Precision Manufacturing Meets Thermal Excellence.

From advanced cooling systems to multi-process manufacturing—we engineer, integrate, and deliver the innovations that power tomorrow’s technology.

📊 20+ Years of Excellence 🌍 50M+ Parts Delivered

🏭 Global Manufacturing + Dallas Warehouse ⚡ 24/7 Engineering Support

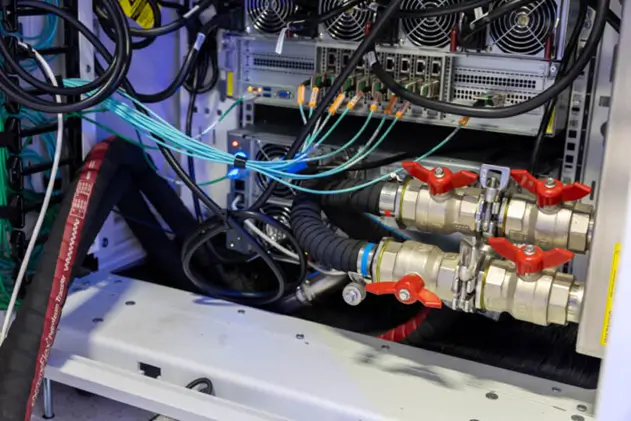

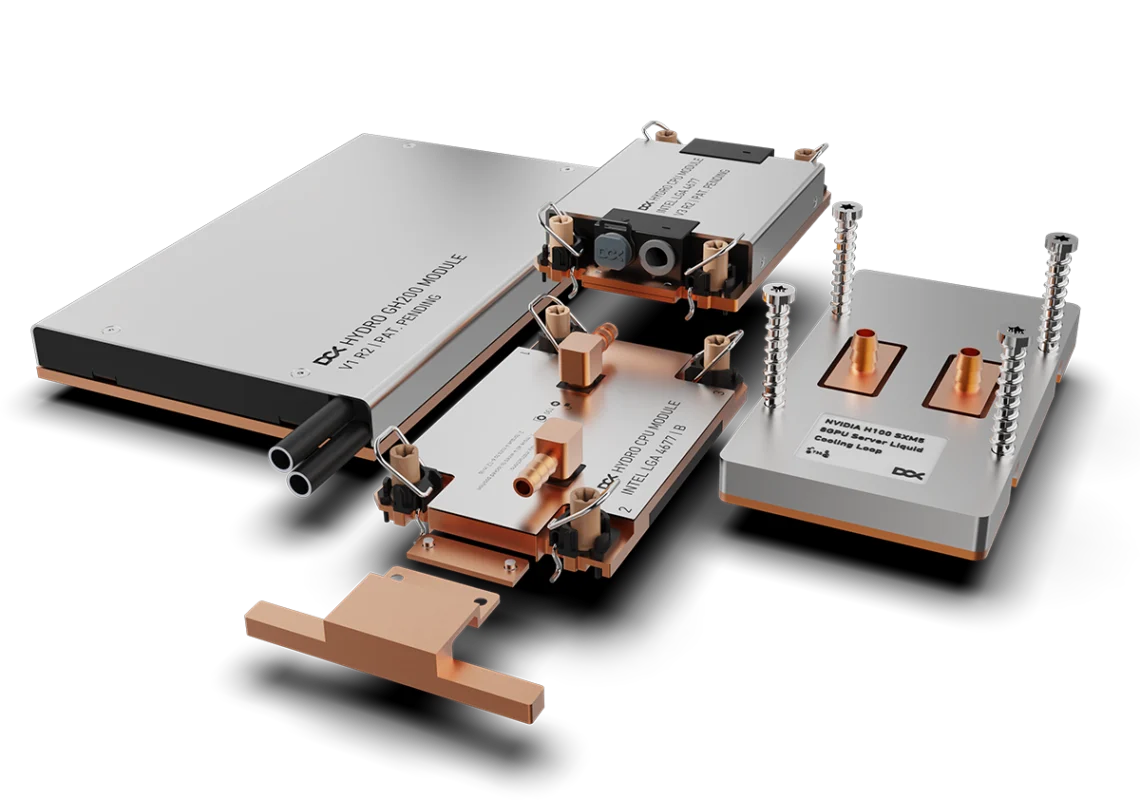

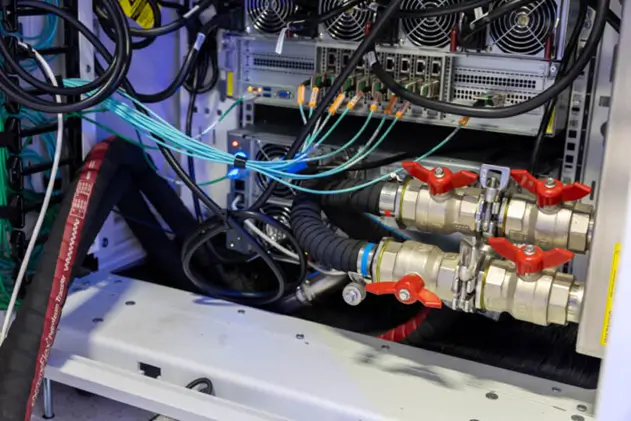

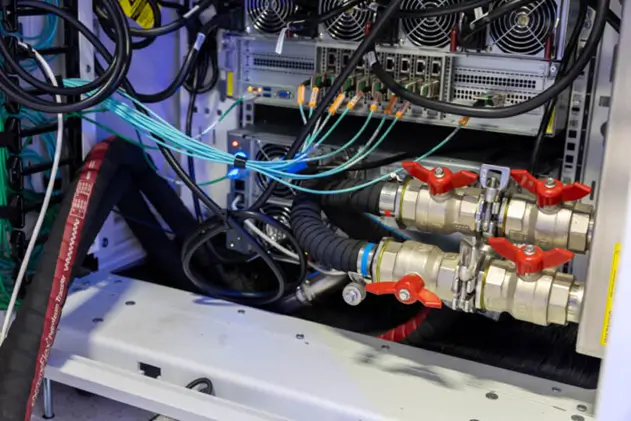

Data Center Liquid Cooling

Medical Devices

Aerospace & Power Electronics

Why Leading Innovators Choose Us

Thermal Engineering Expertise That Sets Us Apart

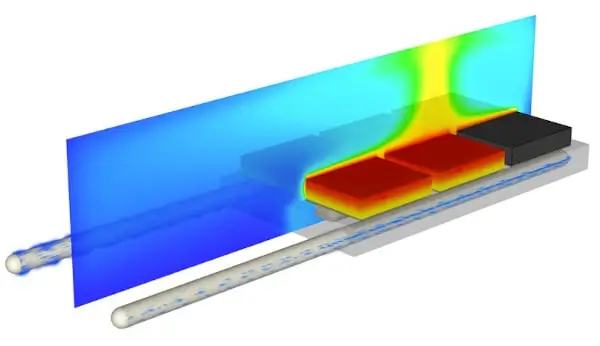

Most manufacturers can’t solve your cooling challenges. We specialize in advanced thermal management—liquid cold plates, vapor chambers, heat pipes, and integrated cooling assemblies—designed, tested, and manufactured in-house.

Our thermal solutions cool:

- AI/GPU data center clusters generating 1000W+ per chip

- EV battery systems requiring precise temperature control

- Power electronics (IGBT, SiC) in charging stations and inverters

- High-performance computing and edge servers

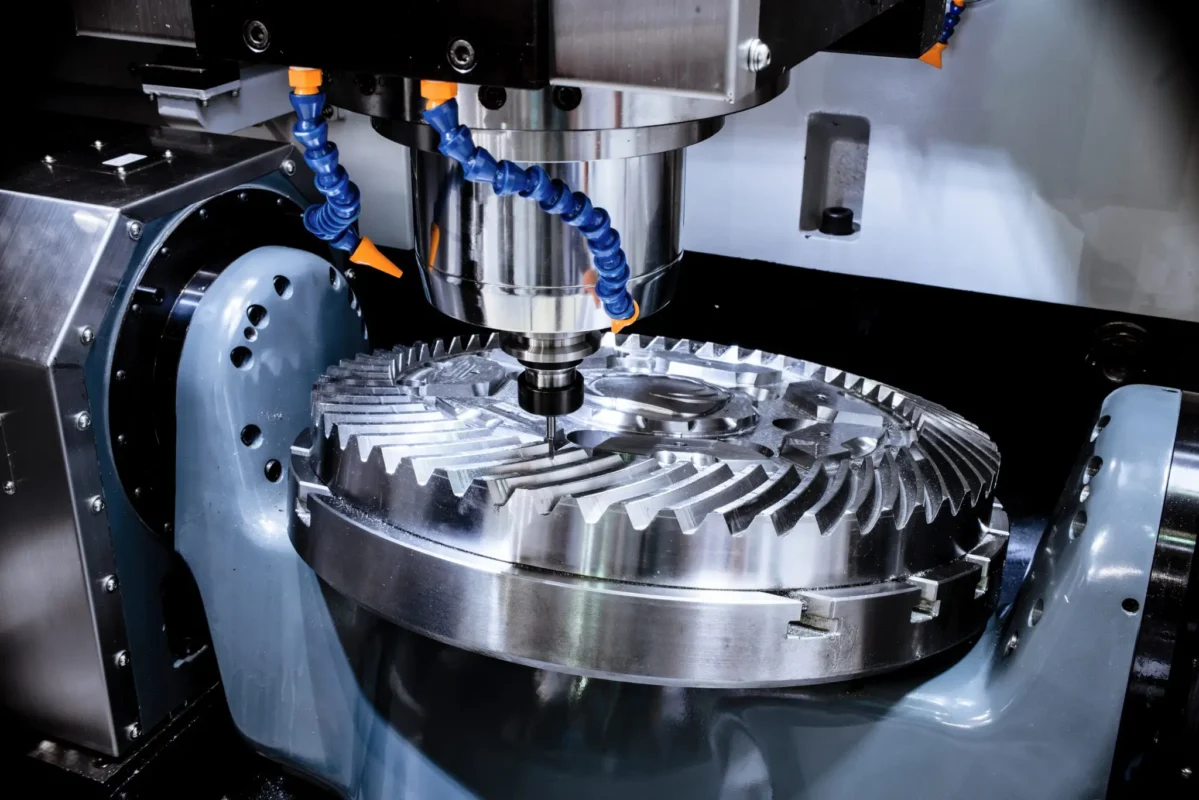

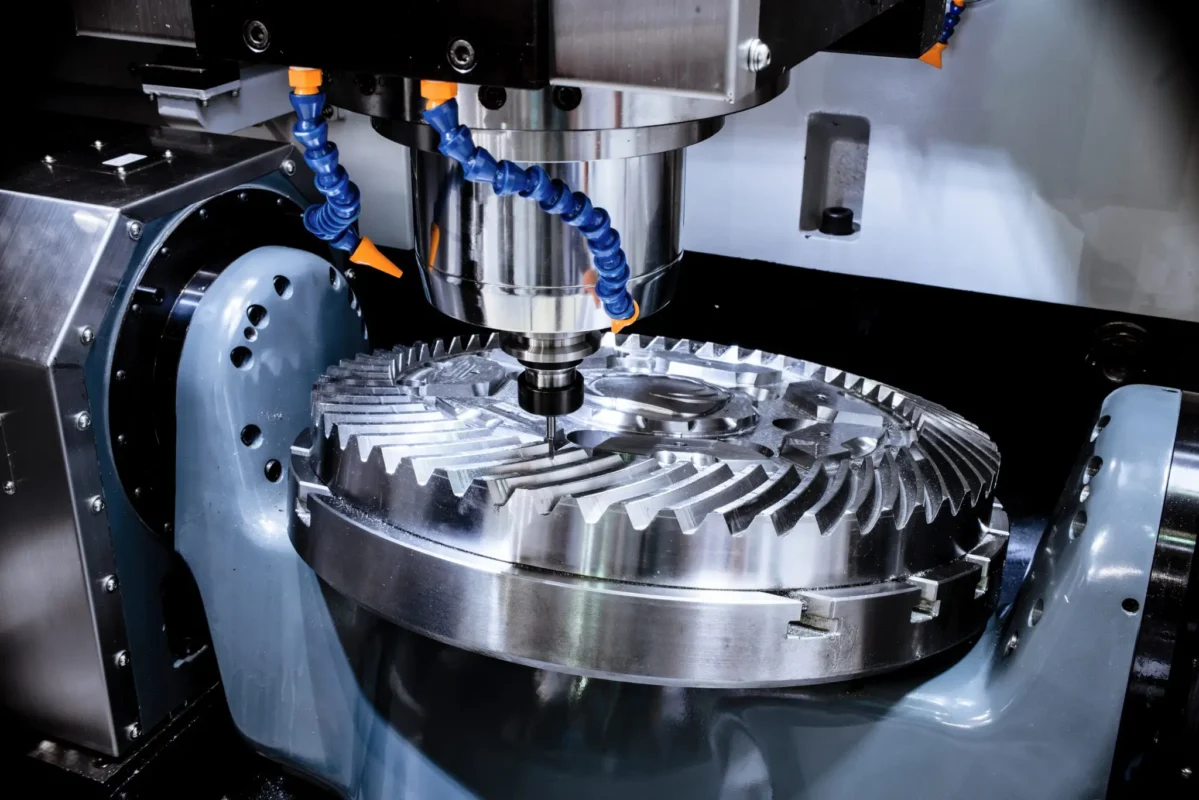

Multi‑Process Integration Under One Roof

Stop juggling multiple vendors. 10+ manufacturing processes in a single, vertically integrated facility.

Injection Molding

Die Casting

Rubber & Silicone Molding

Sheet Metal & Stamping

Casting & Forging

Welding (Laser, TIG, MIG, FSW)

Surface Finishing

Assembly & Integration

Testing & Validation

Engineering‑Driven Cost Optimization

Our DFM engineers don’t just quote your design—we optimize it before you cut metal.

- Material substitution with performance‑equivalent, lower‑cost options

- Process selection (CNC vs. casting vs. molding)

- Tolerance rationalization on non‑critical features

- Part consolidation to reduce assembly and BOM

- Volume break analysis from 10 to 100,000+ units

Case in point: 37% per‑unit cost reduction on an automotive sensor housing by shifting from 5‑axis CNC to die casting + secondary machining.

Global Manufacturing + Local Support

Asia Manufacturing Hub: Cost‑effective, high‑volume production with ISO 9001/14001/45001, IATF 16949, AS9100, and ISO 13485 certifications.

U.S. Dallas Warehouse: Local inventory, fast domestic shipping, technical support, and after‑sales service for North American customers.

From CAD to Your Dock in Record Time

Standard lead times designed around fast iteration and scalable production.

Upload

Share your CAD and requirements securely under NDA.

DFM Feedback

Receive actionable DFM recommendations within 24 hours.

Quote in 24 Hours

Transparent pricing with volume breaks and lead time options.

Rapid Prototyping

Prototype parts in 1–2 weeks; soft tooling in 2–3 weeks.

Scale to Production

Production tooling in 4–8 weeks; mass production in 2–4 weeks per order.

Typical quote turnaround: <24 hours

Trusted Cooling for High‑Power Systems

The partner of choice for advanced thermal management in AI, EV, and power electronics.

- Cools AI/GPU chips and power modules at 1000W+

- Leak‑free liquid cold plates using friction stir welding

- CFD‑driven design with lab‑verified thermal resistance

- Complete stack: cold plates, vapor chambers, heat pipes, manifolds, and integrated modules

Includes: Liquid cold plates, vapor chambers, heat pipes, manifolds, integrated cooling assemblies.

Precision Components, Production‑Ready

Complex mechanical parts and assemblies, manufactured and finished under one roof.

- Tight tolerances to ±0.005 mm on critical features

- Metals, plastics, rubber, and silicone supported

- Housings, brackets, seals, and enclosures from a single supplier

- Volumes from 10 prototypes to 10M+ units per year

Includes: CNC machining, injection molding, die casting, rubber/silicone molding, sheet metal, assembly.

From First Article to Full Ramp

One partner from EVT prototypes through mass production.

- Rapid CNC and soft tooling in 1–2 weeks

- EVT/DVT/PVT builds with reliability and functional testing

- PPAP, FAI, and Cpk for regulated industries

- Seamless ramp from the first 10 parts to the first 1,000,000

Ideal for: New platforms, design transfers, and multi‑year production programs.

Factory to Dock, Without Surprises

Global manufacturing, local inventory, and flexible logistics.

- EXW, FOB, DAP, and DDP shipping options

- VMI, JIT, and buffer stock via Dallas warehouse

- Custom packaging and drop‑tested solutions

- Visibility into lead times, orders, and inventory

Covers: Global shipping, customs support, warehousing, and fulfillment.

Design It for Manufacturability from Day One

Manufacturing engineers embedded into your design process.

- 24‑hour DFM feedback on every quote

- Material, process, and tolerance optimization

- CFD and FEA for thermal and structural performance

- Clear markups and stack‑up analysis for your team

Available with: Every prototype and production quote.

Fast Prototypes, Real‑World Results

Turn concepts into functional hardware you can test.

- Prototype parts in as little as 1–2 weeks

- Flexible materials and processes for early exploration

- Thermal and mechanical prototypes that reflect final performance

- Clear path from prototype methods to production tooling

Best for: New product ideas, feasibility studies, early demos.

Production That Grows with Your Business

Manufacturing support for fast‑moving startups and scale‑ups.

- Volume‑flexible: runs from hundreds to tens of thousands

- Tooling strategy matched to each growth stage

- Rapid response to design changes and ECOs

- Documentation and quality that satisfy investors and enterprise customers

Ideal for: VC‑backed hardware, med‑tech, robotics, EV, industrial IoT.

Extra Capacity for Established OEMs

Add capacity or launch new programs without overloading existing plants.

- IATF 16949, AS9100, and ISO 13485 ready

- Dual‑sourcing and interchangeable processes to avoid single‑point failures

- PPAP, FAI, and Cpk reporting for critical parts

- Multi‑year supply with consistent quality metrics

Best for: Automotive, aerospace, medical, and industrial OEMs.

Stronger, Safer Supply Chains

Reduce risk on critical components.

- Alternate materials and processes for key part families

- Local safety stock in Dallas to protect your lines

- Lead‑time and capacity transparency for planners

- Structured risk‑reduction plans for high‑impact SKUs

Designed for: Operations and supply chain teams managing uptime.

Unlock More Power with Better Cooling

Upgrade thermal performance without a complete redesign.

- Higher‑performance drop‑in cold plates and heat sinks

- CFD‑driven improvements in thermal resistance and pressure drop

- Better alloys, fin designs, and TIM strategies

- Field‑proven in EV, data center, and industrial systems

Perfect for: Mid‑life refreshes, new power levels, and hot‑spot failures.

Thermal Solutions

Trusted Cooling for High‑Power Systems

The partner of choice for advanced thermal management in AI, EV, and power electronics.

- Cools AI/GPU chips and power modules at 1000W+

- Leak‑free liquid cold plates using friction stir welding

- CFD‑driven design with lab‑verified thermal resistance

- Complete stack: cold plates, vapor chambers, heat pipes, manifolds, and integrated modules

Includes: Liquid cold plates, vapor chambers, heat pipes, manifolds, integrated cooling assemblies.

Mechanical Manufacturing

Trusted Cooling for High‑Power Systems

The partner of choice for advanced thermal management in AI, EV, and power electronics.

- Cools AI/GPU chips and power modules at 1000W+

- Leak‑free liquid cold plates using friction stir welding

- CFD‑driven design with lab‑verified thermal resistance

- Complete stack: cold plates, vapor chambers, heat pipes, manifolds, and integrated modules

Includes: Liquid cold plates, vapor chambers, heat pipes, manifolds, integrated cooling assemblies.

Prototype to Production

From First Article to Full Ramp

One partner from EVT prototypes through mass production.

- Rapid CNC and soft tooling in 1–2 weeks

- EVT/DVT/PVT builds with reliability and functional testing

- PPAP, FAI, and Cpk for regulated industries

- Seamless ramp from the first 10 parts to the first 1,000,000

Ideal for: New platforms, design transfers, and multi‑year production programs.

Logistics & Fulfillment

Factory to Dock, Without Surprises

Global manufacturing, local inventory, and flexible logistics.

- EXW, FOB, DAP, and DDP shipping options

- VMI, JIT, and buffer stock via Dallas warehouse

- Custom packaging and drop‑tested solutions

- Visibility into lead times, orders, and inventory

Covers: Global shipping, customs support, warehousing, and fulfillment.

Prototype to Production

From First Article to Full Ramp

One partner from EVT prototypes through mass production.

- Rapid CNC and soft tooling in 1–2 weeks

- EVT/DVT/PVT builds with reliability and functional testing

- PPAP, FAI, and Cpk for regulated industries

- Seamless ramp from the first 10 parts to the first 1,000,000

Ideal for: New platforms, design transfers, and multi‑year production programs.

Fast Prototypes, Real‑World Results

Turn concepts into functional hardware you can test.

- Prototype parts in as little as 1–2 weeks

- Flexible materials and processes for early exploration

- Thermal and mechanical prototypes that reflect final performance

- Clear path from prototype methods to production tooling

Best for: New product ideas, feasibility studies, early demos.

Production That Grows with Your Business

Manufacturing support for fast‑moving startups and scale‑ups.

- Volume‑flexible: runs from hundreds to tens of thousands

- Tooling strategy matched to each growth stage

- Rapid response to design changes and ECOs

- Documentation and quality that satisfy investors and enterprise customers

Ideal for: VC‑backed hardware, med‑tech, robotics, EV, industrial IoT.

Extra Capacity for Established OEMs

Add capacity or launch new programs without overloading existing plants.

- IATF 16949, AS9100, and ISO 13485 ready

- Dual‑sourcing and interchangeable processes to avoid single‑point failures

- PPAP, FAI, and Cpk reporting for critical parts

- Multi‑year supply with consistent quality metrics

Best for: Automotive, aerospace, medical, and industrial OEMs.

Stronger, Safer Supply Chains

Reduce risk on critical components.

- Alternate materials and processes for key part families

- Local safety stock in Dallas to protect your lines

- Lead‑time and capacity transparency for planners

- Structured risk‑reduction plans for high‑impact SKUs

Designed for: Operations and supply chain teams managing uptime.

Unlock More Power with Better Cooling

Upgrade thermal performance without a complete redesign.

- Higher‑performance drop‑in cold plates and heat sinks

- CFD‑driven improvements in thermal resistance and pressure drop

- Better alloys, fin designs, and TIM strategies

- Field‑proven in EV, data center, and industrial systems

Perfect for: Mid‑life refreshes, new power levels, and hot‑spot failures.

What We Make

Thermal Products

Liquid cold plates, skived heat sinks, heat pipes, vapor chambers, and fully integrated cooling module assemblies.

Custom Components

CNC machined parts, injection molded plastics, die-cast housings, rubber/silicone seals, extrusions, and sheet metal enclosures.

Materials & Finishing

Metals, engineering plastics, and elastomers with anodizing, powder coating, plating, polishing, and laser marking finishes.

Tooling & Molds

Injection molds, die-casting tools, rubber/silicone molds, extrusion dies, stamping tools, and custom welding fixtures.

Thermal Products

Liquid cold plates, skived heat sinks, heat pipes, vapor chambers, and fully integrated cooling module assemblies.

Custom Components

CNC machined parts, injection molded plastics, die-cast housings, rubber/silicone seals, extrusions, and sheet metal enclosures.

Materials & Finishing

Metals, engineering plastics, and elastomers with anodizing, powder coating, plating, polishing, and laser marking finishes.

Tooling & Molds

Injection molds, die-casting tools, rubber/silicone molds, extrusion dies, stamping tools, and custom welding fixtures.

Powering Innovation Across Industries

Automotive & EV

Battery thermal management, power electronics cooling, lightweighting, IATF 16949 certified production.

Robotics & Automation

Motor controller heat sinks, precision gearbox housings, servo drive thermal management.

Medical Devices

ISO 13485 certified, biocompatible materials, cleanroom assembly, FDA traceability.

Outdoor / Sporting / Tactical

Anodized aluminum components, weather-resistant coatings, lightweight structures.

Photography / Audio

Precision mounts, vibration damping components, speaker structural parts.

Aerospace & UAV

AS9100 certified, lightweight aluminum/titanium parts, avionics cooling, ITAR compliance.

Power Electronics

IGBT/SiC cold plates, EV charging station enclosures, high-power thermal solutions.`

Marine / Rail / Metro

Corrosion-resistant materials, IP67/IP68 sealing, vibration-resistant designs.

Consumer Electronics

Ultra-thin vapor chambers, precision aluminum chassis, high-volume production.

Custom OEM Projects (NDA)

Confidential product development, white-label manufacturing, IP protection.

Our Manufacturing Capabilities

We don’t just make parts. We engineer complete solutions.

Manufacturing Processes

CNC Machining · Injection Molding · Rubber & Silicone Molding · Die Casting · Extrusion · Sheet Metal Fabrication · Casting & Forging · Welding · Assembly

Testing & Validation

Dimensional Inspection (CMM, 3D Scan, SPC) · Mechanical Testing · Environmental Testing · Thermal Performance Testing · Reliability Testing · FAI/PPAP/Cpk Documentation

Quality & Certifications

ISO 9001 · ISO 14001 · ISO 45001 · IATF 16949 (Automotive) · AS9100 (Aerospace) · ISO 13485 (Medical) · RoHS · REACH · UL · FDA

Trusted by Innovators Worldwide

Director of Hardware Engineering

Fortune 500 Data Center Company

“We’ve worked with dozens of contract manufacturers. Your Company is the only one that truly acts as an engineering partner, not just a vendor.”

VP of Operations

Leading EV Manufacturer

Founder & CTO

Medical Device Startup

Quality Manager

Surgical Instrument Manufacturer

Why Leading Innovators Choose Us

Engineering-First Approach

Our in-house team of mechanical, thermal, and manufacturing engineers collaborates with you from concept through production.

True Vertical Integration

Control your supply chain. We own machining, molding, casting, finishing, and assembly—eliminating vendor risk.

Thermal Expertise

Unlike commodity manufacturers, we specialize in advanced thermal management. If your product generates heat, we solve it.

Global + Regional Support

Asia facilities for cost-effective production plus a Dallas warehouse for fast U.S. fulfillment—best of both worlds.

ISO-Certified Quality

ISO 9001 · ISO 14001 · ISO 45001 · IATF 16949 · AS9100 · ISO 13485 · RoHS · REACH · UL compliant systems.

Speed Without Compromise

Rapid quoting, fast-track prototyping, and agile production scaling. We move at the speed of innovation.

Ready to Engineer Your Next Innovation?

Whether you’re launching a new product or scaling an existing one, we’re here to help.