes and production parts with insert molding.

STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

LK Tools supports insert molding as part of our injection molding capabilities. Upload your CAD files and requirements and we’ll prepare a quote and manufacturability review. If your part needs molded-in threads, wear-resistant interfaces, or stronger mounting points, insert molding can be a very effective solution.

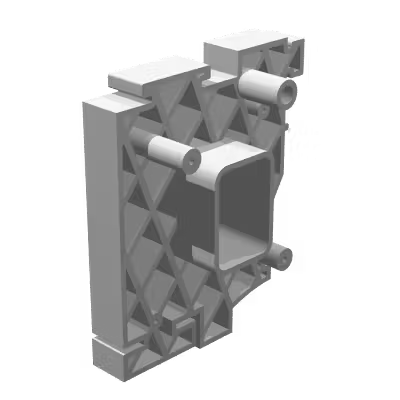

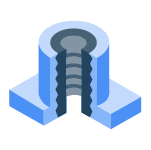

Insert molding is an injection molding process where a pre-made insert (often metal, but sometimes another material) is placed into the mold and plastic is molded around it. It’s commonly used for parts that need durable threaded holes, improved strength at fastening points, or reliable electrical/mechanical interfaces.

If insert molding isn’t the best fit for your stage or geometry, we can also recommend alternatives such as standard thermoplastic molding, overmolding, urethane casting, or 3D printing—based on quantity, performance needs, and timeline.

Insert molding is commonly used when parts need reliable fastening points, reinforced interfaces, or durable threads for repeated assembly.

Once the design is stable, insert molding scales well into repeat batches—helping maintain consistent fit, torque performance, and assembly reliability.

If your program requires documentation, traceability, or special handling/inspection expectations, include those requirements in your RFQ so we can align the process plan.

Single‑material molding for prototypes through production with a wide selection of resins and finish options.

Combine a soft material over a rigid substrate for grip, sealing, vibration damping, or improved ergonomics.

Prototype tooling, bridge tooling, and production tooling strategies based on quantity, cosmetics, and tool life.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential