STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

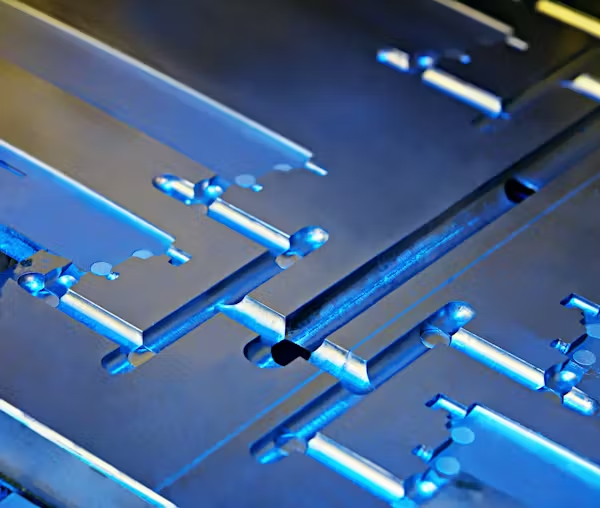

LK Tools supports product teams through every stage of molding—from early prototypes to sustained production. Bridge tooling is the step between prototype tooling and long-life production molds. It’s designed for teams that need molded parts sooner, want to validate manufacturing readiness, or need a limited production run before investing in high-volume tooling.

Compared with prototype tooling, bridge tooling typically expands your options for tool life, output, gating strategy, and mold configuration. It can also support more robust process development before you commit to long-life tooling—helping reduce risk when you scale.

During quoting, our engineers review your design and requirements (material, finish, quantity, tolerance, inspection needs) and recommend a tooling strategy that balances speed, cost, and repeatability.

Bridge tooling is often the “sweet spot” when you need real molded parts without waiting for long-life production tooling.

Key benefits include:

Use this section to highlight how bridge tooling helped a customer meet early demand, validate production readiness, and scale efficiently.

Bridge tooling is a good fit when your design is mostly stable, but you still need flexibility—either to validate the part under real conditions or to meet near-term demand.

Consider bridge tooling when:

Insert your comparison table here (prototype vs bridge vs production). If you paste your table values, I can rewrite the row labels and descriptions to match LK Tools and make it read original while preserving your exact structure.

Injection molding is used across consumer products, industrial equipment, electronics, automotive, and medical/lab equipment. Requirements vary by program.

Lead time depends on part complexity, tooling approach, resin availability, and finishing requirements. We confirm timing during quoting.

Many common production resins may be available depending on application needs. Share functional requirements (impact, heat, chemical exposure) and we’ll recommend options.

Mold classes describe tool durability and expected production life. The right class depends on volume, resin, and design complexity.

MUD (Master Unit Die) tooling is a modular approach that can reduce tool cost and build time for certain parts (project-dependent).

Tool ownership and storage terms can vary. We can define ownership, maintenance expectations, and access during quoting.

Minor revisions may be possible depending on the change and tool design. We’ll review the request and confirm impact on cost and schedule.

We align requirements → DFM review → tooling build → first samples for approval → production run based on confirmed quantity/finish.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Our experts help get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential