STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

Medical products demand consistent dimensions, reliable materials, and controlled processes. CNC machining is a strong choice for medical components because it produces accurate features, smooth mating surfaces, and repeatable results in production-grade materials.

LK Tools supports development teams and OEMs with machining services that fit the medical product lifecycle—from early prototypes and engineering builds to validation runs and repeat low-volume production. available upon request.

CNC machining is commonly used for medical devices and lab systems where accuracy, repeatability, and material options are essential.

For implant-related programs, requirements compact handheld equipment to larger systems.

For implant-related or biocompatibility-sensitive projects, material choice, finishing, and documentation requirements are critical. Share vary significantly by material, validation, and compliance needs. Share your specifications and documentation requirements early so we can confirm feasibility and routing.

We machine components used in surgical and diagnostic instruments where fit and finish are important.

Surgical stainless steel and titanium are two of the most commonly used materials in medical CNC machining. 5-axis CNC machining, Swiss lathe, and CNC milling are all applicable processes when CNC machining surgical instruments.

Dental equipment and tooling often require compact geometry and tight fits. We support small precision parts and repeat low-volume runs.

We have extensive CNC capability for the medical manufacturing industry including: 3-axis milling machines, CNC lathes, 5-axis CNC milling machines, and wire EDM machines.

See more information below:

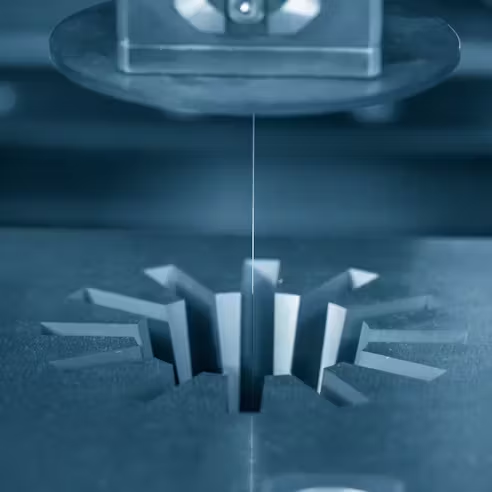

Xometry offers wire EDM medical machining to fabricate medical parts and components. Wire EDM is a non-conventional machining process in which cuts are made with an electrically conductive wire. This results in parts with shallow surface roughnesses (down to 1.5 µm Ra) that satisfy extremely tight tolerances (+0.0025 mm).

Wire EDM is highly applicable for medical CNC machining, as various medical devices like surgical tools and bone plates require precision. This technology is commonly used for the fabrication of plastic injection molds and extrusion dies. Wire EDM can also be used to cut any electrically conductive material.

We offers 5-axis CNC medical machining which has an advantage over simpler 3- and 4-axis machining. It allows parts to be moved about 5 degrees of freedom simultaneously. This enables cutting tools to approach parts from any direction. Consequently, it allows complex shapes that otherwise would not be possible to be cut on a 3- or 4-axis machine to be cut with precision.

5-axis CNC machining is ideal for medical devices such as joint replacements, prostheses, and various surgical and dental instruments—not to mention its use for the fabrication of molds and dies. Common materials used in the medical industry with 5-axis machining include titanium, stainless steel, chromium-cobalt, and aluminum.

We offers Swiss CNC medical machining, a precision manufacturing machine that produces very small parts quickly and accurately. The primary advantage of swiss CNC machines over standard CNC lathes is that multiple cutting operations that would normally require multiple setups can occur simultaneously. This is due to the presence of multiple spindles for cutting tools—as well as the ability to make cuts along the Z-axis of the part. What results, are highly precise, complex parts that otherwise could not be cut on a standard lathe. Swiss CNC medical machining is ideal for round parts such as those found in prostheses, joint replacements, and surgical and dental instruments. Common materials include stainless steel, aluminum, titanium, and chromium-cobalt.

We offers standard 3- and 4-axis medical CNC milling. Medical CNC milling’s advantage is the rapid turnaround of parts and parts that fall within tight tolerances. Common materials include stainless steel, titanium, aluminum, chromium-cobalt, PVC, PEEK, nylon, and PE.

Upload your files and receive a fast response with engineering feedback.

Any material considered acceptable for medical devices must meet high standards of reliability and performance. Below are some common materials used for medical CNC machining:

Common metals (examples):

Common plastics (examples):

Medical CNC machining with Xometry is easy. Our AI-powered instant quote tool allows you to quickly see the feasibility of manufacturing your part, while our extensive manufacturing network ensures your parts will be made to exact specifications, fast.

For more information see below:

The fabrication of medical devices and components requires precision. With Xometry, precise components that satisfy exceptionally tight tolerances (down to +0.0025 mm) are well within our capabilities. Our robust manufacturing capability and network mean that seemingly any part can be fabricated. Whether it’s surgical and dental tools, components for medical devices, or parts for prostheses, our wire EDM, 5-axis CNC machines, Swiss lathes, and standard CNC milling and lathe machines will ensure your parts satisfy regulatory standards and are made to exact specifications every time.

The medical industry’s demand for high-quality parts also requires fast delivery to satisfy their customers. With Xometry, our expansive manufacturing capability and extensive network of partner manufacturers (over 10,000 vetted manufacturing facilities around the world), allow the fabrication and shipping of parts significantly faster than the competition. Whether for prototyping or scaling up to mass production, rapid turnaround of parts is standard.

When working with Xometry, businesses are no longer confined to the suppliers local to them. Our network of 10,000+ vetted manufacturing facilities in 44 states and 22 countries around the world means our manufacturing capabilities and capacity are seemingly endless. Our capabilities aren’t limited to just CNC machining for the medical industry; they also include sheet metal fabrication, injection molding, additive manufacturing, and various finishing processes including anodization, passivation, and powder coating. Whatever your medical manufacturing project is, Xometry has the tools and resources available to ensure your project is successful.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.

All uploads are secure and confidential