STEP | STP | SLDPRT | IPT | X_T | X_B | CATPART | PRT | SAT | JT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

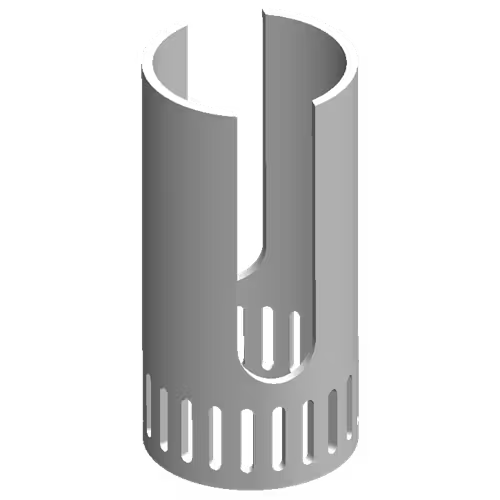

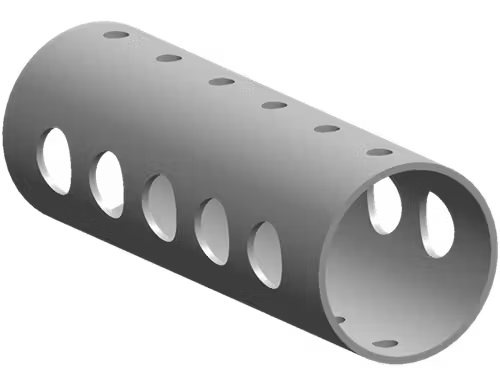

Laser tube cutting is a process that uses a controlled laser to cut holes, slots, profiles, and end shapes into tube or pipe stock. During cutting, the tube is held and rotated while the laser follows programmed toolpaths—allowing features to be placed accurately around the tube circumference.

This method is commonly used to create ready-to-weld joints, assembly slots, drainage/vent holes, and complex profiles that would be slow or difficult with traditional drilling and sawing. Laser tube cutting can also create relief features that make downstream bending or fitting more consistent.

LK Tools supports laser tube cutting for prototypes and repeat production. If you share your CAD model, target material, wall thickness, and critical features, our team can confirm manufacturability and recommend practical adjustments to improve fit-up and reduce cost.

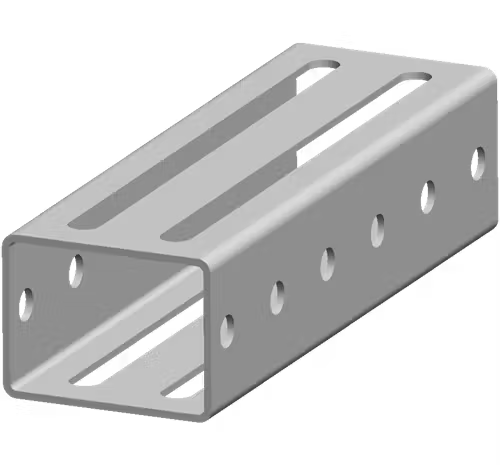

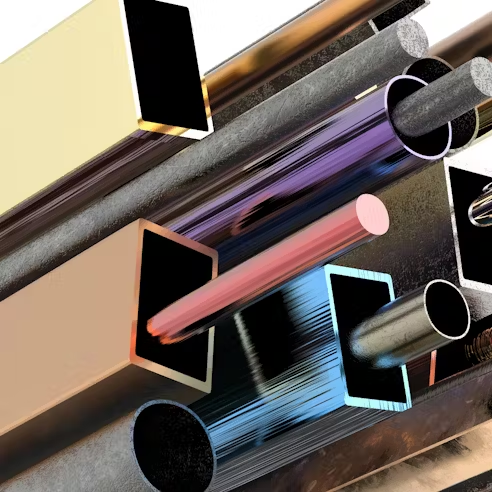

Our tube laser cutting service supports common round, square, and rectangular tube profiles in a range of sizes and wall thicknesses. Kerf width and edge quality can vary based on material type, laser settings, assist gas, and wall thickness, but laser cutting generally produces a narrow cut and efficient material usage.

Typical size range (confirm during quoting):

General tolerance guidance (project-dependent):

If you have critical fit-up features (tabs/slots, weld joints, tight assemblies), include a 2D drawing with explicit tolerances so we can validate the best cutting strategy.

Laser tube cutting systems are designed to handle common tube profiles including round, square, and rectangular tubes. Other profiles may be possible depending on availability and setup.

Common material options (subject to availability):

If you need a specific standard, temper, or certification, include it in your RFQ and we’ll confirm sourcing and lead time.

Laser tube cutting systems vary based on application and production needs. Some machines are combination systems that can cut both flat sheet and tube, which can be convenient for mixed projects. Dedicated tube cutting systems are optimized for tube stock and can support longer lengths and a wider range of tube profiles.

Laser tube cutting can be performed with different laser types depending on the material and performance requirements. In general, fiber lasers are widely used for metal cutting and offer strong versatility across materials. CO₂ lasers may be selected for certain applications based on material and edge requirements. Our team will match the cutting approach to your tube material, wall thickness, and geometry.

Machine capability is often defined by tube size range, max length/weight handling, assist gas options, and automation (manual loading vs. conveyor/automatic feeding). For production programs, automated handling can improve throughput and repeatability.

Advantages of laser tube cutting:

Limitations to consider:

Access the capacity of hundreds of laser tube cutting suppliers through our easy-to-use platform.

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified. Only the top shops that apply to become network suppliers make it through our qualification process.

Our team of Solutions Engineers and Process Specialists are available to support you and provide answers to all of your fabrication and manufacturability questions.

All uploads are secure and confidential