Custom sheet metal parts for prototypes and production—laser cutting, bending, and assemblies. LK Tools supports engineering teams with fast quoting, manufacturability feedback, and reliable delivery.

STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

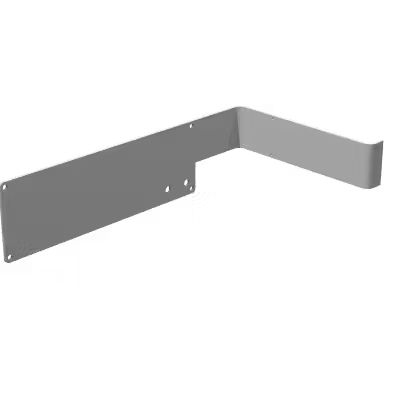

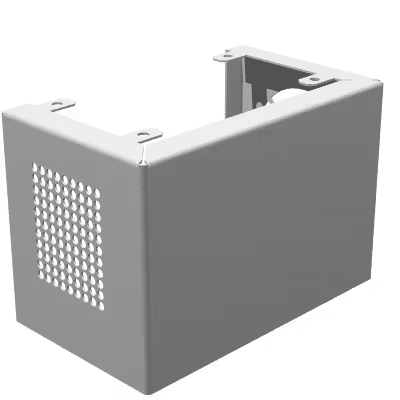

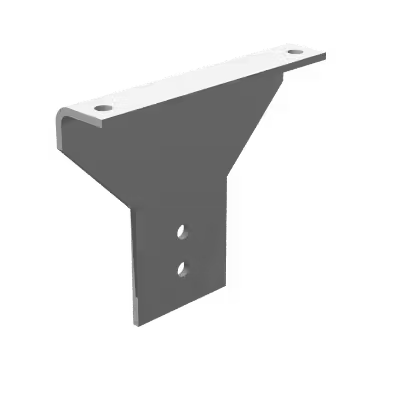

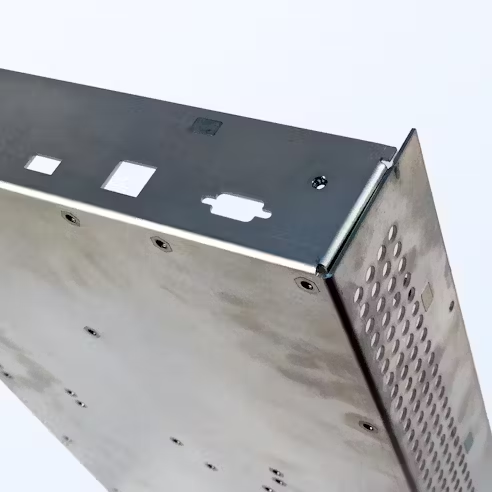

Sheet metal fabrication is a fast and scalable way to produce brackets, panels, enclosures, frames, and structural components. The process typically combines cutting (laser/waterjet/punch), forming (bending), and secondary operations such as PEM hardware insertion, welding, and finishing.

LK Tools supports programs from early prototypes to repeat low-volume production. If your design has tight flatness requirements, cosmetic surfaces, or critical hole patterns, our team can provide practical D practical way to produce strong, lightweight parts with excellent repeatability—especially for enclosures, brackets, panels, and chassis components. LK Tools supports programs from rapid prototypes through low-volume and production runs with controlled processes and clear communication.

Our team can review your design for bend feasibility, hole-to-bend rules, hardware placement, and assembly considerations. If cost, lead time, or cosmetic requirements are critical, we’ll recommend options such as alternative materials, thickness changes, or simplified features to improveFM guidance to improve yield and reduce cost.

For higher-volume programs, stamping can reduce piece cost once tooling is justified.

Sheet metal forming transforms a flat cut blank into a 3D part using bending and related forming operations. Because the material starts as sheet, forming is efficient for producing stiff, lightweight parts with consistent dimensions—especially when designs follow standard bend rules.

Bend radius, material thickness, and grain direction can influence strength and final shape. For parts with critical fit features, LK Tools can review your drawings and confirm bend allowances and dimensional expectations before production.

Aluminum 1100-H14

Aluminum 5052-H32

Aluminum 6061

Copper 101

Copper C110

Copper C110, H02

Copper 260 (Brass)

Bronze 220

Bronze 510

Stainless steel 301

Stainless steel 304

Stainless Steel 304 #4 brushed

Stainless Steel 304, #8 mirror polish

Stainless steel 316/316L

Stainless Steel 316, #4 brushed

Steel 1018 (Low Carbon)

Steel 1045 (Hot Rolled)

Steel A569/ASTM A1011 (Hot Rolled)

AZ55 Galvalume

A653 Galvanized

1095 Spring Steel

Steel A36

Steel A36, pickled and oiled

Steel A366/1008

Inconel 625

Nickel Alloy 200

Nickel Alloy 400

Titanium (Grade 2)

Titanium 6AI-4V (Grade 5)

Selecting the right finish helps protect sheet metal parts from corrosion and wear while improving cosmetic appearance. LK Tools offers common finishing options for brackets, enclosures, panels, and structural components. Availability depends on material, thickness, and your functional requirements—share your target color, texture, and environment of use (indoor/outdoor, chemical exposure, salt fog, etc.) and we’ll recommend the best finishing route.

Minimal post-processing or treatment on parts is done.

The part surface is left with a smooth, matte appearance.

Type II (MIL-A-8625/MIL-PRF-8625, Type II) creates a corrosion-resistant finish. Sheet metal parts can be anodized in different colors—clear, black, red, and gold are most common—and are usually associated with aluminum. Type III (MIL-A-8625, Type III, Class 1/2 “hardcoat”) is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

This sheet metal finish provides corrosion resistance and good conductivity properties. Chem film can be used as a base for paint and can leave surfaces yellow or gold. Adds very little thickness, about 0.00001”-0.00004.” Chem film will conform to MIL-DTL-5541, TYPE I/II.

This is a sheet metal fabrication process where powdered paint is sprayed onto a part that is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic.

A sheet metal fabrication process that provides uniform nickel coating which offers protection from corrosion, oxidation, and wear on irregular surfaces. The finished part will be brighter. Thickness starts at .0001” and this finish conforms to MIL-C-26074.

Gold Plating provides good corrosion and tarnish resistance with excellent solderability. Default application specification is MIL-G-45204 & ASTM B488, CLASS 00, 0, OR 1 (Thickness 0.00002″ – 0.00005″).

Silver offers high solderability and electrical conductivity but is susceptible to tarnish on sheet metal parts. Conforms to AMS QQ-S-365D. Thickness is about 0.00002”- 0.0003.”

Sheet metal can be quickly cut into 2D profile shapes and formed out of a variety of high-strength materials, making it perfect for rapid tooling.

With lead times starting at 3 days, no minimum order volumes, and low-per-unit costs, rapid sheet metal is a great option for prototyping.

Per-unit pricing lowers significantly in production volumes. Combined with end-use materials and high throughput, sheet metal fabrication is a well-known production method.

Upload your CAD and requirements to receive pricing and engineering feedback.

Choose from thousands of possible combinations of sheet metal materials, finishes, tolerances, markings, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential