STEP | STP | SLDPRT | IPT | PRT | JT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

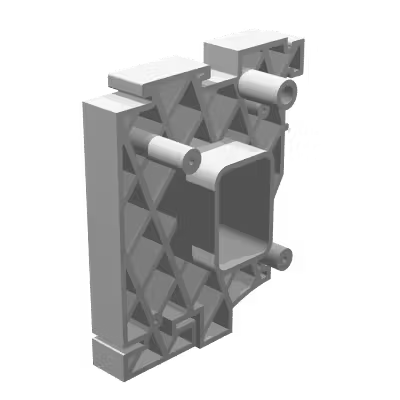

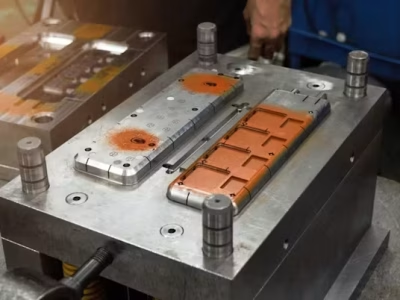

Injection molding is one of the most cost-effective ways to manufacture plastic parts at scale. Molten resin is injected into a precision-machined mold, cooled, and then ejected as a finished part. The cycle repeats quickly, producing consistent parts once the tooling is validated.

Because the same mold creates every part, injection molding is ideal when you need repeatability, stable dimensions, and a defined surface appearance. It also supports a broad selection of plastics, colors, textures, and surface finishes—often more than what’s practical with CNC machining or 3D printing.

LK Tools supports both prototype and production injection molding projects. We help validate design details (draft, wall thickness, ribs, bosses, and undercuts), confirm material selection, and plan a tooling approach that matches your volume, cost, and timeline requirements.

This section summarizes general capability and tolerance guidance for plastic injection molding. Actual results depend on part geometry, resin, tooling class, and inspection requirements. For critical dimensions, include a 2D drawing with explicit tolerances and GD&T (if applicable) so we can plan measurement and control methods.

Line (optional):

Learn more about our molding standards during the quoting process.

SPI mold classes are commonly used to describe tooling durability and expected production life. The best class depends on your annual volume, resin choice, and part complexity.

Best suited for early prototypes and short runs where speed and cost matter most. Often used to validate design and fit before moving to higher-life tooling.

A practical option for pilot builds and limited production. Useful when you need better durability than prototype tooling but don’t require long production life.

Designed for moderate production volumes. Often selected when repeatability and tooling life become more important.

Built for higher production volumes with stronger tool construction and improved durability. A common choice for sustained production programs.

(If you want, tell me your preferred mold class offerings and I’ll align this to your real service.)

Injection molding requires an injection press, plastic resin, and a precision-machined mold (often aluminum or steel depending on program needs). Resin is melted, injected into the cavity, cooled, and then ejected as a finished part.

At LK Tools, we start by reviewing your quote request and design requirements. We then provide DFM feedback (draft, parting line, gating, ribs/bosses, and tolerance risk areas) and align on tooling strategy. After tooling is built, first samples are produced for approval, and adjustments can be made if required. Once validated, we proceed into production and manage repeat orders based on your schedule.

(Keep the same list, but use shorter, non-copied descriptions. You can paste the list below as-is into Elementor.)

Elastomeric parts may be produced via injection molding, transfer molding, or compression molding depending on geometry and volume. Share your sealing, temperature, and chemical exposure needs so we can recommend the best approach.

Closing line (keep):

If you don’t see the material you need, choose “Other” and include your requirements for an engineering review.

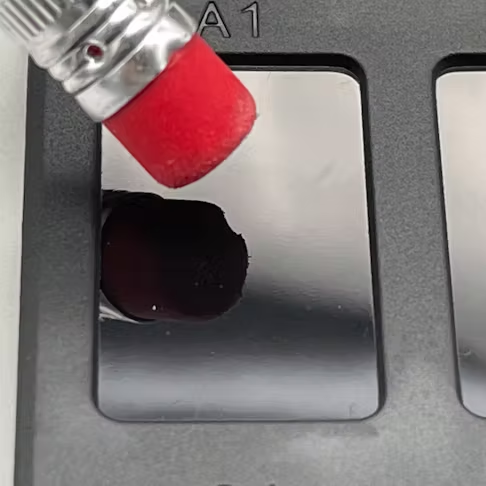

Moldmaker’s choice of finish. Typically SPI B-2, depending on geometry and drafts. Interior, non-cosmetic faces, are typically as-machined.

Range of Society of Plastics Industry (SPI) finishes from Grade 3 diamond / high polish to 320 stone low polish. Finishes include: SPI A-1, SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2, and SPI D-3

Range of finishes including matte, swirls, lines, and patterns. Our most common texture finishes include: MoldTech MT11010, MoldTech MT11020, and MoldTech MT11030. Other textured finishes can be added by request.

VDI 3400 Surface Finish (commonly known as VDI surface finish) refers to the mold texture standard set by Verein Deutscher Ingenieure (VDI), the Society of German Engineers. This is mainly processed by EDM machining, producing fine to coarse matte finishes.

No secondary polishing or grinding. Part will show tooling marks.

We can install most commonly used standard inserts in UNF and metric sizes.

Transfer a 2D image onto a 3D part. All images are subject to review.

Engrave part numbers, logos, and more onto your parts.

We have the ability to assemble and label injection molded parts. Discuss your needs with your salesperson.

Good injection molding design improves part quality and reduces tooling changes. If you’re early in design, share your file for a quick DFM review.

Validate fit, function, and assembly with production-intent materials using prototype or bridge tooling.

Repeatable parts with stable dimensions and consistent appearance at scale once tooling is validated.

Used across consumer products, industrial equipment, electronics, automotive, medical/lab equipment (requirements vary by program).

Injection molding is used across consumer, industrial, electronics, automotive, and medical/lab equipment. The best approach depends on material, tolerance, and regulatory requirements.

3D printing is typically best for fast iteration and complex geometry at low quantities. Injection molding is best when you need repeatable parts and lower unit cost at higher quantities.

We review the design, confirm tooling strategy, build the mold, produce first samples for approval, then move into production after confirmation.

Tool ownership can vary by project terms. We can define ownership, storage, and maintenance expectations during quoting.

Often yes, depending on the resin and coloring method. Share your color requirements and cosmetic expectations.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

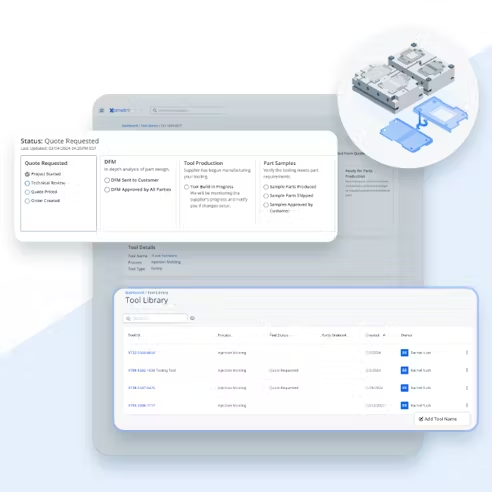

For tooled programs, we can help organize tooling details, revisions, and production status so teams have clear visibility as projects move from sampling to repeat production. If you need tool revision control or structured communication, tell us during quoting so we can align on workflow.

Benefits (bullets):

All uploads are secure and confidential