Quality Prototypes and Production Parts. 1-Day Expedite. Free Shipping on All US and International Orders. ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D Certified.

STEP | STP | SLDPRT | STL | DXF | IPT | 3MF | 3DXML | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

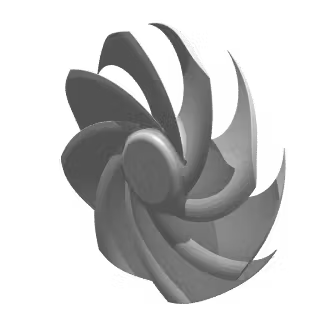

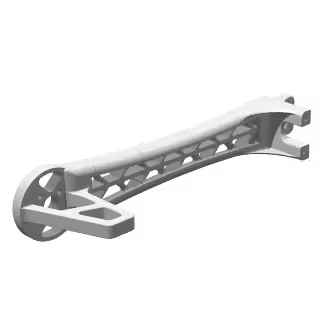

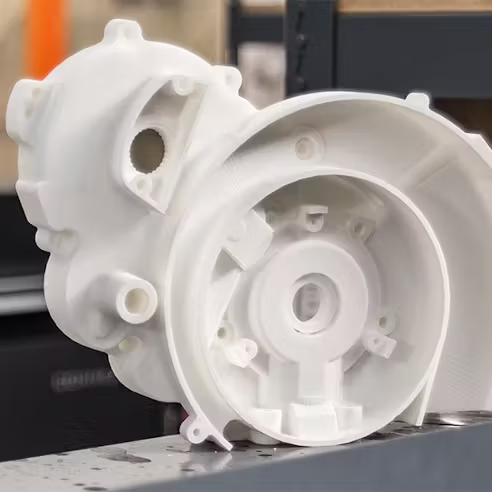

Selective laser sintering, or SLS, is a powerful 3D printing technology that produces highly accurate and durable parts, making it one of the most popular and cost-effective options for creating complex industrial-grade structures. Our primary SLS printing materials are nylon and its variants, including glass-filled, aluminum-filled, and carbon-filled nylons, as well as flame-retardant composites.

As an additive manufacturing technology, SLS uses a high-power laser (like a carbon dioxide laser) to fuse small particles of plastic powder into a solid structure. The laser selectively sinters the material based on a 3D CAD file, layer by layer, until the part is complete.

Color options of dye black, blue, green, red, or yellow. Batch to batch consistency may vary slightly with black being the most consistent. Dye penetrates ~0.010″ deep.

An automated post-processing technology (AMT PostPro3D) that achieves a high-quality surface finish. Vapor smoothing brings most surfaces from a matte to a semi-gloss. Vapor smoothing also seals the surface, enhances mechanical properties, and provides a consistent cosmetic finish for production. Vapor smoothed parts can be dyed.

Standard finish with the addition of abrasive media tumbling. These parts will have reduced grow lines and sharp edges may be softened by the tumbling process. The parts are left with an eggshell finish.

Standard finish with a secondary copper + nickel plating processes adding 0.004″-0.006″ nickel coating. Nickel plating adds durability, stiffness, and wear resistance but is not considered cosmetic. Finish is rough nickel.

We provides additional SLS finishing and customization options upon request.

Our vapor smoothing process can give your SLS 3D printed parts an exceptional, near-injection-molded surface finish. This automated, hands-off technology creates a sealed, semi-gloss surface that makes parts watertight and more durable. The enhanced surface is also perfect for color-dyeing. Vapor smoothing increases the overall performance of 3D printed parts, improving ultimate tensile strength and elongation to break.

Free shipping available for domestic 3D printing orders.

The speed and versatility of FDM lets engineers create physical snapshots of their designs.

An FDM machine can be used to create durable prototypes that withstand thermal, chemical, and mechanical stress.

The high accuracy and consistency of SLS makes it an ideal way to build large quantities of discrete or customized parts.

Parts can typically be shipped in 3-4 days, allowing for faster design iterations and speed to market.

SLS is capable of producing end-use parts on-demand, increasing throughput.

Geometries can be built more easily due to the 3D printing process, adding complexity without additional cost.

SLS can make a single part or component as easily as dozens of production pieces.

We use the latest generation of SLS technologies to meet tolerances of +/- 0.010” or +/- 0.002” per inch, whichever is greater. Please see our Manufacturing Standards for more details.

Our quick reference guides let you quickly compare different 3D printing processes!

The Basics Of Selective Laser Sintering

Selective laser sintering (SLS) is a powder bed fusion 3D printing technology that creates highly accurate and durable parts. Both SLS and its metal-focused counterpart, DMLS, work by using a laser to fuse powdered material based on a 3D model. Our service specializes in nylon or polyamide powder parts.

The Benefits Of Working With K Tools Inc.’s SLS Printing Service

Our wide network of machine shops contains a broad range of dedicated quick-turn SLS partners with a variety of high-quality material capabilities and finishing systems. Finishing options include color dyeing, painting, and plating to meet your project’s needs. We can help you source the parts you need at a competitive price, from low-volume prototyping to high-volume production.

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

All uploads are secure and confidential