Instant quotes and cost-effective, on-demand fabrication for flat-cut parts.

STEP | STP | SLDPRT | DXF | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

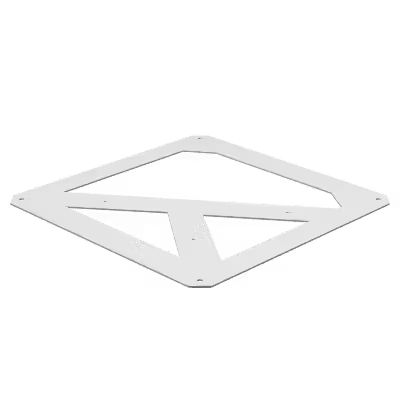

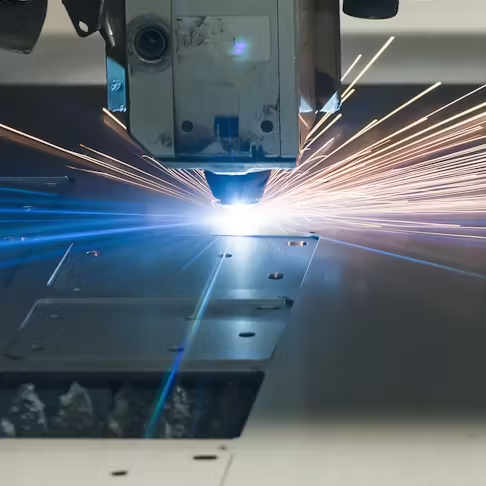

Waterjet cutting (also called abrasive waterjet cutting) uses a high-pressure stream of water—often combined with an abrasive media—to cut material accurately without adding significant heat. Because it is a cold-cutting process, it helps reduce thermal distortion and avoids a heat-affected zone (HAZ), which can be important for parts that need stable material properties.

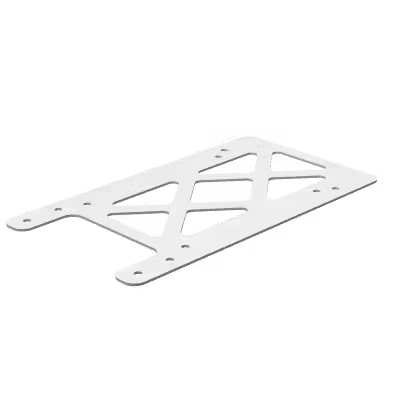

Modern waterjet systems are CNC-controlled, allowing repeatable cutting of complex profiles, holes, and internal features. Waterjet is commonly used for industrial components, brackets, panels, gaskets, and prototypes where versatility and material compatibility are key.

LK Tools provides waterjet cutting as an on-demand solution for prototypes and production parts. If your application is better suited for laser cutting, CNC routing, or machining, we can recommend the most practical process during quoting.

DXF is one of the most common formats for sheet cutting projects. To keep your quote accurate and production-ready, our team checks for common DXF issues and confirms key details such as units, closed profiles, duplicate geometry, and nesting strategy (if applicable).

Below are a few ways we help streamline DXF-based waterjet quoting:

Waterjet cutting supports a wide range of materials and thicknesses. Availability depends on your requirements—share your material spec and thickness in your RFQ.

Waterjet can cut virtually any material, making it perfect for preparing material blanks to near-net shape.

The range of materials available, low cost per unit, and speed of production makes waterjet a great option for prototyping.

Large format cutting, vast material options, and high throughput have made waterjet a favorable technology for end-use parts.

Free shipping available for domestic waterjet orders

Similar to CNC machining, sheet metal processes produce highly durable parts well-suited for both functional prototypes and end-use production.

All sheet metal parts are built on-demand and with lower setup costs compared to CNC Machining. Depending on your needs, order as little as a single prototype up to 10,000 production parts.

Combining the latest cutting, bending and punching with automated technologies, Xometry provides instant sheet quotes and completed parts in as little 12 business days.

Choose from a variety of sheet metals across a wide range of strength, conductivity, weight, and corrosion-resistance.

General tolerances depend on material type, thickness, geometry, and cut quality requirements. For critical dimensions, include a 2D drawing with explicit tolerances or GD&T. LK Tools can support inspection requests such as dimensional reports when required.

A waterjet cutter is an industrial system used to produce flat-cut parts by focusing water into a high-pressure stream. For softer materials, pure water cutting may be used. For harder materials, an abrasive is added to help cut metals and tough composites.

A high-pressure pump drives water through tubing to a nozzle, creating a focused jet that removes material along a programmed path. In abrasive cutting, abrasive media (commonly garnet) is mixed near the nozzle and exits with the water stream to enable cutting of harder materials.

CNC control improves repeatability and accuracy by controlling nozzle motion, speed, and cutting parameters. For thicker materials, process settings and strategy help reduce taper and improve edge quality.

Waterjet cutting is often selected when you need to avoid heat input, cut thicker materials, or work with materials that are difficult to laser cut. It’s also a strong choice for complex 2D shapes and internal cutouts where consistent edge quality matters.

Compared with thermal cutting methods, waterjet can reduce risk of heat-related distortion. It can also be an efficient option for parts that require minimal post-cut cleanup, depending on the cut quality level specified.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential