STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

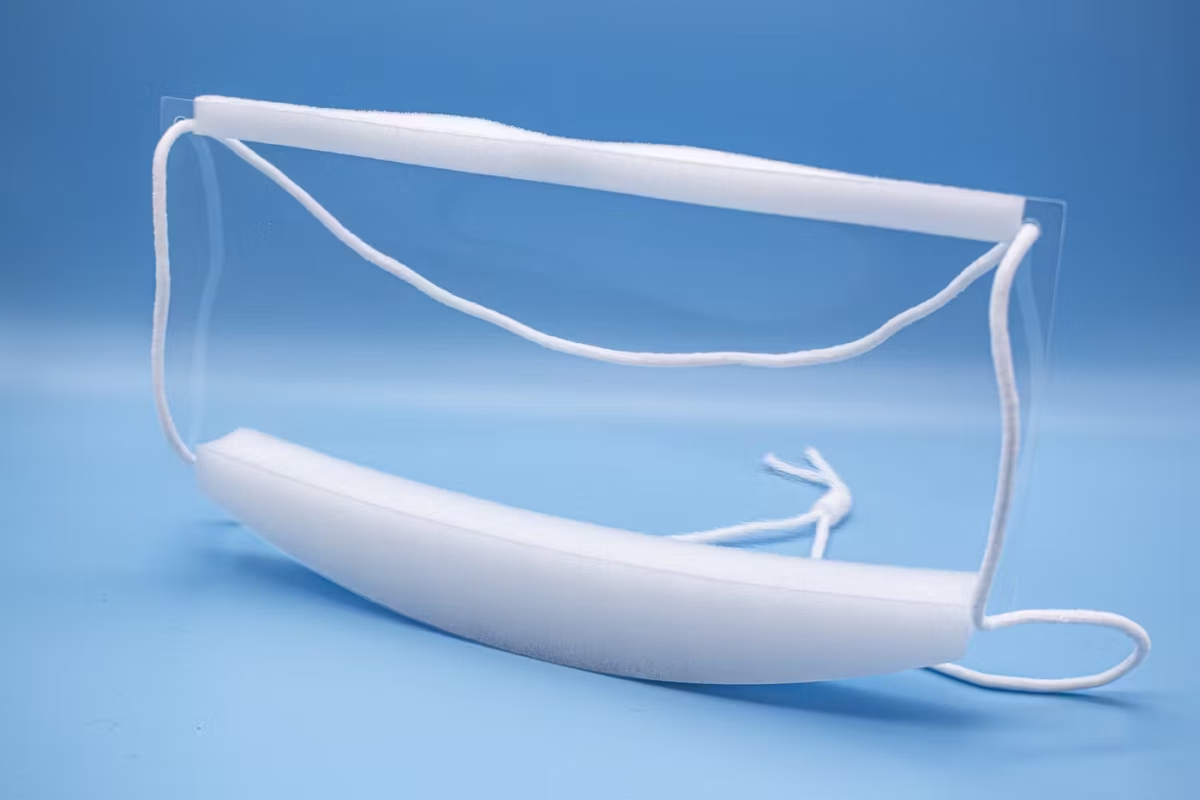

LK Tools provides hands-on support for production injection molding programs where schedule, repeatability, and supply continuity matter. High-volume production requires more than just a mold—successful programs depend on stable processes, clear specifications, inspection strategy, and reliable logistics.

Our production molding services complement earlier-stage options such as prototype molding and bridge tooling. Once your design is validated, we help transition into long-life tooling and sustained production. We coordinate tooling build, sampling approvals, and repeat manufacturing while keeping communication simple and project status visible.

Advantages you can expect with LK Tools:

Use this section to highlight a real program where production molding scaled from pilot builds into ongoing high-volume supply with consistent quality and delivery performance.

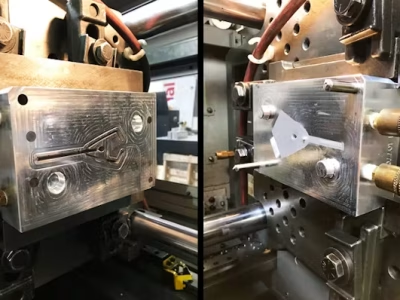

Upload your CAD and drawings with requirements (material, color, finish, quantity forecast, critical dimensions). We review the request and provide DFM feedback before tooling begins.

After tooling is built, first samples (T1) are produced for approval. We align on any required refinements and confirm final process settings for repeatability.

Once samples are approved, we move into production runs based on your schedule. Repeat orders can be supported with consistent process control and agreed inspection requirements.

Production tooling is designed for higher volumes and long-term repeatability. While it is typically a larger upfront investment than prototype or bridge tools, it supports longer tool life, more stable processing, and better suitability for sustained demand.

Production tooling may enable:

Insert your tool-level comparison chart here (prototype vs bridge vs production). If you paste your table contents, I can rewrite the row/column descriptions to match LK Tools while keeping the layout identical.

Production programs often require structured quality expectations. LK Tools can support documentation and inspection options depending on your program requirements. Share your quality needs at RFQ so we can align the process plan and measurement method.

Common options (project-dependent):

(If you truly have ISO/AS9100/IATF/ITAR/cleanroom capabilities, tell me exactly which ones and I’ll add them accurately.)

Injection molding is widely used across consumer products, industrial equipment, electronics, automotive, and medical/lab equipment. Requirements vary by application.

Lead time depends on tool readiness, production schedule, resin availability, finishing, and inspection requirements. We confirm timing for each release.

Many production-grade resins are available depending on functional requirements. Share heat, chemical exposure, impact, and compliance needs.

Color changes are often possible depending on resin and process. Multi-material molding (overmolding) is possible for eligible designs.

Tool ownership, storage, and maintenance terms are defined during quoting and ordering.

Shipping depends on destination, packaging requirements, quantity, and delivery speed. We can quote shipping as part of your order.

We align requirements → DFM review → tooling build → sampling approval → production releases and repeat orders.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Our experts help get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, IATF 16949:2016 and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential