High-Quality, Large Format FDM 3D Printing. 1-Day Expedite Available. Free Shipping on All US and International Orders.

STEP | STP | SLDPRT | STL | DXF | IPT | 3MF | 3DXML | PRT | SAT files

All uploads are secure and confidential.

Xometry’s Instant Quoting Engine is covered by U.S. Pat. Nos. 11,086,292, 11,347,201, 11,693,388, 11,698,623, 12,099,341, and 12,189,361. Other patents pending.

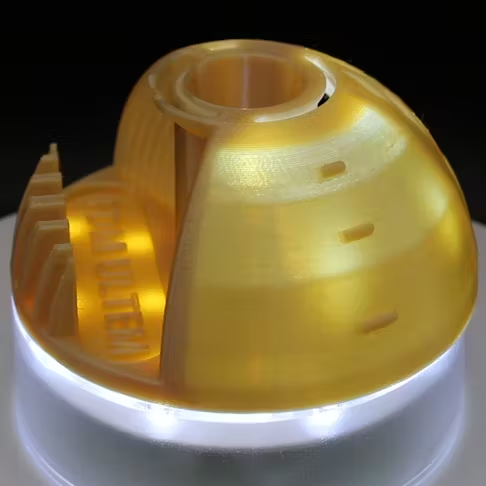

Fused Deposition Modeling (FDM) is an additive manufacturing technology known for its speed, accuracy, and cost-effectiveness. The FDM process works by extruding a melted filament of thermoplastic material through a heated nozzle to create a part layer-by-layer. This method is incredibly versatile and can produce parts in as fast as one day.

K Tools Inc.’s FDM service offers large build volumes up to 24″ x 36″ x 36″ on our industrial platforms. We offer a wide selection of production-grade thermoplastic materials for any 3D printing project. Our material library includes general-purpose ABS and ASA, as well as high-performance, heat-resistant ULTEM.

Our available materials include Prototyping PLA, a low-cost, rigid thermoplastic. Our PLA offering comes in four standard colors (black, red, white, and blue) and is great for developing concept models or low-wear indoor products.

Because of its lower overhead and material cost, PLA is typically less than half the price of our other FDM options. In exchange, there are some trade-offs with lower strength, heat deflection, and dimensional accuracy compared to other plastics. Keeping that in mind, PLA provides a great option for vibrant colors and quick lead times.

FDM parts are built with support material that is removed during post-processing. The part surfaces are left with fine layer lines.

Xometry can provide additional processing such as painting or vapor smoothing to meet your needs.

The speed and versatility of FDM lets engineers create physical snapshots of their designs.

An FDM machine can be used to create durable prototypes that withstand thermal, chemical, and mechanical stress.

High-performance materials make FDM ideal for producing jigs, fixtures, and production tooling.

We use the most advanced industrial FDM printers designed to meet tolerances of +/- a single build layer thickness for the first inch and +/- .002″ for every inch thereafter.

Choose from a wide range of real, production-grade thermoplastics for durable and functional parts.

Our printers support large part creation, enabling bigger and more ambitious projects.

FDM printing is a cost-effective additive manufacturing process, especially for rapid prototyping and low-volume production.

FDM uses the same types of thermoplastics found in traditional manufacturing for high-performance applications.

FDM 3D printed parts can be built up to 24″ x 36″ x 36″. Stratasys Fortus 400/450-series machines will produce parts up to 16″ and Stratasys Fortus 900MC or F900 platforms are used for parts larger than 16″. Prototyping PLA is built on Prusa MK3S/MK4 or Bambu Lab X1C desktop FFF machines with a build volume of 9.8″ x 8.3″ x 8.3. General tolerances apply before secondary finishing or post-processing unless otherwise specified. To learn more tips about FDM 3D printing, check out our Fused Deposition Modeling (FDM) Design Guide. Applies to US-based production only.

Our quick reference guides let you quickly compare different 3D printing processes!

With FDM technology, a spool of thermoplastic filament is fed into an extruder, which melts the polymer to a semi-liquid state. The extruder deposits the material through a nozzle onto a build platform. The printer software first converts the 3D CAD file into individual slices, which essentially become the machine’s instructions. The printer head follows a pre-determined path to deposit the material for each layer. After one layer is complete, the platform moves to begin the next, and the process is repeated until the part is finished.

FDM is among the most accessible and recognizable additive manufacturing technologies worldwide. Known for its precision in creating three-dimensional structures from a choice of feedstock materials, it’s a favorite among 3D printing hobbyists and large-scale manufacturers alike.

The range of filaments available for fused deposition modeling includes:

Choose from millions of possible combinations of materials, finishes, tolerances, and certifications for your order.

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

We are ISO 9001, ISO 13485, and AS9100D certified. Our rigorous qualification process ensures top quality.

All uploads are secure and confidential