Get production-intent molded parts for validation builds and early pilot runswithout committing to full production tooling upfront. LK Tools supports low-cost prototype tooling, material selection, and DFM review so you can move faster and de-risk your product.

STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

LK Tools helps teams turn early designs into molded parts that behave like production—so you can validate fit, assembly, and functional performance before investing in long-life tooling. While CNC machining and 3D printing are great for early iterations, prototype injection molding is often the next step when you need real molded geometry, production-grade materials, and repeatable parts for testing and customer samples.

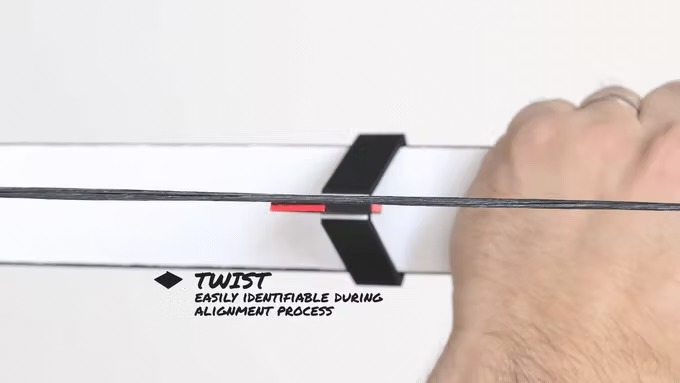

Our prototype molding service is designed to keep things flexible. We can use many of the same resin and finishing options available in full production molding, while focusing the tooling approach on speed and cost for limited runs. During quoting, our engineers review your design and recommend changes that improve moldability and reduce risk (draft, wall transitions, ribs/bosses, undercuts, parting line strategy, and gating considerations).

Not sure whether to begin with prototype molding or go straight to production tooling? Prototype injection molding is often a smart first step when you want to validate your product with production-like parts, but you’re still refining design details or demand forecasts.

Prototype molding may be a strong fit when you need:

Use this block to highlight a customer example where prototype molding solved a functional challenge and accelerated product validation.

Every process has tradeoffs. Prototype injection molding is powerful, but it works best when design and expectations are aligned with prototype tooling.

Key considerations include:

If you need fewer limitations, higher volumes, more aggressive cosmetic requirements, or longer tool life, you may be better served by bridge tooling or production tooling. LK Tools can recommend the right path during quoting.

Injection molding is used across consumer products, industrial equipment, electronics, automotive, and medical/lab equipment. Requirements vary widely by application.

Prototype molding gives you production-intent resin performance and molded part geometry, which helps validate fit, assembly, surface finish, and end-use behavior.

Mold classes describe tooling durability and expected production life. The right class depends on quantity, material, and part complexity.

MUD (Master Unit Die) tooling is a modular tooling approach that can reduce tool cost and build time for certain parts (project-dependent).

Lead time depends on part geometry, tooling approach, resin availability, and finishing requirements. We confirm schedule during quoting.

Many common molding resins are available, depending on project needs. Share functional requirements (impact, heat, chemical exposure) and we’ll recommend options.

Often yes, depending on resin and coloring approach. Share color requirements and cosmetic expectations.

We align requirements → provide DFM feedback → build tooling → produce first samples for approval → proceed with the agreed quantity and finishing.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Our experts help get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

Practical DFM tips for draft, ribs, bosses, wall thickness, tolerances, and cosmetic surfaces.

All uploads are secure and confidential