STEP | STP | SLDPRT | DXF | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

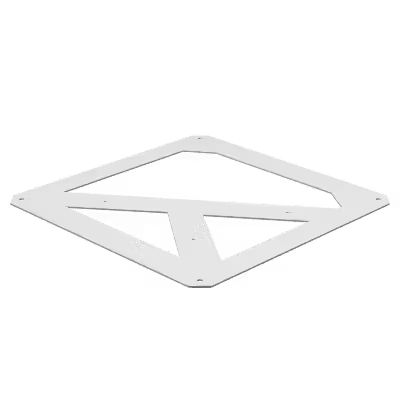

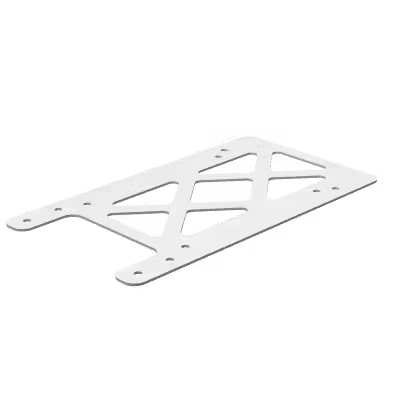

Laser cutting is a precise, efficient method for creating flat patterns, profiles, holes, and cutouts—especially for sheet metal parts and panels. It’s widely used for brackets, enclosures, frames, covers, and components that require consistent geometry and clean edge quality.

LK Tools can support both prototypes and repeat production runs. If your part has tight tolerances, critical hole patterns, or cosmetic requirements, include that in your RFQ. Our team can review manufacturability and recommend adjustments to reduce cost and improve yield.

Metal laser cutting is commonly used for steel, stainless steel, and aluminum sheet components. It provides high accuracy and repeatability for profiles, slots, and hole patterns—ideal for assemblies and formed sheet metal parts.

For a list of the metal materials supported by Xometry’s metal laser cutting service, see below. Other materials may also be available for quote.

Laser cutting can also be used for certain plastics and sheet polymers when edge quality, detail, and speed matter. Material choice is important—some plastics cut cleanly, while others may melt, discolor, or release fumes. LK Tools will confirm suitability based on material type, thickness, and geometry.

Acrylic (PMMA) is one of the most common materials for laser cutting because it produces clean edges and supports high detail. It’s widely used for covers, light guides, display components, and cosmetic panels.

Wood laser cutting is often used for prototypes, templates, packaging inserts, and lightweight panel parts. Results depend on wood type, thickness, and desired edge appearance.

Note: If you need precise fit or assembly features, include tolerances and expected usage in your RFQ.

If laser cutting isn’t the best fit for your design, thickness, or material, LK Tools can recommend alternatives based on performance and cost.

The most common laser cutter type because of their relatively high energy efficiency and high power output ratio. Best suited for cutting, boring, and engraving services.

Nd lasers have a high energy, and are used for boring and welding.

A disadvantage of Nd lasers are their low repetition efficiency.

Nd:Yag Lasers are high powered lasers and suitable for cutting thick materials. Nd:Yag lasers can be used for boring, welding, and engraving.

A disadvantage of Nd:Yag lasers is that they are more expensive to operate.

Free shipping available for domestic laser cutting orders

Laser cutters can cut many materials with high precision, making it perfect for preparing flat patterns or material blanks.

The range of materials available, low cost per unit, and speed of production makes laser cutting a great option for prototyping.

Large format cutting, vast material options, and high throughput have made laser cutting a favorable technology for end-use parts.

Laser Cutting produces highly durable parts well-suited for both functional laser-cut prototypes and end-use production.

All sheet metal parts are built on-demand and with lower setup costs compared to other manufacturing processes. Depending on your needs, order as little as a single prototype up to 10,000 production parts.

Choose from a variety of materials across a wide range of strength, conductivity, weight, and corrosion resistance.

Combining the latest cutting, bending, and punching with automated technologies, Xometry provides instant sheet quotes that can often ship the same week.

Achievable tolerance depends on material type, thickness, geometry, and cut strategy. For critical dimensions and hole patterns, include a 2D drawing with explicit tolerances or GD&T. LK Tools can support inspection reports upon request.

Laser cutting uses a focused beam to melt, burn, or vaporize material along a programmed path, producing accurate cuts with minimal mechanical force on the part. Because the process is digitally controlled, it can produce consistent results across prototypes and repeat orders.

Cut quality depends on factors such as thickness, material composition, and edge finish requirements. LK Tools reviews your geometry and requirements to choose an appropriate cutting approach and ensure your parts meet functional and cosmetic expectations.

Laser cutting is a practical option when you need speed, repeatability, and complex 2D geometry without investing in tooling. It’s especially effective for sheet metal components that will be bent, assembled, or integrated into larger systems.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get your laser cut parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential